When most manufacturing professionals think of top-quality laser machines, like a fiber laser or C02 laser, they consider the main advantage of this laser power to be primarily laser cutting metal. Authentic fiber laser machines, C02 laser machines, and other competitive machines can easily use laser technology for metal cutting. However, there are also options for engraving applications.

The laser engraving process varies based on the type of laser machine, the various materials being cut, the engraving area, how much power the laser engraver inherently has, and a wide range of other factors. Certainly, DIY projects for individuals or small businesses can use a simple laser engraver for metal and other materials. However, for industrial applications and the best metal laser engraving results possible, you’ll want to partner with a laser engraver services provider with full access to the best laser engraving machines available.

Therefore, regardless of what specific type of laser metal engraver is doing the job, whether it is a fiber laser engraver, diode laser engraver, or a less expensive laser engraving machine, there are some fundamentals to know about how to laser engrave metal, wood, plastics, and other materials.

Table of Contents

Types of Laser Engraving

Fiber Laser Engravers

CO2 Laser Machines

Diode Laser Engravers

Factors that Will Affect the Quality of Laser Engraving

Laser Engraver for Metal with the Experts at Steelway

What is Laser Engraving?

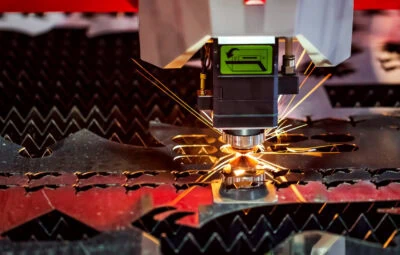

Laser engraving is like laser metal cutting in that the power of a laser beam conducts the metal engraving.

Depending on the precise laser machine, this laser source can engrave metals and other materials of all varieties, as the laser beam vaporizes the sheet metal, leaving behind the designated metal marking. Because of the power of the laser system or laser engraver, there is no excess debris, jagged edges, or errors in laser engraving applications. Additionally, the laser source can replicate the laser engraving process as many times as needed for perfect and error-free metal engraving time after time.

The key to success, and for exceptional results time after time, is to have a top-quality laser engraver or laser engraver machine (like a fiber laser machine). They can handle multiple types of material as needed, as well as a metal laser engraving operator that understands laser engraving inside and out.

From the laser head to the laser parameters to the metal laser marking, several precise steps that must be followed for the best laser engraving results. As such, enlisting professional laser engraving services is often a cost-effective and more productive solution for a manufacturer, small business, or even an artist to achieve the best laser engraver performance possible.

Types of Laser Engravers

There are several laser engraving machine options, and the best laser engraver for your projects or manufacturing production runs can vary. For example, there’s a big difference between etching a one-of-a-kind piece of art and adding serial numbers to thousands of parts, so the exact type of laser engraver you’ll need for your operations is distinctive to your engraving needs.

Fiber laser engraving machines are considered the best option for laser engraving. However, C02 machines, diode laser engravers, and other less-expensive laser engravers can also be used, depending on the metal materials and scope of the laser engraving project.

Here is a closer look at the best laser engravers for metal engraving and other laser engraving projects to help you determine the right laser engraver for you and your business.

Fiber Laser Engravers

Fiber laser machines are considered the best laser engravers for metal engraving because of their precision, high speed, and efficiency. The fiber laser source is doped with ytterbium (Yb), allowing the laser beam to generate a wavelength of approximately 1,064 nm. This creates a good reaction with all kinds of metals. As a result, a fiber laser engraver can effectively engrave metals of all varieties, including aluminum, stainless steel, copper, anodized aluminum, carbon steel, and much more.

Fiber lasers are also distinctive in the laser engraver world because a fiber laser engraver can adapt to different metal engraving or metal marking needs, which include the following:

Laser Engraving with Fiber Laser Engravers

Fiber lasers can create deep and durable metal markings by vaporizing material layers from the metal surface. The resulting metal marks from the fiber laser can stand up to any post-production treatments, like power coating, as well as abrasions or normal wear and tear. When it comes to fiber lasers, engraving is often the most-used application of a fiber laser engraver, and it’s a process that not all laser machines can consistently achieve effectively. (See C02 laser machines below.)

Laser Etching with Fiber Laser Engravers

A fiber laser engraver can also be utilized for fiber laser etching. In this process, the fiber laser engraver creates high-contrast black and white metal markings at a high rate of speed. Different colors or shades can be created in the fiber laser etching process by modifying the metal surface microstructure. In essence, fiber lasers can create these more subtle marks required for very intricate designs, which are just as durable as fiber laser engravings.

Laser Annealing with Fiber Laser Engravers

Fiber lasers can also generate black marks under the metal surface, which preserves the main properties of the metal, such as inherent strength or resistance to corrosion. A fiber laser accomplishes this task by slowly heating iron-based metals (like mild steel or stainless steel) with the laser head or laser beam. Once the steel or other metal is heated, oxygen is diffused under the material surface, resulting in internal oxidation.

All three of the above processes can be tackled with a fiber laser engraver by adjusting the fiber laser parameters and configurations to conduct metal markings as needed.

This makes a fiber laser engraver a highly versatile laser engraving machine. This is because a fiber laser can tackle laser engraving, laser etching, and laser annealing projects with little effort. Best of all, a fiber laser can work with different types of metal. This is especially common for laser engraving aluminum, copper, stainless steel, and other metals or other materials, such as rubber or plastics.

The primary drawback of a fiber laser engraver is the cost. Fiber lasers are among the most expensive laser engraving machines on the market, and fiber laser engravers that are best suited for industrial applications can range from $5,000 to $25,000 or much more, especially if there are additional features like computer numerical controls.

As such, although a fiber engraver has the best features and high power required for laser engraving, it’s often more cost-effective to partner with a laser engraving resource to save on the initial cost of the laser engraving machine, as well as the continual maintenance costs that accompany this expensive piece of equipment.

CO2 Laser Machines

CO2 laser machines are not ideal for engraving metal, unlike their fiber laser engraver counterparts. This is because the wavelength of a C02 laser machine (approximately 10.6 µm) is not readily absorbed by the metal’s surface. So, while C02 laser machines are unsuited for straightforward metal engraving, they can be used to create metal markings using one of two different methods:

- Removing a metal’s coating – C02 lasers can essentially engrave coated metal products by removing or vaporizing the coating with the laser head, exposing the bare metal underneath.

- Bonding – C02 lasers can also use a marking spray to engrave metals. This spray bonds to the surface of a metal, like stainless steel or aluminum, through a chemical reaction with the laser beam. The end result is a clear black metal marking. However, the spray that is not bonded will require the metal surface to be removed from the material manually.

It should be noted that C02 laser machines are not the best option for laser engraving metal specifically. Additionally, they can be used to engrave non-metallic materials and surfaces like plastics, wood, leather, acrylic, and vinyl.

Diode Laser Engravers

Diode laser engraves can be used to engrave metals if the engraving needs are basic and can be conducted without high power or high speed. These entry-level laser systems or laser engravers are less expensive than other laser engravers. However, diode lasers have a lower engraving speed and a lower laser beam quality. As such, they may not be suited for the mass production of parts or products.

Diode lasers come in various wavelengths, which are determined by the energy bandgap of the semiconductor material. The ideal wavelength of a diode laser engraver to engrave metal materials is 1,064 nm, and the laser engraving processes they can perform at this wavelength include the following:

- Direct marking – the best diode laser engravers can engrave metal surfaces like fiber laser engraving machines. However, the engravings aren’t as good or as quickly achieved due to the diode laser’s lower power and lower precision.

- Bonding – like C02 machines, diode lasers can use a marking spray to create black metal markings. In addition, this is an option for less powerful diode laser engraving machines with wavelengths of 400-500 nm.

Keep in mind that while a diode laser engraving machine can tackle some metal surfaces, it may not be the best laser engraver for all metals and materials. This is primarily dependent on the varying features of the diode metal laser engraver, in addition to the metal engraving power and speed of the laser engraving machine.

Factors That Will Affect the Quality of Laser Engraving

There are several factors that will have an impact on laser metal engraver machines to produce quality metal marking and engravings. The cost and power of the metal engraver certainly play a role, and the type of metal laser engraver (like a fiber metal laser engraver as opposed to a C02 laser machine) is crucial.

But additional factors, besides the quality and type of the metal laser engraver, include the following.

The Type of Metal or Material to Engrave

The ability to laser engrave highly depends on the type of metal. The process to engrave copper, stainless steel, aluminum, and other metals can vary, and it’s best to have a metal laser engraver that can effectively engrave a wide range of varying materials, especially if you expect to conduct different engraving projects.

The Surface of the Material

Generally speaking, a metal laser engraver works best with a smooth surface, like a sheet of stainless steel, but understandably that some laser engraving projects occasionally need to include curved products or objects, like bottles or pens. In this case, you can engrave with a rotary attachment. A rotary attachment enables lasers to engrave a surface while the object rotates. Without a rotary attachment, it’s difficult for any kind of laser to engrave any material without a smooth surface.

The Size of the Laser Engraving Area

The size of the laser engraving area also plays a role in metal laser engraving, and the best metal laser engravers can handle large work areas as the lasers are directed via a gantry system or a mounted robotic arm.

Additional Components

Some of the best lasers function perfectly at a high rate of speed simply because they include top internal features like automated doors, rotary tables, and robot compatibility. These lasers are ideal for big production lines and are designed to mass-produce engravings, like serial numbers on car parts or serial numbers or instructions for electronics and appliances.

The Metal Marking or Design

Obviously, the intricacy of the metal marking or design will dictate how easy it is to engrave a metal or other material, and to laser engrave more delicate or complex designs, a top-quality laser machine is all but required.

Quality Control and Expertise of the Laser Operators

Keep in mind that you can have a top-quality metal laser engraver with all the best features in the world. However, your results will nevertheless be dictated by the expertise of your laser engraver operator. It’s best to have extensive training and experience if you plan to tackle more than small DIY projects or one-of-a-kind artistic endeavors.

Automation Capabilities

The ability to automate and replicate metal markings or engravings again and again is commonly found in the best laser machines. These top-quality laser engraver machines use computer numerical control (CNC) and computer-aided design software to feed instructions to the laser head, replicating the design repeatedly to the exact specifications. If you need to mass-produce engravings and want no deviations from one engraving to the next, then you need computerized automation in your laser system.

Your End Game

Do you want to imprint serial numbers on thousands of metal parts or simply add engravings to trophies, promotional materials, or other products? Your laser engraving needs – from metal cut signs to intricate designs – will dictate the quality, and selection of your metal fabrication partner.

Laser Engraver for Metal with the Experts at Steelway Laser Cutting

Steelway laser cutting is known for much more than fast and efficient metal cutting services. We can perform a wide range of metal fabrication processes, which includes metal engraving and etching, as well as engraving services for virtually all types of materials.

Discover how much you can accomplish – and how quickly and efficiently – when you outsource your metal fabrication needs, including metal cutting and metal engraving.

With an experienced partner like Steelway Laser Cutting at your side, your laser cutting and engraving operations can be simplified, more cost effective, and more precise. Our partnership allows your small business or manufacturing company the freedom to expand your designs, your products, and your revenue streams.