Laser cutting has been around since the 60’s, but it’s become incredibly prominent in an industrial world focused on faster, more precise, and high-volume processes. CNC laser cutting machine equipment has entered a phase of strong expansion with an annual growth rate of more than 30%. This is a result of the rapid development of the equipment production industry.

Technology advancement and lower pricing are making custom metal cutting available mainstream. Once used solely for manufacturing, laser cutting is widely used in hospitals, schools, and even homes. Let’s explore the different reasons for the importance of laser cutting machines. Also, in order to meet your custom metal cutting needs, Steelway Laser Cutting is here for you.

Achieve the Best Results with Steelway Laser Cutting

You should be aware that manufacturers of laser cutting machines are in fierce competition with one another. Regardless of your situation, we have a solid solution for your specific needs. Steelway Laser Cutting can help take the pressure off navigating this decision and help you decide if custom metal fabrication is worth outsourcing or investing in. We’re here to help you determine what’s best for you.

Everything You Need to Know About CNC Laser Cutting

CNC (Computer Numerical Control) machining is a subtractive technology whereby parts are created by removing material from a solid block, or workpiece, using a variety of cutting tools.

The basic process of a CNC laser cutter can be broken down into three steps.

- The engineer designs the CAD model of the part.

- The machinist turns the CAD file into a CNC program and sets up the machine.

- Lastly, the CNC system executes all machining operations with little supervision, removing material and creating the part.

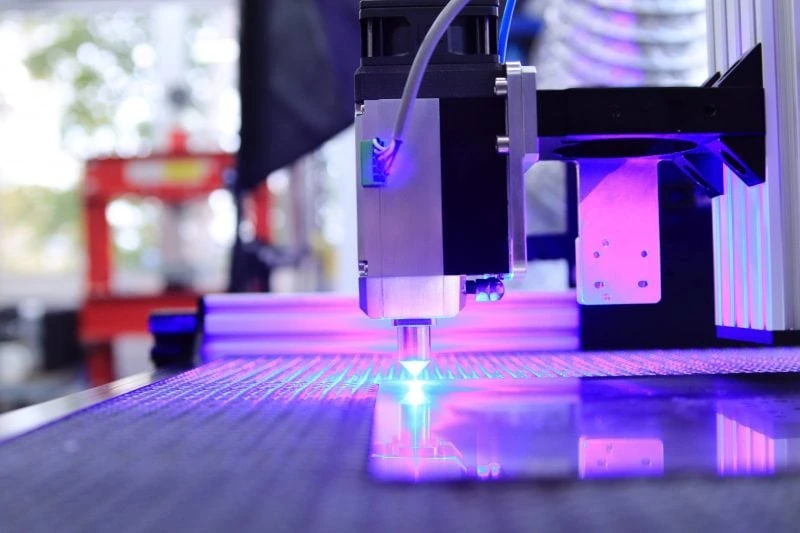

Laser cutting machines use the heat emitted by a laser beam guided by mirrors or optical fibers. Laser cutting allows you to cut different materials without changing tools but instead adjusting the laser parameters. It’s a precise process, allowing for complex contours because of the tiny notch width. The cutting speed varies based on the material to be cut, but they are universally very fast. Lastly, the chance of workplace accidents is also significantly decreased. This is because the laser cutting machines are fully automated and require very little manpower.

Advantages of CNC Laser Cutting

- High cutting accuracy

- High speed

- Good cutting quality

- Low noise level

- Low vibration

Information about Choosing the Right Laser Cutter

Let’s explore some questions to consider when selecting which laser cutting machine is best.

- How many times have we lost business because of late delivery?

- Have we ever had to reject parts because of poor quality?

- How would it help our image if we had our own laser cutting capabilities?

Types of Laser Cutting Machines

Three main types of lasers currently make up most of the industrial market: traditional CO2 gas lasers, Crystal lasers, and newer solid-state fiber lasers. CO2 lasers have been the leading provider to the metal fabricating industry for the last two decades, whereas the fiber laser made its debut around 2008.

1. CO2 Laser Cutting Machines

These lasers are forefront in the foundation of the metal industry. They work by passing electricity through a gas-filled resonator. As a result, this can help you focus and deliver the laser beam by using mirrors.

Materials

- CO2 laser continue to be the preferred material over modern fiber lasers. They are generally used for cutting plastic, foam, wood, glass, or soft steel. The limitations of a CO2 laser include cutting reflective metals such as copper or brass.

- These metals are known as reflective because they can reflect light (laser) back to the machine.

- A CO2 laser cutter has a high risk of damage if it tries to cut these reflective metals.

Easy Maintenance

Some manufacturers are more comfortable using CO2 technology because it’s been around longer. So, the familiarity makes it easier to manage in-house maintenance.

Popularity Holding Steady

CO2 laser cutters are the most common and well-reputed because of their efficiency and lower prices.

2. Crystal Laser

- Crystal laser cutters generate beams from nd:YVO (neodymium-doped yttrium ortho-vanadate) and nd:YAG (neodymium-doped yttrium aluminum garnet)

Variety of Materials

- Crystal laser cutters generate wavelengths smaller than CO2 lasers and can cut through some thicker and stronger materials. Smaller wavelength is also a factor that contributes to better focus and higher intensity.

- Crystal lasers can be used with metals, plastics, and ceramics.

High Maintenance

Due to the high-power functionality, crystal laser parts wear out faster.

Low Popularity

The price point and maintenance cost leave these laser cutters as the least popular option.

3. Fiber Laser Cutting Machines

Operation

- In a fiber laser, banks of diodes are used to create a laser channeled and amplified through a fiber-optic cable.

Materials

- The early models could only cut thin materials at high speeds. However, the new powerful lasers provide cuts in up to 1.5 inches of thick material while maintaining higher cutting speeds than the CO2 laser. In fact, they are three times as efficient compared to CO2 laser cutters.

- Fabricators that require cuts of reflective material, such as brass or copper, can use a fiber laser with ease. A CO2 laser is difficult to use on certain materials, in addition to that. Therefore, fiber lasers are the choice for cutting sheet metal, steel, stainless steel, aluminum, and some plastics.

Challenging maintenance

- Fiber lasers are generally maintenance-free and feature a long service life of at least 25,000 laser hours, therefore displaying a far longer lifecycle.

- This is not to say that fiber lasers are indestructible. There is a chance that they will occasionally need maintenance. You most likely won’t have access to in-house maintenance choices because fiber lasers are a more recent technology. In the event of a problem, you will probably need to contact your supplier.

Growing popularity

- Even though fiber lasers have a higher price tag, they have lower operating costs and have become the popular choice.

Steelway Laser Cutting Guarantees the Best Quality Service

Deciding which laser cutting machine suits you depends on several factors, including choosing the right laser cutter based on product quality, cost performance, and service. This decision will vary depending on your specific laser cutting needs.

Steelway Laser Cutting is here to help you sift through your options to make the most practical and logical decision. However, the answer to which laser machine you should choose is yours to make. After a comprehensive comparison, you can be confident in selecting the right laser cutting machine for your business needs.

Contact us today to achieve the best results for all of your laser cutting projects.