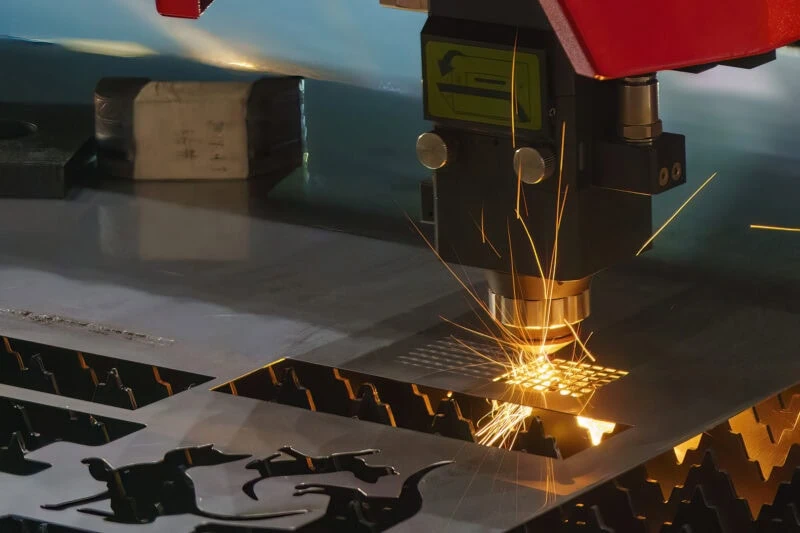

Lightweight and durable, aluminum is a preferred material in many manufacturing sectors, including the construction, electronics, and automobile industries. While a custom cut aluminum sheet can be easy to achieve through laser cutting machines, there are some caveats and considerations to remember when fabricating this distinctive metal.

When it comes to aluminum laser cutting, having an expert resource with the best facilities, technicians, and laser cutting machines is a seamless way to get perfect results on every project, regardless of scope or size. Steelway Laser Cutting can fabricate all varieties of metal – including aluminum – and can help you outsource all your laser cut aluminum requirements in the most cost-effective and time-saving manner possible.

In the meantime, keep the following information in mind when it comes to laser cutting aluminum to ensure that the process results in perfectly manufactured aluminum parts and products, time after time.

The Advantages of Laser Cutting Aluminum

There are many advantages to using advanced laser cutting machines to fabricate aluminum sheets, which include the following.

Flexibility

Aluminum laser cutting is an effective fabrication process for all varieties of aluminum sheets, regardless of different alloys or thicknesses. This is especially true when a top laser cutting machine that can handle thicker metal sheets without losing power or speed is utilized.

Efficiency

Since laser cutting is a hands-off process that is automatically repeated as many times as necessary. As a result, each cut is precise and easily duplicated, ensuring a speedy and efficient process from start to finish.

Speed

Laser cutting is a no-contact process that can run interrupted without adjustments to the cutting machine or maintenance during the project. In addition to the lack of interruptions, laser cutting is inherently faster than older cutting methods, even when it comes to thicker or more reflective aluminum sheets. As such, projects can be completed in a quick turnaround time, even if the fabrication process is outsourced and shipping to and from the cutting facility is required.

The Disadvantages or Challenges of Laser Cutting Aluminum

Like any type of metal, laser cutting aluminum sheets has its suite of challenges that can be mitigated with an expert in metal laser cutting like Steelway. A few potential hurdles to be on the lookout for include the following.

Reflectivity

Aluminum is a highly reflective or shiny material. Therefore, this inherent property can provide potential challenges when it comes to laser cutting. Essentially, aluminum can reflect the laser beam, which can damage the machine itself. The best solution is to use the best laser cutting machines that have a high frequency and can avoid this issue altogether. In addition, manufacturers conducting metal fabrication in house can opt for a less reflective aluminum alloy. This alloy contains elements such as magnesium, zinc, and silicon, although this may increase the overall cost of the raw material.

Thermal Conductivity

Aluminum has very good heat dissipation. This can be a problem during the laser cutting process as it can make reaching the high temperatures required for the cutting or fabrication process difficult. Again, an advanced laser cutting machine that operates at the highest levels of speed can resolve this issue. Therefore, it is important to melt the surface and produce the desired cuts before heat dissipation can occur.

Potential for Errors

Lower-quality laser cutting machines may leave behind mistakes or distortions on aluminum sheets, such as the formation of sharp edges and/or burrs along the cut line. A second machine process may be required to resolve these issues and create a smooth edge. Additionally, manufacturers can use a high quality and high-powered laser cutting machine to create a smoother and more accurate end product.

Factors that May Affect the Quality of Laser Cutting Aluminum

There are several factors that may impact your aluminum manufacturing projects, such as the following.

Thickness

The types of aluminum, as well as its inherent thickness, play a big role in how well any cutting machine, including laser cutting machines, can fabricate it. Thicker aluminum sheets greater than 8 mm are best fabricated with a laser cutting machine with a high-power output. The cutting process should optimally be at a slower speed to achieve the highest quality end results.

A laser cutting machine can cut thinner aluminum sheets of 1-8 mm with a lower power output and be processed at a higher speed.

Composition

Aluminum alloys have inherently different melting points, thermal conductivity, and reflectivity, all based on the inherent materials. As such, the composition has much to do with the best procedure for laser cutting, including the speed and the best machine to handle the job.

Gas Selection

Assist gases play a significant role when it comes to laser cutting aluminum, and there are several gases that are suitable for the process. Nitrogen and argon are the most commonly used assist gases, as they can help prevent the buildup of debris in the cutting area and can help create a protective atmosphere that prevents oxidation of the aluminum part while ensuring a smooth cut.

Power of the Laser

When it comes to potential issues due to reflectivity and thermal conductivity, the power of the laser beam can help mitigate any potential problems. In essence, the laser power directly influences the cutting speed, which affects factors such as the smoothness of the edges, heat generation, and possible material distortion.

A high-powered laser beam is also important when handling aluminum sheets of different alloys and different levels of thickness for manufacturers who use more than one type of metal for their end products.

For the Best Laser Cut Aluminum Services, Steelway Laser Cutting is Your Partner

At Steelway, we have the technology and expertise required to handle every metal fabrication project, which includes aluminum laser cutting needs of all varieties. Outsourcing your laser cutting is a great way to ensure perfect results for every part without sacrificing speed, efficiency, or budget.

Reach out to us today for a free consultation. Discover how we can help with your aluminum laser cutting projects. With Steelway as your partner and resource, you can enjoy the highest level of efficiency for every manufacturing project. We offer laser cutting services near Philadelphia. Steelway Laser Cutting provides precise and efficient solutions for intricate designs, particularly in the specialized task of laser cutting aluminum across Pennsylvania.