With laser cutting technologies continuing to advance their capabilities, the market for laser cutting machines has grown considerably and shows real promise for continued demand. Additionally, cost optimization and refinement of laser technologies have made laser cutting machines more accessible than ever before. Laser cutting is now the optimal alternative to traditional production systems such as punching and mechanical presses.

By merging the efficiency and flexibility of laser cutting with the demands of manufacturing productivity, industries across the globe now depend on laser cutting machines for efficient fabrication. At Steelway Laser Cutting, we know the benefits of laser cutting technology. In our experience, we have used laser machines to provide custom metal bending, cutting, steel welding services, and beyond to help our customers with all their fabrication and manufacturing needs.

What is CNC Laser Cutting?

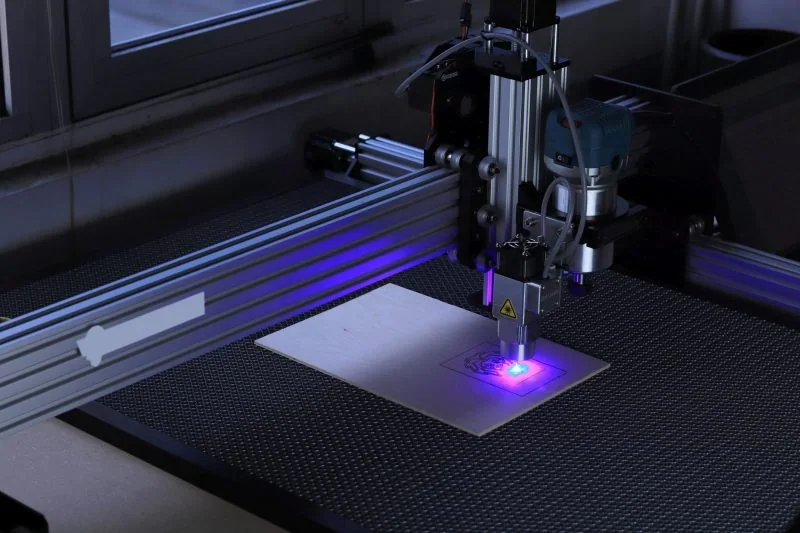

Laser cutting is a process by which intense heat is created and applied to a workpiece to vaporize, melt, or gradually remove the material in its path to achieve a bend, cut, or welded finish. Most commonly, metal cutting processes are used the most to produce accurate and precise shapes.

Computer numerical controlled (CNC) equipment uses a software program that communicates with the laser machine. The computer controls the exact velocity and positioning- back and forth or side-to-side on axes to specification. Therefore, in order to do this, an operator or programmer enters the design into a computer from a remote location and then sends the signal to start the laser machine. Here, a focused, high-powered laser beam begins to work to mark, cut, or engrave a material to form custom shapes.

How Can Laser Cutting Increase Productivity and Efficiency?

When it comes to manufacturing production, time is money. The faster you can produce a product, the more product you can process, and processing more products translates into a steady flow of revenue.

Laser cutting machines maximize efficiency and increase productivity for the entire production cycle of the fabrication process.

Speed

Laser cutting machines increase production speed without compromising the integrity or quality of components. However, they can produce parts in a fraction of the time it would take in traditional fabrication processes. A quality laser system can cut sophisticated shapes and patterns with unique accuracy in a few minutes. This type of speed makes laser-cutting a great way to increase productivity and efficiency.

Accuracy

Machine programming with the use of CNC software is a significant advantage of a laser cutting machine. The operator or programmer can create and set up a design according to product type and the kind of material to be processed. Moreover, this form of non-contact manufacturing allows for quick and easy changes, reconfigurations, and adjustments made within the computer software program. However, once the laser cutter starts, it uses a process that cuts parts without having to touch or move the material. It provides unparalleled accuracy that directly impacts productivity and efficiency.

Produce Large Quantities

Industrial manufacturing depends on automation to produce high-quality, precise parts in a very short time. Laser cutting technology can do this repeatedly. Therefore, laser cutting is widely used to produce high volumes of products. Productivity and efficiency are positively impacted by the capability of laser cutting machines to manufacture large volumes quickly.

Optimize Your Design

The right design can impact the productivity and efficiency of your project. A good design utilizes cost-saving measures without sacrificing quality. This maximizes the value of your parts and maintains the level of quality you need without wasting time and money. Therefore, consider employing an experienced sheet metal designer to help you create models and prototypes so that you can work through issues before production. Complex engraving, cutting, and marking processing that was once unworkable by traditional systems make laser cutting an efficient option.

Versatility of Materials

Depending on the final product, a variety of cutting methods can be used across a wide range of materials. No matter the type you need, the versatility of laser cutting machines helps get the job done. Researching what material is best for your design can directly impact productivity and efficiency by reducing scrap and polluting materials during manufacturing.

Laser Cutting Project Management

The supplier you use can impact the success of your project by maximizing productivity. Using a supplier to manage your project from design through delivery can ensure a high-quality product is manufactured on time and within the right budget.

Furthermore, most laser cutting services provide varying degrees of support throughout the production cycle. Some simply design, others only cut, and others might only package and/or deliver. However, laser cutting services that offer additional fabrication services and processes such as designing, prototyping, forming, welding, complex assembly, and manufacturing save you time and money.

By using one supplier for all of your complete metal cutting services, you can streamline your project by relying on a single point of contact. However, there is no need to coordinate where, when, and how to move your part to the next phase of production. This saves time and money on shipping parts between vendors and makes for a more efficient and less costly process.

Increase Production Efficiently with Steelway Laser Cutting

Laser cutting is used to provide cutting-edge solutions for large and small manufacturing jobs. Additionally, it is not used only in the industrial world, but at home, in schools, and in hospitals, too. With the use of laser cutting machines continuing to expand across different sectors of production, they are designed in different sizes and types for various purposes. This means that whatever your cutting needs are, laser cutting machines are the way to go.

If you’re looking for a manufacturing partner who will help you maximize efficiency and profitability in your own business, Steelway Laser Cutting is your team. Our experienced professionals are ready to assist you in any way we can. Find out how we can support your business and your laser cutting needs from start to finish.