CNC cutting and laser cutting methods are used in the manufacturing industry to produce intricate, precise, and reliable parts and components. The method you choose, however, depends on what you would like to accomplish. The difference between a CNC cutter and a laser cutter can be a source of confusion, as each application performs similar functions, but in very different ways.

Our team at Steelway Laser Cutting believes that with a clear understanding of each method, you can confidently choose the technique that meets the manufacturing needs of your industry.

If you need manufactured stainless steel or sheet metal that requires custom metal cutting, then it’s good to understand the difference. Knowing the differences between laser cutting and other services will help you decide which is ideal for your project.

What is CNC Laser Cutting?

Before we can compare the two different processes, we need to ask, “What is CNC Cutting?” CNC stands for Computer Numerical Control. CNC cutting is a method that utilizes computing power and modern technology in order to automate a large number of tasks that traditionally would have been done manually, by either a carpenter or metal worker. A game-changer in the world of computer-aided manufacturing, CNC technologies are now widely used in several different trades.

Similarities Between CNC Cutting and CNC Laser Cutting

Both CNC cutting and CNC laser cutting are fundamentally very similar in the way that they operate their equipment using the same type of computer programming. This is why the CNC abbreviation is used to describe both methods.

Manufacturing industries depend on companies that can work with metal in order to shape, bend, or cut unique designs to make specialized parts. Both CNC cutting and CNC laser cutting machines can be used for these purposes.

CNC machinery offers a greater deal of accuracy compared to a manual approach and it is simple to use in a workshop. Once you’ve created your design file using software such as CorelDRAW or AutoCAD, we simply upload it to the machine, set the power and speed, and press go.

Main Differences between CNC Cutting and Laser Cutting

The Process of CNC Laser Cutting

Tools/Router

- After the design is created it is programmed into the computer, and it sends a signal to the CNC machine. After, the computer interprets the design and uses specialized tools, such as a router, to cut that design into the material of choice. The router moves back and forth, as well as side-to-side along axes while following the shape of the design.

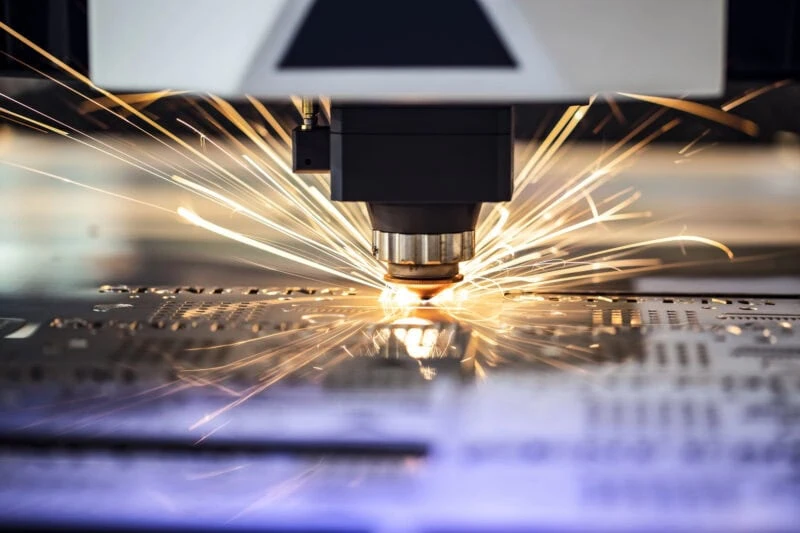

CNC Laser Cutting

- After interpreting the design, the programmed CNC system guides the metal cutting machine, which relies on heat rather than tools to do the custom metal cutting. This high-energy light beam is a laser that burns through the metal material, opposed to the CNC router tool that carves out the design.

Ready, Set, Precision and GO!

CNC laser cutting can repeatedly and consistently produce more complex designs and shapes than regular drills. Which means that more intricate parts to high tolerance with exceptionally smooth finishes.

For example, the width of the cut depends on the width of your cutting tool. The smallest router bit has a radius of about 1mm, while the radius in a laser beam can be 0.1mm. So, because of this, you can cut detailed designs with accuracy. You are guaranteed a much higher degree of precision for even the most intricate of designs.

The Final Product

A CNC laser cutter offers a better finish to materials due to its use of heat rather than friction. The heat burns the edges, which not only keeps them clean, but also seals them and improves the overall finish and appearance. In fact, the high-quality cuts produce such smooth-edged finishes that it does not require further cleaning, treatment, or anything else.

Choose CNC Laser Cutting for All Your Metal Cutting Needs

No matter what type of metal you are working with, you can choose any of the techniques to get your job done efficiently. From the information mentioned above, you can consider how CNC cutting and CNC laser cutting are different and which one can be the best and most optimal solution for your project. Your needs will be met by machines, laser cutting capabilities, and applications that are available.

CNC Laser Cutting Services with Steelway Laser Cutting

At the end of the day, the benefits of CNC laser cutting are the reason big companies use laser cutting technology, and it remains the first pick among globally renowned industries. Steelway Laser Cutting recognizes this demand by offering industrial CNC laser cutting services. Our extensive services are sure to meet your manufacturing needs.

Contact us today to get a complimentary quote on your next project.

Article reviewed and approved by Director of Product Design – Derek McAvoy.