When it comes to cutting sheet metal and other various materials in industrial cutting operations, there is no cutting process that is as efficient and powerful as the laser cutting process.

Laser cutters or laser cutting machines are the preferred equipment for metals and materials of all varieties. This includes everything from carbon steel and stainless steel to thicker materials like brass, copper, and even plastics and wood. Adopted by manufacturers across all industries, the laser cutting process provides perfectly cut materials and parts with every production run, especially when the most advanced laser cutters are used in the process.

However, what are the fundamentals of the laser cutting process, and how can businesses use the industry’s most advanced laser systems and cutting tools to streamline their operations? How do these high-power lasers work? What different materials can be effectively cut and shaped when a top-notch laser cutting machine is performing the heavy lifting?

Uncovering the answers to these questions begins with a foundational understanding of laser cutting machines, the laser cutting processes, and how a metal cutting industry professional resource like Steelway Laser Cutting can streamline the process from start to finish.

How Does a Laser Cutting Machine Work?

Variations and Different Types of Laser Cutters

What is the Process of Laser Cutting?

Computer Numerical Control (CNC) Laser Cutting

The Benefits of Laser Cutting

How Does the Process of Laser Cutting Work?

Stemming from the phrase Light Amplification by Stimulated Emission of Radiation, lasers were introduced in the 1960s as a new method for fabricating and cutting materials more efficiently. Laser cutting is a heat-based precision and has the ability to repeat the cutting process as many times as necessary.

Laser cutting machines are superior to other cutting processes, such as flame cutting or metal-on-metal cutting, due to their increased accuracy and power. These machines use high-intensity and localized heating on a specific focal point on the surface of the material to produce high-power laser cuts or engraving. Additionally, they can be used virtually any time of metal, regardless of its thickness. From highly reflective materials like aluminum to thick sheets of stainless steel or mild steel, the laser light works through the material efficiently. Furthermore, it also works by vaporizing the molten material and leaving behind no waste, rough edges, or other imperfections in the material.

How Does a Laser Cutting Machine Work?

The exact laser cutting process is determined by the type of laser cutter used, and there are a few primary or more types of lasers that are used in laser cutting operations.

CO2 Lasers

Carbon dioxide lasers (or CO2 lasers) are some of the first lasers used on a large scale in manufacturing industries. Therefore, CO2 lasers are still popular for cutting metals of varying material thickness, particularly with recent advancements in laser cutting technology.

C02 lasers function by passing a current through a gas mix or by using radio frequency energy, which is a more modern and popular option in this type of laser cutting. CO2 lasers are utilized in the industrial cutting of many materials, including stainless steel, mild steel, aluminum, plastic, wood, and even paper. However, additional factors determine how well a C02 laser can tackle the laser cutting process.

The power source plays a role in the effectiveness of C02 lasers, as does the type of gas flow. Common variations in CO2 lasers include fast axial flow, slow axial flow, transverse flow, and slab. A blower or turbine circulates a mixture of carbon dioxide, helium, and nitrogen at a high velocity in a fast axial flow resonator.

A transverse flow laser circulates the gas mixture at a lower velocity and, as such, requires a more straightforward blower. Meanwhile, slab or diffusion-cooled laser resonators have a static gas field that does not require glassware or pressurization, making it a more cost-effective option when it comes to maintenance or replacement of glassware and turbines.

Regardless of the exact type of laser system, the laser generator, and the external optics (including the focus lens) will require cooling in the laser cutting process. Depending on the laser system size and the configuration, the waste heat may be transferred by a separate coolant or directly into the air. Water is one of the more common coolants, and it tends to be circulated by a heat transfer system or a chiller.

Crystal (Ruby, Nd, and Nd-YAG) Lasers

Similar to a CO2 laser, this solid-state laser uses a synthetic crystal as a laser medium, and Nd:YAG lasers are optically pumped using a flashtube or laser diodes. Although it can tackle metals with varying thicknesses, crystal lasers can be costly and complex to maintain, requiring careful design and precise alignment for optimal performance.

Fiber lasers

Fiber lasers are a modern type of solid-state laser (as their power source is silica glass mixed with rare earth elements) rapidly becoming the preferred laser cutting machine in multiple industries due to their precision and inherent laser power.

Unlike CO2 laser cutters, fiber laser cutters use a solid gain medium instead of a liquid or gas. The “seed laser” then produces the laser beam, which is, in turn, amplified within a glass fiber. With a minute wavelength of 1064 nanometers, fiber lasers can produce a very small spot size (as much as 100 times smaller than the C02 laser cutting process), which makes fiber lasers a good option for delicate or highly reflective materials.

There are additional benefits to fiber lasers as well, as opposed to their laser cutting counterparts. Fiber laser cutters have faster processing times, reduced energy consumption (which means lower utility bills) and more excellent reliability and performance, as there are no optics to adjust, and minimal maintenance.

It should be noted, however, that fiber laser cutters can be costly to operate in-house. Instead, a resource like Steelway Laser Cutting is often a business’s best option for exceptional laser cutting results while staying within a tight budget.

Variations and Different Types of Laser Cutters

Remember, there are multiple variations in every type of laser cutter that will determine the power, price, and efficiency of the laser cutting process.

For example, a laser microjet, which combines a low-pressure water jet with a pulsed laser beam, could be used. This laser system uses the water jet to guide the laser beam, like an optical fiber, through internal reflection. The cutting process removes debris while cooling the material, resulting in high dicing speeds, parallel kerf, and omnidirectional cutting.

The laser optics, how the laser moves, the laser medium, the laser head, and many other factors combine to select the effectiveness and efficiency of the laser cutting machine. In essence, the best way to determine the specific type of laser cutter for your operations is to consult with a professional resource like Steelway Laser Cutting.

What is the Process of Laser Cutting?

Regardless of the type of laser cutter used, the process of laser cutting entails directing a laser beam onto a specific workpiece of metal or other material. The laser beam is focused using a high-quality lens in the work zone. Therefore, the quality of the laser beam is directly related to the spot size, with the narrowest part of the focused laser beam clocking in at a diameter of less than 0.0125.

The laser beam is intensified and focused by correlating methods or additional tools, like adaptive mirror control, which effectively vaporizes molten material, leaving no waste or debris behind. While laser cutting machines can certainly cut materials with precise results, they can also be utilized for laser marking processes, such as engraving, depending on the exact specifications of the project at hand.

Computer Numerical Control (CNC) Laser Cutting

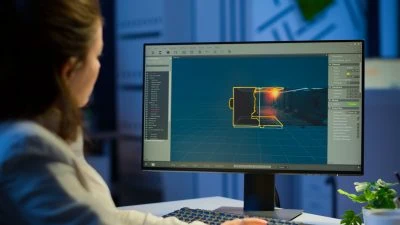

Modern commercial laser cutters use a motion control system to follow a computer numerical control (CNC) of the pattern that will be cut into the material. Therefore, CO2 laser cutting machines, fiber cutting machines, plasma cutting machines, and other types of laser cutters can all effectively be CNC laser cutting machines.

CNC laser cutting uses a high-powered laser beam to mark, cut, engrave, and form the material. Additionally, a CNC laser cutter is highly accurate and capable of creating the most minor small holes and most intricate designs.

Furthermore, CNC laser cutting is also renowned as a hands-off process, as once the instructions are fed to the laser cutter, the focused laser beam follows all specifications without human intervention. The cutting head is automatically directed as needed. This also means that all cutting processes can be repeated again and again for mass-produced production runs of a thousand units or more.

The Benefits of the Laser Cutting Process

There are a range of advantages to laser cutting over other processes that can lead to excess molten material or debris, extra waste, high power consumption, and inaccurate results.

A sample of just some of the benefits of laser cutters in manufacturing processes is as follows.

Versatility

The best laser cutters available can handle varying materials of all kinds. Anything from standard steel plates to highly reflective materials to thick sheets of metal that can be hard to fabricate with other types of cutting machines. As such, manufacturers aren’t hindered in determining what materials to use for specified parts and products, as all metals and other materials can be cut or engraved with a top-quality laser cutting machine.

A Non-contact Process

When it comes to varying cutting processes, laser cutting processes require the least amount of human involvement from start to finish. Once the computer-aided design (CAD) software instructions are fed to the laser cutting machine, the laser cutting head follows these instructions precisely, as often as required, with no alterations or pauses in operations until the project is finished. In addition, all parts of the laser cutting machine – from the cutting head to the laser beam – require no upkeep or maintenance during the operation. Therefore, all cutting processes run smoothly, without setbacks or additional challenges along the way.

Unmatched Precision

The focused laser beam of a laser cutter can create the smallest marks, cuts, holes, and engravings possible, which means that even the most intricate designs can be easily created and repeated during the laser cutting process. Because of this, manufacturers can create parts as small and intricate as required, which is why laser cutting is becoming the preferred fabrication method for industries that rely on minuscule parts, like the medical device and electronics industries.

Reduction in Waste and Expenses

Because the focused laser beam vaporizes the unwanted material and can follow the most precise specifications, there is little excess waste in the laser cutting process, as every workpiece can be maximized to create the most parts possible out of a single piece of sheet metal or other material. The reliability of the laser cutting process also ensures that mistakes or incorrect cuts are nonexistent, regardless of the instructions or how many parts need to be produced in a run, which further cuts costs for manufacturers across the board.

Faster Results

Because the focused laser beam vaporizes the unwanted material and can follow the most precise specifications, there is little excess waste in the laser cutting process, as every workpiece can be maximized to create the most parts possible out of a single piece of sheet metal or other material. The reliability of the laser cutting process also ensures that mistakes or incorrect cuts are nonexistent, regardless of the instructions or how many parts need to be produced in a run, which further cuts costs for manufacturers across the board.

The Best Way to Ensure the Best Laser Cutting Processes is to Partner with an Expert

Most businesses do not have the time, budget, and expertise to take advantage of the most modern laser cutters available. Therefore, when it comes to exceptional laser cutting processes from start to finish, a partner or laser cutting resource is enlisted to complete the job.

At Steelway Laser Cutting, we utilize the best laser cutting machines available, combined with expert operators and technicians, as well as a state-of-the-art facility, to ensure that every project is completed to perfection in the shortest time possible.

Outsourcing your laser cutting needs is an exceptional way to enjoy the benefits of modern laser cutting processes without incurring excess costs of purchasing a laser cutting machine and maintaining the delicate and expensive laser cutter equipment in-house. When you have an expert laser cutting partner guiding the way, you can revolutionize your operations from the ground up while saving time and money every step of the way.

Reach out to the expert team at Steelway Laser Cutting to start the conversation. The laser cutting process begins with an expert guide, and our professional team at Steelway is standing by to start the discussion. Discover how we can take your manufacturing operations to new heights of efficiency and success.