Stainless steel has come a long way since variations of this metal were first developed in the early 19th century. Versatile, cost-effective, and can be used in multiple industries, stainless steel is one of the most common metals used in products of all varieties. This is compared to other materials, and stainless steel use in manufacturing and materials is on the rise.

Amid the COVID-19 crisis, the global market for steel was estimated at 1.7 billion metric tons for the year 2020. Additionally, this is expected to rise to 2.2 billion metric tons by 2026, growing at more than 4% per year.

It’s easy to see why stainless steel is growing in popularity, with higher manufacturing rates year after year and with a lifespan that can reach up to 50 years, combined with an attractive price tag. Stainless steel is often the best option for quality materials that can outlive their counterparts, such as wood or plastic. With a manageable cost and high efficiency compared to other metals and materials, stainless steel can increase power industries across the spectrum as a top-quality material that can achieve a range of uses.

Table of Contents

Laser Cutting Machines for Stainless Steel

What is Laser Cutting?

What is Stainless Steel?

Can You Laser Cut Stainless Steel?

How Laser Cutting Machines Work

Which Laser Machine is Best for Cutting Stainless Steel?

What Are the Advantages of using Laser Cutting Machines to Cut Stainless Steel?

What Industries Benefit the Most from Using Laser Cutting Stainless Steel?

How Can You Use Lasers for your Stainless Steel Sheets and Products?

Partner with Steelway Laser Cutting for Your Stainless Steel Laser Cutting Projects

Stainless Steel & the Cutting Process

Thin metals to stainless steel sheets with a noticeable thickness, and cutting stainless steel is not a one-size-fits-all process for any industry or manufacturing company. In addition, professional assistance and specialized machines are often required to efficiently create pieces of steel and metal with the utmost precision.

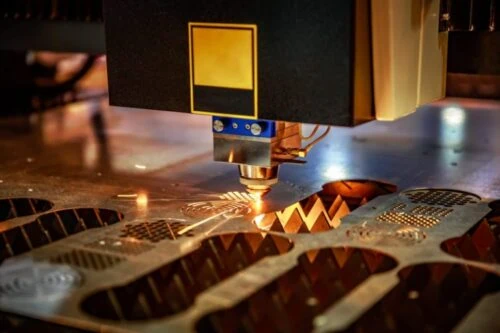

Therefore, when cutting materials like stainless steel, laser cutting machines are at the forefront of the cutting process. Using a finely tuned laser beam, a laser cutting machine can cut sheets of steel at all levels of thickness, and lasers can cut edges to the most minute specifications. This leads to increased productivity for manufacturing companies, and better metal products.

Laser Cutting Machines for Stainless Steel

When it comes to laser cutting and laser cutting machines, what stainless steel grades can be accommodated? What are the operating costs of utilizing laser cuts, the speed of the process, and how can you ensure that the cutting process results in the highest level of quality for your steel materials?

It starts with understanding the laser cutting process. It is important to understand the different types of lasers and laser cutting machines available. This will help you determine the right laser cutting service provider – and cutting method – that will work best for your industry and your company.

What is Laser Cutting?

Laser cutting, first introduced in the 1960s, is a technology that uses a laser beam to cut edges in varying materials. This includes thick and thin metals, such as stainless steel, carbon steel, brass, copper, and virtually every metal used in industrial industries.

At Steelway Laser Cutting, we take this modern laser cutting process a step further by utilizing a CNC laser cutting machine. It is a piece of computer numerical control (CNC) equipment that uses a focused, high-powered laser beam to cut, mark, or engrave various materials, including steel and other types of metals.

What is Stainless Steel?

Stainless steel is an alloy of iron that can be transformed into sheets, plates, bars, wires, and tubing. As a result, this versatility makes stainless steel one of the most popular metals and materials in manufacturing processes across all industries.

Compared to other metals or materials like plastic, acrylics, fabric, or wood, stainless steel tends to have a lower cost, higher quality and is easier to process. This is why stainless steel is found in products and machines everywhere in the world, from appliances to motor vehicles.

Can You Laser Cut Stainless Steel?

Laser cutting machines can tackle metals of all varieties, and this most definitely includes stainless steel. Steel laser cutting involves creating parts by removing material from a solid workpiece or sheet, using a variety of lasers and/or cutting tools. This is the basic process of a CNC laser cutting machine and can essentially be divided up into three distinct steps:

- An engineer designs the CAD (computer-aided design) model of the specific part, which will then feed into the laser cutting machine.

- The operator of the laser cutting machine transforms the CAD design into a computerized program and prepares the machine for the ensuing laser cuts required.

- The laser cutting machine executes the cutting process, removing excess material and creating cut edges to the identified specifications.

Stainless steels are ideal materials for laser cutting machines. Despite their thickness, stainless steel sheets can be easily maneuvered through a laser cutting machine to create desired surfaces, bends, and cut edges. While there are other processes available for cutting stainless steels, laser cutting machines are generally considered the best option for creating parts efficiently and with expert precision.

How Laser Cutting Machines Work

Laser cutting machines effectively use the heat from a laser beam to cut different materials without changing or utilizing different tools to create cut edges. Instead, laser cutting machines simply require an adjustment to the laser’s parameters to indicate changes to the cutting process. For example, adjusting the thickness or allowing for complex contours in the metal or other materials.

The laser is guided by mirrors or optical fibers, with specifications outlined prior to the cutting process. This means there is little human involvement compared to traditional cutting processes for stainless steel and other metals. As a result, laser cutting machines reduce costs and provide better quality, regardless of the eventual use of the cut stainless steel or other materials.

Which Laser Machine is Best for Cutting Stainless Steel?

There are multiple options when it comes to identifying the best laser cutting machine for your specific needs. This includes the operating costs, cutting speed, and overall process which will vary based on your laser source.

So, before you determine the laser cutting machine to utilize for a specific cutting process, it helps to understand the different laser cutting machines and laser types available, and how they address various metals.

Fiber Laser Cutting Machines and Systems

In a fiber laser cutting machine, banks of diodes are used to create a laser that is channeled and amplified through a fiber-optic cable.

Initially, fiber laser cutting machines could only produce laser cuts in thin materials and metals at high speeds. However, modern fiber laser cutters can address stainless steel and other metals up to 1.5 inches thick. Furthermore, it maintains the higher cutting speeds required to complete the laser cuts quickly and efficiently.

As a result, fiber laser machines are generally the laser cutting machine of choice for a wide array of metals, including sheet metal, stainless steel, brass, copper, and even some plastics.

Best of all, fiber laser cutting machines require little long-term maintenance, with a service life of approximately 25,000 fiber laser cutting hours. This means that companies can reduce costs when it comes to downtime compared to other laser cutting machines.

Therefore, fiber laser cutting systems are not indestructible. A highly trained specialist is generally required to address any fiber laser related issues, due to their complicated makeup and use of the most modern fiber laser technology available.

CO2 Laser Cutting Machines

CO2 laser cutting machines are the foundation of the metal cutting industry, and they are powered by passing electricity through a gas-filled resonator. Through this gas-based process, the laser beam is focused by using mirrors to cut metals, stainless steel sheets, and other materials.

Furthermore, CO2 laser cutting machines are typically used for cutting varying materials such as plastic, acrylic, fabric, foam, wood, glass, or soft steel. Therefore, CO2 laser cutting machines have difficulty with reflective metals, such as copper or brass.

CO2 laser cutting machines are some of the most common laser cutting machines and have been around longer compared to fiber laser cutting machines. However, the established technology makes it easier to power and maintain in-house.

Additionally, CO2 laser cutting machines, which use gas and electricity, are more susceptible to damage than fiber laser cutting machines. This may be a factor for the extra costs involved when it comes to maintenance and downtime.

What Are the Advantages of Using a Laser Cutting Machine to Cut Stainless Steel?

While laser cutting machines are the norm in our modern era, they aren’t the only cutting tool available for manufacturing processes. For example, plasma cutting began in the 1950s before laser cutting was launched. Moreover, the plasma cutting process involves a highly concentrated channel of electrically conductive gas that transmits energy from a power source to the metal or material that requires cutting.

However, when determining the best cutting machine or cutting process for your specific manufacturing needs, a laser cutting machine is generally considered the best option to achieve optimal quality and minimal costs.

Here are just a few reasons why laser cutting reigns supreme for cutting surfaces across all materials and metals, compared to other methods.

Better Precision

Laser cutting generates the smallest heat affected zone among all thermal cutting techniques. Therefore, the laser beam melts the stainless steel sheet or other workpieces, into specific shapes and other laser cuts to specifications. The laser head is the source of the laser beam. It is used for all laser motion and position measurements. These specifications can range widely for materials of all thicknesses, resulting in precise cuts that don’t sacrifice speed or quality or result in additional costs.

Speed

One of the main benefits of using fiber laser cutters and other modern laser cutters is speed. Because fiber laser cutters (and other laser cutters) are powered by a motion system that requires no human adjustments throughout the cutting process. Therefore, the laser head adjusts automatically based on the laser cut specifications, and the process can continue uninterrupted, 24/7.

Improved Edge Quality of Material

The quality of a laser cut is unmatched when it comes to cutting stainless steel sheets and other materials, regardless of the original workpiece’s thickness or quality. Because of this, companies can reduce costs on ill-fitting or incorrectly manufactured parts and can rest assured that every piece of material that has been crafted with a laser cutter is of the highest quality.

Programming Available

While a precise laser cut is typically the end game of using a fiber laser cutting machine, it’s not the only process a laser cutting machine can tackle. In fact, some of the most modern lasers can perform additional manufacturing processes, like welding. This helps streamline a range of operations and results in increased productivity for manufacturers across all industries.

Reliability

Laser cutting machines (especially fiber laser cutting machines), are renowned for their reliability as every intricate part of a laser cutter – from the head to the software – requires little maintenance or special services to function. As a result, manufacturers will enjoy a high level of quality for every sheet of metal that needs a laser cut, or other processes. With this process, little to no downtime would result in added delays and, eventually, added costs.

Best of all, manufacturers will enjoy increased productivity without extra effort to power their operations because of the high cutting speeds without interruption.

What Industries Benefit the Most from Using Laser Cutting Stainless Steel?

A range of industries that can benefit from using lasers to perform precision laser cuts in their products and parts. Stainless steel is utilized in a number of sectors around the world, with the construction, automotive, medical, and power industries leading the way.

With that being said, any manufacturing company that utilizes sheets of stainless steel in any capacity, regardless of thickness or required laser cuts or bends, can benefit from lasers to cut materials. Additionally, typically all varieties of metals and materials can be tackled by the laser cutting process.

How Can You Use Lasers for Your Stainless Steel Sheets and Products? It Starts with Steelway Laser Cutting

When finding a powerful resource for laser cutting, companies across all manufacturing industries don’t have to do it alone.

Large companies can purchase a laser cutting machine or check out local advertising for laser cutting services in their area. However, this is typically not an efficient way to incorporate lasers and laser cutting machines into your manufacturing processes.

For one thing, lasers are expensive and need a pristine, clean-air environment to function properly. Therefore, the most modern fiber laser cutters and other laser cutting machines are generally cost-prohibitive for companies to purchase.

Using lasers to melt away materials is the best method for creating cuts in stainless steel. Therefore, the best option for manufacturers of all sizes to utilize lasers in their operations is to partner with an expert in the laser cutting process.

Partner with Steelway Laser Cutting for Your Stainless Steel Laser Cutting Projects

At Steelway Laser Cutting, we can save your company time and money by performing the most precise laser cuts with the best technology available. From our arsenal of the best laser cutting machines available, to our trained engineers who can tackle any laser cut and any project, we can handle projects with high-volume orders of 1000+ units. Also, we can cut sheets of stainless steel and other metals with ease.

Our top-of-the-line machinery gives us the ability to implement any special requirements required for a project. Additionally, our TruLaser 1030 fiber laser cutting machine also optimizes the manufacturing process to make it even more reliable, high-quality, and cost-efficient.

From small stainless steel projects to high-volume and complicated endeavors, Steelway Laser Cutting is your best resource for manufacturing projects of all sizes, with multiple laser cutting options to address your specific requirements.

Let’s start streamlining your manufacturing options, so you can have a more profitable, efficient, and reliable business from the inside out.

Telephone No.(610) 897-0486