Large manufacturers, small businesses, and artists rely on engraving processes to transform metal parts and products. From crafting intricate and artistic designs to stamping permanent serial numbers or branding elements, the ability to create precise engravings on metal materials is a necessity across multiple industries.

Therefore, metal laser engraving is the best option when it comes to ensuring the utmost accuracy, precision, and attention to detail. If you are seeking unparalleled craftmanship and laser engraving in Pennsylvania and beyond, Steelway Laser Cutting is your ultimate partner.

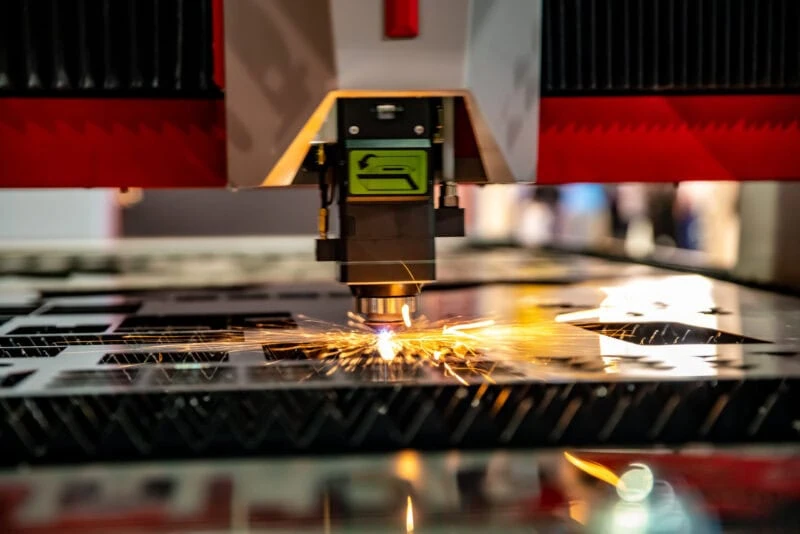

Laser engraving on metal is a streamlined and automated process, especially when the best laser engraver is available. Whether you opt for a fiber laser engraver, CO2 laser engraver, or diode laser engraver, the advanced laser technology behind the scenes that is powering the operations will bring all engraving designs to vivid life.

How Laser Engravers Achieve High Precision

The primary reason why laser engraving is so powerful – and so accurate – is because of the source.

In the laser engraving process, the intensity of the laser beam effectively vaporizes the metal surface. This process is known as sublimation, as the targeted area transforms directly from solid to gas. Unlike older, traditional engraving processes, this ensures that there is no waste material during the process. The laser’s intensity and minute diameter mean that even the tiniest, lightest engravings can be achieved.

The process is further advanced by the technology guiding the work from start to finish. With computer numerical control (CNC) following a software-drafted design, the laser engraving process can be easily repeated with no human intervention and subsequently, no possibility of human error.

The Benefits of Laser Engraving

The laser engraving process results in many benefits that are enjoyed by manufacturers, businesses, artists, craftsmen, and any maker who needs to leave a permanent mark. A sample of these benefits includes the following.

Higher production speed and turnaround time

Since the power drives the laser engraving machine, laser engravers can work quickly and complete intricate engravings in a minimal amount of time. In addition, laser engraving machines can replicate the same design again and again, for as many units as needed. As such, laser engraving is the preferred process for a range of large manufacturing companies that need to create the same engraving on every metal part of a product – like automobile manufacturers, appliance manufacturers, construction and building companies, and more.

Versatility

Not all traditional engraving machines can work with varying types of metal, especially more challenging metals like brass, copper, or gold, or more delicate metals like aluminum. However, laser engraving machines are well known for their versatility. Laser engraving aluminum, stainless steel, silver, gold, titanium, brass, copper, and more tricky materials are easily achievable, in addition to non-metal materials like wood or leather.

Accuracy and precision

Another hallmark of laser engraving is the ability to achieve the best results possible, which is especially essential for detailed designs, and mass-produced engravings that need consistency.

With laser engraving, the results are an exact duplicate of the original design, with no missteps due to human operation or issues with the cutting head and the material. Because of this, companies that require absolute perfection in their engraved marks – such as serial numbers, logos, and other details that must be perfectly correct – can rely on laser engravers to get the job done to exact specifications every time.

Durability and longevity

Laser engravings are also durable and last for the lifespan of the metal part and product. The engravings can be as deep or delicate as required, and laser engraving machines can also produce other types of designs by etching or marking the metal material.

Creative freedom

One of the most significant assets for artists and designers when it comes to laser engraving is the freedom to create any imaginative design, regardless of how detailed or intricate. Traditional laser engravers often do not have the flexibility to make tiny and complex engravings, and the width and depth of the engraving may be unchanging and set in stone with these older machines.

This is not the case with laser engraving machines. Laser engravers, businesses, and artists can create any design, no matter how detailed. As such, it’s a popular and well-used process by designers and craftsmen who want their products to stand out in a crowd because of their inherent aesthetic value and beauty.

Environmentally friendly

Laser engraving is also one of the most environmentally friendly metal fabrication processes on the planet, simply because it reduces waste and requires minimal power to drive the machine.

Cost-effective

Many companies are surprised to learn that using the best laser technology in the industry does not significantly impact their bottom line. In fact, despite being the most advanced engraving process possible, laser engraving is very cost-effective. Additionally, companies save even more by reducing waste throughout the process and by saving time in production runs.

Partner with an Expert to Enjoy the Benefits of Laser Engraving

You can search online for “laser engraving near me,” and you’ll likely be overwhelmed with results. However, to achieve the best results for small artistic laser cut projects or large mass production of metal parts, your best path forward is to work with an expert.

At Steelway Laser Cutting, we have decades of experience bringing the most intricate engravings to life, and we can work with virtually all types of metal materials, all types of designs and all volumes of orders.

With experienced technicians, a state-of-the-art facility, and the best laser machines available, companies can have access to the most precise metal fabrication processes in the industry, while staying well within budget, and on schedule.

Reach out to us today. Let’s discuss more about what you want to achieve, and we’ll strategize a plan on how you can reach these goals when you have ready access to the best laser technology in the business. With an expert resource like Steelway Laser Cutting as your continual partner, the sky is the limit when it comes to making any metal engraving project a perfect success.