Metal cutting laser machines have been around for decades, and metal laser cutting technology has grown by leaps and bounds in recent years. This approach allows more precision and more freedom in designs than ever before.

From the minor metal parts used in cell phones, medical devices, and other electronics to innovations in new construction, laser cut metal is the backbone of revolutionary new designs that are visible and used every day.

The best way for manufacturers and businesses to evolve their designs with modern laser metal cutting techniques is to partner with an expert in laser cut metal services.

Using computer aided design (CAD) software, Steelway Laser Cutting can help your company create better parts and products in a more streamlined process. Additionally, this saves time and money while allowing your company to expand and enhance your designs.

In the meantime, read on to uncover the fundamentals of how to laser cut sheet metal and other materials and how laser cutting is changing a world of industries, one well-designed product at a time.

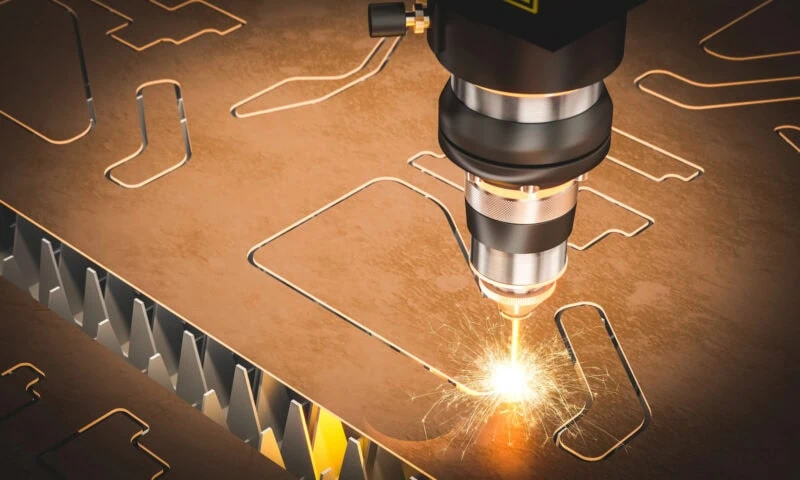

The Basics of Laser Cutting Metal

Laser cuttingis a preferred manufacturing process for many reasons, including precision.

A computer numerical controlled laser cutting machine works because the laser beam does the rest once instructions are fed to the machine. Therefore, they must follow exact specifications and make precise cuts, holes, indentations, or engravings that can be less than a millimeter in diameter. The heat produced by the laser beam is so intense that the material melts away, often instantly transforming from a solid to a gas – a process known as sublimation.

Because of this process, there is no excess waste, no jagged edges or alterations in laser cut sheet metal, and no mistakes. This means that thousands of parts or products can be mass produced with ease, even when the most intricate designs are required.

Types of Metal Suitable for Laser Cutting

Most metals can be effectively cut with a highly advanced laser cutting machine, and a sample of just some of the materials that can undergo the laser cutting process with relative ease is listed below.

- Stainless steel – Stainless steel is one of the most used sheet metals when it comes to the laser cutting process simply because it is highly corrosion-resistant, durable, solid, weather resistant, and traditionally suitable for outside use.

- Mild steel – Mild steel or low carbon steel is another common steel used in manufacturing industries and laser cutting projects because it is a cost-effective material with solid flexibility and relatively low tensile strength.

- Aluminum – Lightweight aluminum can be effectively cut and fabricated with laser cutting despite its thin and reflective nature. The key is to use a first-class and technologically advanced laser cutting machine to achieve the best results.

- Titanium – Although traditionally challenging to cut, titanium can be cut and otherwise fabricated with an advanced laser cutting machine, and its strength and lightweight properties make it a highly popular and effective material in the production of aerospace, medical, marine, and automotive related products.

- Copper – Copper is well known for its excellent electrical conductivity for plumbing and electrical applications. However, copper’s thermal conductivity requires a high-powered laser cutter for the best results.

- Brass – Known for its strength and flexibility, and despite its toughness, brass can be efficiently cut and fabricated with a laser cutting machine. Brass can be found in both functional and decorative products around the globe, including jewelry, locks, hinges, gears, bearings, automotive radiators, musical instruments, electronics, and coins.

- Other materials – Remember that laser cutting machines aren’t just used for metals. They can also effectively cut and alter other materials such as wood, glass, acrylic, and even fiber.

Everyday Applications of Laser Cut Metal in Designs

As noted, laser-cut metals and materials are visible in nearly every corner of day-to-day life, and there are a few distinctive ways that innovative designs can come to life via the laser cutting process.

Architectural wonders – Laser cutting can be used for exterior home décor like intricate gates, fences, fixtures, and other common landscaping additions, and it can also be used for the detailed touches found on iconic buildings and homes around the world.

Automotive and aerospace applications – Laser cutting has revolutionized the automotive and aerospace industries as it allows for the mass production of the most intricate parts in a streamlined and highly efficient manner. Because of this, automobiles are better designed and last longer because the parts are created with the highest level of precision and detail.

Construction industry – Laser cutting has also changed the materials that can be utilized in construction projects across the board, as both lightweight and tough metals can be cut quickly and with ease. As such, homes and structures are stronger and better able to withstand the outdoor elements,

Manufacturing – From tumblers to electronics, laser cutting can be found in every aspect of manufacturing. Popular uses of laser cutting when it comes to manufacturing parts or products include appliances, home décor, electronics, medical devices and equipment, and even commercial produced artworks or other creative projects.

The best way to expand your designs is to have access to the best laser cutting technology on the market.

Laser cutting allows companies to evolve the designs for their parts and products without sacrificing quality, cost, efficiency, and production speed. However, the key is to utilize the best laser cutting technology available optimally within state-of-the-art facilities and with expert laser cutting machine operators overseeing the varying projects.

Steelway Laser Cutting Provides the Best Laser Cutting Metal

At Steelway, we have continual access to the best laser cutting machines available, and we can handle virtually any manufacturing or laser cutting project required. With decades of experience and a fast turnaround time (even if shipping is involved), companies can save time and money while revolutionizing their design for their various parts and products.

Reach out to us today for a free consultation and to discover how an expert laser cutting resource can change the game. With Steelway as your partner, you can take your company’s manufacturing projects to a new level of design and efficiency.