Regardless of your industry, if your business utilizes custom metal parts, (or any custom parts such as wood, plastic or acrylic), then chances are, your operations can benefit from custom laser cutting services.

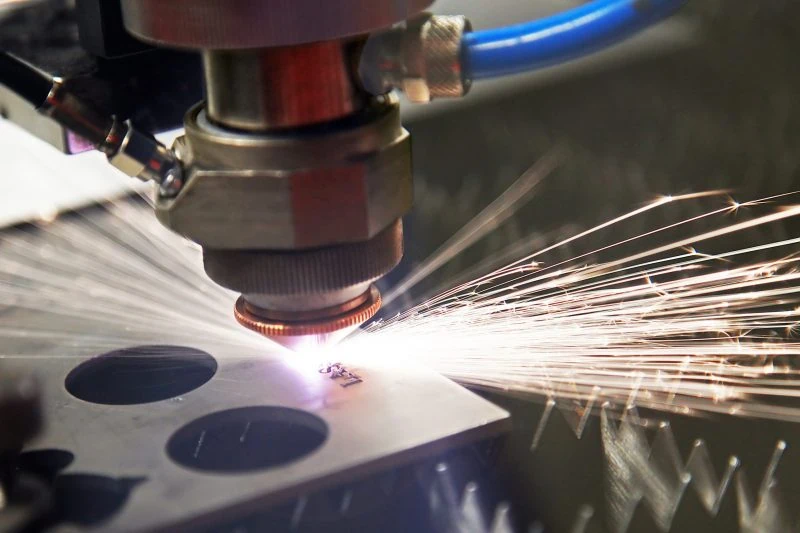

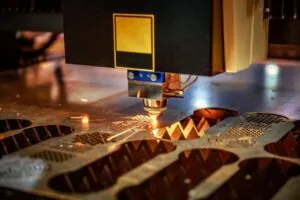

Laser cutting involves using a focused laser beam to create intricate laser cuts on metal parts of all styles and thicknesses. From thicker materials like copper or brass, to more delicate metal parts like mild steel or aluminum. Additionally, a laser cutting machine provides precision cuts that are cost effective and follow specifications to the letter.

Custom laser cutting can be a benefit to any industrial process. However, whether you require custom metal parts for the manufacturing, automotive, medical, or construction industries, the key is to find a quality laser cutting services provider.

Not all laser cutting services are created equal. You want a metal cutting service provider that can produce high precision results at a high speed, regardless of the thickness of the material, the cutting specs involved, or additional needs, like shipping.

Custom Laser Cutting Services with Steelway Laser Cutting

When choosing a metal laser cutting services provider, it’s equally important to examine the laser cutter details, beyond an instant quote or a quick price estimate. The quality of the resulting laser-cut parts will be highly dependent on the laser cutter itself and the machining process. Therefore, you want a laser cutting partner that provides the most modern metal laser cutting services at high speed and project completion rate.

At Steelway Laser Cutting, we have the high-powered laser capabilities to address all metal laser cutting projects, including those that use thick materials like brass and copper.

When it comes to laser cutting services, from waterjet cutting to burr-free cuts, it’s essential to understand the materials, the lasers, and all aspects involved.

Let’s explore the following guidelines for exceptional custom laser cutting.

Table of Contents

How Does Laser Cutting Work?

How Long Has Laser Cutting Been Around?

What Custom Metal Parts and Materials Can be Cut with Laser Cutting Materials?

Which Industries Benefit from Custom Metal Laser Cutting?

Benefits of Custom Metal Cutting with a Laser Cutting Machine

Revolutionize Your Operations with Laser Cutting Services

An Overview of Custom Laser Cutting

What is Laser Cutting?

Laser cutting is used to cut materials like copper, steel, brass, aluminum, and other metals by vaporizing the materials, resulting in a cut edge based on a single prototype or design. The Computer Aided Design software file (or the CAD file) provides the specifications. Furthermore, the laser cutting machine does the rest, resulting in a custom laser-cut metal parts that can be utilized in a finished product for varying industries.

How Does Laser Cutting Work?

The laser cutting machine and CNC machine (computer numerical control) direct the laser beam to the material. A laser beam is generally focused using a high-quality lens in the work zone. The laser cutting machine uses the heat from the laser beam to create custom cuts or contours in varying metals, like copper, steel, brass, or aluminum.

In addition, there is no need to stop the process or adjust the laser to create different cuts. Instead, laser machines use an automated adjustment to the laser beam’s thickness and/or focus on making challenging metal cuts and crafting intricate metal parts of all varieties.

Laser cuts are renowned for their precision since no cutting edge which can become contaminated by the material, (or vice versa.) As such, even the smallest and most complicated but quality parts can be cut at high speed, for industries where custom metal part precision is essential, like the automotive or medical industries.

How Long Has Laser Cutting Been Around?

While modern laser cutting machines are some of the most advanced tools available for crafting custom parts out of stainless steel, aluminum, sheet metals, and other materials of varying thickness, laser cutting has been an established process for over 60 years.

In 1965, the first laser cutting machine, made by the Western Electric Research Center, was used to drill holes in diamond dies. Additionally, in 1967, the British pioneered laser-assisted oxygen jet cutting for metals was invented. In the 1980s, this laser technology expanded and was even used to cut non-metals, like acrylics, plastics, and wood. Therefore, as the decades progressed, the precision and the materials that could be cut with laser cutting machines expanded.

Today, when industry leaders think of laser cutting, they correlate laser-cut parts with metal parts.

Modern laser cutting machines can tackle metals with extremely high levels of thickness (like brass, steel, and copper) in a high energy and high-speed process that utilizes a targeted laser beam. Simply put, laser cutting and metal laser cutting– has come a long way in the past six decades. oday’s laser cutting machines can create custom metal parts at a high cutting speed of all shapes and sizes.

What Custom Metal Parts and Materials Can be Cut with Laser Cutting Machines?

One of the great aspects of modern laser cutting machines is that they can tackle virtually all types of materials to create custom parts.

Common metals and materials that benefit from laser cutting services include the following:

- Aluminum – Generally known as one of the more delicate metals in terms of thickness, aluminum is a perfect metal to undergo a laser cutting process.

- Steel – Steel is one of the most diverse metals in manufacturing industries, and a laser cutting machine can perform precision cuts to steel in all its form. From mild steel with oxidized surfaces, to stainless steel, (which includes coated or uncoated stainless steel), a modern laser cutting machine can tackle all steel types.

- Brass – Though brass has a reputation as one of the more difficult metals to transform into cut metal parts, it is a strong candidate for the laser cutting process, despite its thickness.

- Copper – Like brass, copper can be difficult to cut, but this valuable metal can be easily transformed into custom parts with a laser cutting machine.

- Plastic, Acrylic, Wood and other metals or materials – Arguably, laser cutting machines are best and most utilized for varying metal cuts. However, plastic, acrylic, wood, and other non-metal materials can all benefit from the laser cutting process.

Your laser cutting services provider will be able to provide a better overview of the materials and metals they can tackle, which may include wood, plastic, acrylic, and miles beyond.

Which Industries Benefit from Custom Metal Laser Cutting?

Regardless of how companies need to transform molten materials or sheet metal into intricate parts, laser cutters are an ideal vehicle for creating high quality materials at an attractive price.

Furthermore, when cutting stainless steel, aluminum, other steels, and other metal parts, a few industries can benefit greatly from laser cutters creating of all their high-quality and specially cut parts.

Automotive Industry

The automotive industry relies on various materials to create high-quality cut parts of varying material thickness, which are pieced together for a finished product. From sheet metal that is bent and shaped into the backbone of a vehicle, to small pieces of steel and other metals that are crafted with a laser, there are several advantages to using laser cutting for this metal-reliant industry.

Advantages of using a laser cutter in the automotive industry

Auto manufacturers are one of the largest users of cut parts created by laser cutters, and for good reason. Laser cutters are exceptional for metal cutting and can handle all the metals that make up a complete vehicle, inside and out.

Laser cutters can even handle delicate materials like carbon fiber used to manufacture automobile springs and other custom parts where light weight and high strength is required. Therefore, laser cutters can tackle a lot more than straightforward cutting for materials like carbon fiber, stainless steel, and other steels and metals.

In fact, a laser cutter can create indentations, holes, bends, curves, and other alterations to the material. This can be achieved without any cutting involved – to make perfectly contoured parts that can connect and fit together with the utmost precision.

Best of all, because steel is so prevalent in the automotive industry – and because steel is one of the best materials to work with when it comes to laser cut metals – laser cutting, and the automotive industry seamlessly goes hand in hand.

Construction Industry

The construction industry use a wide array of materials to construct quality homes and structures of all varieties, and for all purposes. Regardless of whether you need metal plates for prefabricated structures or pieces of aluminum for windows, gutters, door frames, and roofs, a laser cutter can transform a piece of sheet metal into the cornerstone of a new home.

Advantages of using a laser cutter in the construction industry

Aluminum is a material that can especially benefit from laser cutters, as this material – (unlike wood or acrylic or stronger metals) – can be difficult to work with. Luckily, lasers can tackle even the most refined cuts in aluminum and other metals, making them adaptable to any cut part required for the construction industry.

Aluminum may be one of the most-used sheet metals in the construction industry. However, laser cutting can provide various services for quality home construction. Even wood and acrylic aspects of home construction can be transformed into laser cut parts. Therefore, while metal cutting is arguably the most popular use for laser cutters, it’s certainly not the only way lasers can be used in this essential industry.

Medical, Manufacturing, and Other Industries

The sky is the limit when it comes to industries that can benefit from metal cutting services. A laser that utilizes electrical conductivity to create a precision cut can be enlisted for any purpose. This includes cutting huge pieces of sheet metal into small components of a larger metal product, to shaping or bending aluminum or stainless steel into ingenious and custom ways.

Remember that the type of laser cutter will play a big role in the effectiveness, price, and quality of your laser cut parts. Many specific lasers that can be involved in metal cutting and other cutting processes, like YAG lasers, fiber lasers, and specifically designed metal lasers.

The best way to identify the most beneficial process for creating laser cut parts, regardless of material thickness, is to start with an online laser cutting consultation. An established laser cutting service provider won’t just give you a price instantly. However, they will also discuss the varying laser cutter options – from fiber lasers to plasma cutting – and will walk you through the process, one step at a time.

Benefits of Custom Metal Cutting with a Laser Cutting Machine

There are many benefits to cutting a plate or piece of sheet metal with a high-quality laser metal cutting machine. Many of these include (but is certainly not limited to) the following:

Precision

In our modern world, manufacturers across all industries need metal parts and other materials (like acrylic) that are cut to absolute precision. As technology advances, so does the need for every metal part to be a perfect fit. Laser cut metals are among the most precise, as a laser cutting machine can produce clean and precise cuts for even the most intricate designs.

Better Reliability

Laser metal cutting is a hand-off process, which means that there is less room for human error or human interaction which can lead to contaminated materials. Instead, detailed instructions are fed to the online laser cutting machine, and a perfect laser-cut metal piece is produced repeatedly, regardless of how many pieces are needed.

Lower Price

Even if shipping is required for the laser-cut metal parts, laser cutting is still a more attractive option when it comes to price. This is because little work or personnel is necessary to start and continue the laser cutting process. All that you need is the sheet metal or metal piece, the design specifications, and the high-quality laser that performs the work.

Less Material Contamination and Waste

Companies also save money in the laser cutting process when it comes to contamination and waste. The faster and more accurately a laser cutting machine can work, the less chance there is of unnecessary exposure and risk of damaging the material. In addition, because these lasers are so precise, the job is done correctly the first time. Therefore, all subsequent times that a cut is necessary, resulting in much less material waste.

Faster Timeframe

Laser cutters can work 24/7, 365 days a year, without interruption. In addition, once the laser cutting process begins, there is no need for technicians or personnel to make any adjustments. As a result, even if metals that need to be cut are outsourced, (and shipping back to the company is required), the timeframe to transform aluminum, stainless steel, and other metals into precise and perfectly cut pieces is significantly reduced.

Improved Flexibility

As mentioned, laser cutters can address any material, from aluminum to stainless steel. Which is why they are one of the most-used methods for cutting metals in all industries. Offering a wide array of services for manufacturers, laser cutting machines are adaptable like no other method for transforming materials.

Note: Laser cutters can even perform additional and detail-oriented tasks, like prepping products for powder coating. If powder coating is necessary after cutting, you can use nitrogen in the cutting process to produce the smoothest finish possible.

Ready to Revolutionize Your Operations with Laser Cutting Services?

It Starts with Steelway Laser Cutting!

You can look for laser cutting partners who provide instant quotes or have a high Google rating score, but your search should begin and end with Steelway Laser Cutting.

Regardless of the sheet metals or materials that serve as the backbone of your industry, we have the most cutting-edge laser cutters available to complete your projects in a timely and efficient manner. We deal with high volume orders of 1,000 units per product, (with or without shipping), and can tackle the most difficult metals to work with, including copper, bronze, aluminum, stainless steel, galvanneal steel, and regular hot rolled steel.

Simply put, combining decades of expertise and the most advanced laser cutting equipment available is what sets us apart.

Reach out to us today, regardless of your industry or laser cutting needs. Let’s start a conversation about how laser cutting can transform how you do business.