Across all industries, laser cutting is becoming the preferred method for transforming laser cut metal sheets into the parts and products we require and use every day. In fact, the global laser cutting market is expected to grow roughly to $6.72 billion by 2024 and $10.35 billion by 2030. Considering how many new sectors and companies embrace this innovative and cost-effective technology, this may be a conservative estimate.

As more businesses have access to the best laser cutting machines on the market, innovative new uses for laser cutting are starting to be introduced to the world. With the help of an expert steel cutting services provider like Steelway Laser Cutting, there’s no limit to the designs and innovations that companies of all sizes can create. The types of fabrication possible when it comes to laser cutting are virtually limitless.

So, what are the possibilities when it comes to laser cut metal sheets, and what does the future hold for these technological advancements in laser cutting services? The answers begin with understanding how metal sheets can be cut, shaped, and reconstructed into a world of new purposes with the assistance of an expert laser cutting services partner.

How Does the Laser Cutting Process Work?

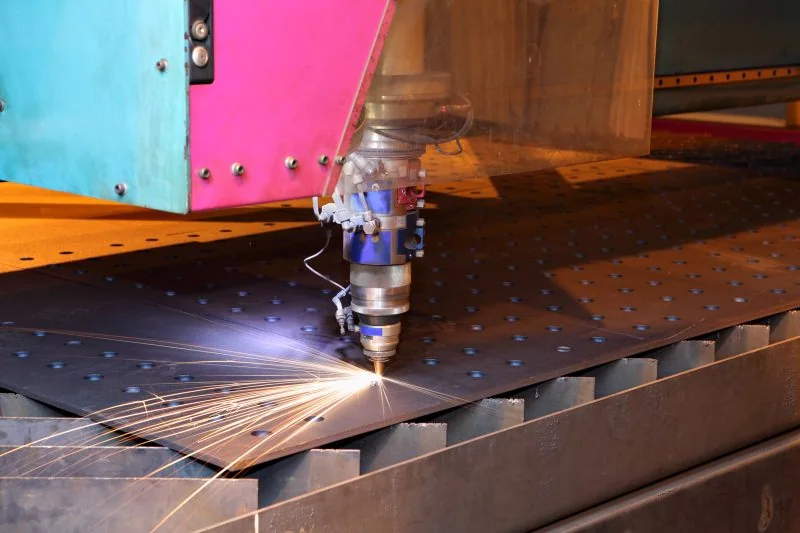

Laser cutting is primarily a hands-off process, unlike older, traditional cutting methods. In its simplest terms, computer-generated guidelines for a desired shape or design are fed into the laser cutting machine. Then, it spells out the exact specifications for how the metal sheet should be cut, engraved, or otherwise altered.

Once the laser cutting machine has these blueprints, the high-powered laser beam vaporizes the raw sheet metal material to unveil the ensuing design without excess waste. The process requires certified laser operators. However, other than having experts on hand to oversee the process, there is little to no human involvement once the process begins. As such, the cutting or design process can be repeated for mass production of thousands of parts or products without interruption or errors along the way.

Why is Laser Cutting Superior to Traditional Cutting Methods?

There are many reasons why laser cutting is more efficient and cost-effective. The process requires limited energy, personnel, and excess labor, and every production run can be completed in a minimal amount of time.

When it comes to innovation, however, the most significant benefit is the sheer versatility of what laser cutting machines can accomplish. Laser cutting machines can perform the most intricate and minute cuts possible. They can also work with a wide range of materials, which opens the floodgates to new possibilities when it comes to better design and better technology.

How is Laser Cutting Changing the Future of Design?

Laser cutting is changing the functionality, longevity, and aesthetic appeal of countless products that are a part of everyday life. Examples of the industries benefiting from the innovation that laser cutting can provide include the following.

Construction Industry

Laser cutting is an effective and cost-effective way to allow architects and construction companies to utilize new materials to design homes, buildings, and other structures. Instead of relying on a base of concrete, laser cutting allows construction industry professionals to use steel as a raw material. Laser cutting can help create buildings with a lighter structure and a more modern and distinct design.

As a result, architects have greater freedom when it comes to styles and shapes, as steel is more versatile than reinforced concrete, but the ensuing buildings and structures are more solidly built as well. By using laser cut steel in designs, structures are automatically more resistant to potential disaster events. These disasters include high winds from hurricanes or earthquakes, making them safer and sturdier across the board.

Consumer Electronics and Medical Gadgets

Since a laser beam can create the tiniest cut possible, it’s becoming instrumental in manufacturing smaller parts and products, especially electronics.

Essential medical devices such as stents and pacemakers, as well as everyday cell phones, can benefit from laser cutting. This technique streamlines the manufacturing of electronics, making it faster, cheaper, and much easier. As a result, costs can be cut for all electronics while technological advancements soar. This helps to create better products and parts that can be mass-produced on a large scale.

Décor and Design

From hobbyists and artists to home décor and furnishing companies, laser cutting allows intricate and inventive designs to come to fruition.

With laser cutting, ornate parts and products of all varieties can be made, from decorative fixtures in the home to unique artwork that can either be one-of-a-kind or mass produced. As such, the home décor and design markets have never been more creative or imaginative, as any new design, no matter how detailed, can be replicated with ease with the assistance of a top-notch laser cutting machine.

How Can I Find Sheet Metal Cutting Services Near Me?

Businesses that want to expand their operations while minimizing costs can certainly do an online search for “metal cutting near me” and be flooded with options. As the demand for laser cutting services grows, so does the number of machines available for sale, and the number of providers that can assist with certain projects.

However, companies that want to utilize the best laser cutting services will want to start with a laser cutting services provider with the most experience and expertise. This is where Steelway Laser Cutting leads the way.

The Future of Laser Cutting Design is with Steelway Laser Cutting

We have been providing laser cutting services for decades. We are always adapting and evolving as technology advances in order to provide our partners with the best possible quality and service for every project.

From large production runs of 1,000 units or more at a time to smaller projects and consultations on how laser cutting can revolutionize your business, Steelway Laser Cutting is your best resource when it comes to maximizing the inherent benefits of laser cutting.

Reach out to our team of experts today to start the conversation. Let’s discuss more about your ambitions and how you want your business to grow while minimizing manufacturing expenses. With Steelway Laser Cutting as your guide, the sky is the limit when it comes to innovative new ways to benefit your business and manufacturing goals.