Laser cutting technologies have been around for roughly seven decades. However, the advantages of laser cutting have never been more evident as the types of lasers and laser power driving the process continue to improve.

Compared to traditional material cutting methods in the metal cutting industry, laser cutting techniques and technology are by far the most efficient and fastest way to conduct any industrial cutting process with perfect precision.

The key to benefiting from the power of advanced laser technology is having access to the best laser cutting machines in the industrial laser cutting industry. Unfortunately, this is not achievable for most small and mid-sized companies to accomplish in-house.

The best high-power laser cutting equipment is cost prohibitive. These advanced laser cutting machines require intricate knowledge, specialized facilities, and highly specialized laser technicians for the laser cutting machines to perform at their peak.

This is why many companies that require laser cutting for a range of thicker and thinner materials partner with a laser cutting services provider.

Table of Contents

Basic Explanationof the Laser Cutting Process

How the Laser Cutting Process Delivers Precision and Power

Types and Techniques of Laser Cutting

How CO2 Lasers Work

What Type of Materials Can Be Cut with a Laser?

Connect with Steelway Laser Cutting

Laser Cutting Technologies with a Top Provider

Laser processing experts like Steelway Laser Cutting have inherent access to the best laser technology available and ample experience cutting different materials to exact specifications. These variations include thicker materials like stainless steel or carbon steel and more problematic metals like thin and highly reflective aluminum.

Before partnering with a laser cutting expert like Steelway Laser Cutting, it is helpful to understand laser cutting procedures and how evolving laser technology is revolutionizing the various parts and products that can be cut when a laser powers the process.

From artful designs that are one-of-a-kind to mass-produced products that require intricate and perfectly executed cuts like electronics or medical devices, here is how laser technologies shape the cutting process every step of the way.

Basic Explanation of the Laser Cutting Process

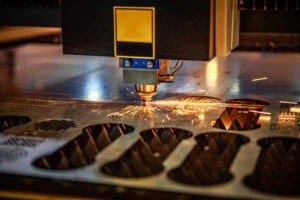

In the simplest definition, laser cutting is a fabrication method that uses the heat of a laser beam to vaporize metal and other materials, resulting in the desired cuts.

Laser Cutting Through Time: A Fast-paced Journey of Innovation!

Laser cutting technology has been in use since the 1960s, initially serving specialized applications within the aerospace industry. However, it has grown in popularity and power in the decades since.

In the 1980s and 1990s, CO2 lasers began to be used on a broader scale in manufacturing operations. They could cut sheet metal efficiently and quickly, with fewer errors or imperfections than metal-on-metal cutting methods.

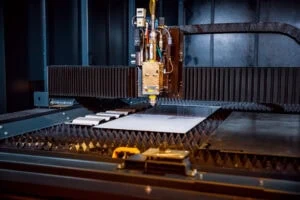

As of the 21st Century, new laser technologies and laser cutting machines have been introduced. These laser cutting machines include fiber lasers and plasma cutting machines, as laser energy and laser power have simply grown.

Today, the machines used in laser cutting are miles ahead of their predecessors. Furthermore, modern laser cutting machines cut metal and other materials with remarkable speed, precision, and intricacy.

How The laser Cutting Process Delivers Precision and Power

Though the exact laser cutting process can vary based on the laser cutting machine, the method for cutting metal with the heat of a laser beam generally entails the following steps.

- The sheet metal or other material is generally held in place, so the cutting surface does not move or shift during the laser cutting process.

- The high energy laser beam is focused onto the sheet metal to make the ensuing cuts. Therefore, laser cutting works by directing a very small diameter and high energy laser beam vertically onto the sheet metal, as the laser head moves the laser beam in X and Y directions, as specified by the laser cutting design.

- As the laser beam contacts the material surface, the metal vaporizes due to the extreme heat of the laser beam. This means that there are no jagged edges, burs, imperfections, or material waste, as the vaporization cutting removes any debris.

- An assist gas is often used in case small amounts of molten material are encountered during the laser cutting process, which can occur in thicker materials like stainless steel.

- Depending on the different materials being cut, and the laser cutting machine itself, different settings may need to be adjusted along the way to make the ensuing metal cuts. For example, the position of the laser cutting head, the diameter of the laser beam, the optimal cutting speed, and the laser power all play a role in ensuring a smooth laser cutting process.

How Computer Numerical Control Plays a Role in Laser Cutting

Regardless of the various types of lasers being used (like CO2 lasers or fiber lasers), the laser cutting process is powered by computer numerical control.

Computer numerical control (or simply CNC) refers to the technology that directs the cutting head and laser light onto the sheet metal surface. In addition, it dictates all the mechanics of sheet metal cutting, from the focal point to the laser-generator power, and the diameter of the laser beam.

Computer-aided design (CAD) software creates these instructions, mapping out all design details for the laser cutting machine. Once the design is fed to the laser cutting machine, the computer numerical control follows the instructions to the letter.

It also follows the pattern and specifications again and again until all units in a production run are complete.

Your laser cutting service provider can assist you with transforming your design into detailed laser cutting instructions that laser machines can effortlessly follow.

However, here are a few tips for creating a technology and software-based design.

- Ensure the design file type works with the most common and advanced types of lasers cutting machines. Optimally, a “Cut Ready” DXF file is best.

- Make sure the design is highly detailed, and all dimensions are to scale.

- Remove any extra instructions or notes that are not part of the design

- Ensure that all lines, loops, and shapes are connected. If there are gaps in the lines in the design, the laser cutting head will pause during the laser cutting process.

Types and Techniques of Laser Cutting

While there are many different and modern technologies for metal fabrication (like plasma cutting), the two most common types of advanced laser cutting machines are CO2 lasers and fiber lasers.

CO2 Lasers

CO2 lasers have been around for decades. However, the newest CO2 lasers are highly advanced. They are a type of gas laser that produces laser light by stimulating carbon dioxide with a mixture of varying gases, such as nitrogen and helium.

The laser cutting process begins when the cutting head directs the laser beam onto the material’s surface, generating heat. CO2 lasers also perform engraving, etching, and marking.

How CO2 Lasers Work

- The gas mixture – The primary gas is contained in a tube, and the combination of gases generates a laser light when it is excited by high–power or high voltage electricity.

- Stimulated emission – These excited gas particles release photons of light, which starts a chain reaction that amplifies the laser beam as it reflects between mirrors also located within the tube.

- Focusing the lens – A series of mirrors direct the laser beam. The cutting head then focuses it onto the surface material at a precise, predetermined spot.

- Cutting process – The laser beam heats the materials, causing it to vaporize or melt. This process creates precise engravings or cuts.

Fiber Lasers

Fiber laser machines conduct a similar process, but these laser cutters generate a highly focused laser beam by sending light from a laser diode through a fiber optic cable.

Therefore, fiber lasers use power to operate efficiently. They can cut both thin and thick materials, including metals like mild steel and stainless steel, as well as non-metals.

How Fiber Lasers Work

- Pump diode – The process starts with a laser diode that emits light, which acts as the foundation or pump to stimulate the ensuing laser action within the fiber optic cable

- A doped fiber – The optical fiber is doped with rare earth elements such as ytterbium. This allows the optical fiber to absorb the pump light and amplify it via a process known as stimulated emission.

- Amplifying the light- As the pump light travels through the optical fiber, the doped atoms are excited and release photos at the same wavelength, amplifying the intensity of the laser light.

- Focusing the lens – This amplified and ensuing laser beam is then directed through a focusing lens and into the cutting head to concentrate the light onto a focal point of the material.

- Cutting process – Just like a CO2 laser, once the laser beam hits the surface material, the intense heat causes the metal or other material to vaporize, leaving behind no jagged or rough edges or excess waste or debris.

Remember that there are many different types of laser cutters that fall into the CO2 laser and fiber laser cutting machine categories, as well as other technologies – like CNC or a motion control system – that guide the process.

In order to enjoy the most precise and efficient benefits of laser cutters, you need to make sure you are working with the most advanced types of lasers and machines available.

What Types of Materials Can Be Cut with a Laser?

Laser cutters can fabricate a wide range of materials.

However, the following are a sample of the most common metals and materials that work well with laser cutters.

- Stainless steel

- Coated stainless steel

- Mild steel

- Carbon steel

- Copper

- Brass

- Aluminum

- Leather

- Glass

- Textiles

Ensuring Precision and Efficiency in Challenging Laser Cutting Projects

If your laser cutting project involves a challenging material, such as thick stainless steel or reflective aluminum, it’s important to plan carefully. Discussing your needs with your laser cutting service provider ensures the best approach for precision and efficiency. What are the benefits of laser cutting for manufacturing and other operations? When the most cutting-edge laser technologies are utilized, companies of all sizes can access a long list of benefits.

A few advantages of laser cutting for metal fabrication projects include the following.

Accuracy and precision

Laser cutters can create highly detailed designs with a laser beam diameter that is as small as .02 inches.

Minimized material waste

This precision allows manufacturers to maximize sheet metal usage without waste. Each part remains consistent, with no deviations or errors. The CNC-driven laser cutter eliminates mistakes caused by imprecise cuts or human miscalculations.

Speed

Laser cutters can cut sheet metal at high speeds, boosting productivity. Even with shipping to and from a laser cutting service, efficiency remains high.

Scalability

Laser cutters can handle projects of all sizes, from small batches of intricately cut metal products like yard décor or artworks to large manufacturing production runs of 1,000 units or more, such as in the automotive or construction industries.

Versatility

Laser cutters can also work with all types of materials, including a range of metals of varying thickness, and non-metal materials like plastic, wood, acrylic, and more.

Cost-effective

With minimal waste, low power costs, higher precision, and faster processing speeds, laser cutters are inherently more cost-effective than traditional cutting machines.

Connect with Steelway Laser Cutting for Advanced Laser Cutting Technologies

At Steelway Laser Cutting, we have the most advanced and innovative laser cutters available, coupled with experienced technicians and state-of-the-art facilities to ensure every laser cutting project, regardless of scale, is a success.

Reach out to us today to tell us about your laser cutting needs.

Let’s start a conversation about how we can use our high-power laser cutting technologies and expertise to benefit your innovation.

From innovative new products to streamlined operations that eliminate errors and waste, Steelway Laser Cutting is the best resource for making metal cutting projects of all varieties come to vivid life.

Ready to partner with an expert in laser cutting in Pennsylvania?

Contact us today for precision quality and innovation!