Sheet metal is one of the most widely used metals in everyday applications, from the framework of buildings and vehicles to the appliances found in every home. Understanding how to cut sheet metal is key to all these end-uses.

Steel is one of the easiest materials to fabricate when it comes to sheet metal. This is especially true when compared to thick metals like brass or copper, or thin sheets of reflective aluminum. On the other hand, some cutting methods are much more effective than others when it comes to ensuring intricate cuts.

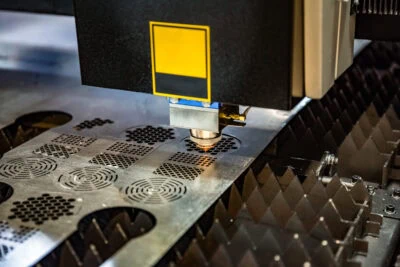

Advanced laser cutting machines can easily and efficiently cut sheet metal. They are generally considered the best tools for cutting metal, particularly steel. However, the process requires an expert in CNC laser cutting capabilities.

Steelway Laser Cutting has been helping businesses across all industries transform sheet metal into the parts and products we use every day. Our team of experts are the best resource for finding a reliable and cost-effective solution for cutting and fabricating steel and other varieties of metal sheets.

However, having a basic understanding of how advanced laser cutting can transform the metal cutting process will help businesses of all sizes launch a better and more effective method to cut sheet metal.

Table of Contents

The Properties and Characteristics of Steel Sheet Metal

Variations in Thickness and Grade

Laser Cutting for Thin Sheet Metal

Types of Steel Sheet Metal

Traditional Methods of Cutting Sheet Metal

Laser Cutting Steel Sheet Metal

The Benefits of Laser Cutting for Sheet Metal

Research the Best Laser Cutting Technology

Learn More About the Best Ways to Cut Steel at Steelway Laser Cutting

All About Steel Sheet Metal

Steel sheet metal is a highly versatile and common metal with limitless applications. Generally varying in thickness from roughly .5 mm to 6 mm, steel sheet metal can be fabricated in several ways. In addition, steel metal sheet generally comes in a wide range of grades and finishes.

The properties and characteristics of steel sheet metal

There is a long list of reasons steel is a popular sheet metal in industrial applications. A handful of these reasons include the following.

- Strength – Steel sheet metal is both durable and strong. It can handle heavy loads and resist deformities due to heavy use. It’s also resistant to corrosion, making it ideal for outdoor applications in various weather conditions.

- Versatility – Steel sheet metal can be fabricated in any number of ways, as it can be welded, modeled, cut, and shaped with relative ease. As such, steel sheet metal can be transformed into several potential uses.

- Stability – Steel is rigid and can resist deformation well in the cutting or fabrication process and in its end-product uses.

- Low weight – Steel sheet metal is inherently lightweight, making it easy to transport. It also has a better strength-to-weight ratio than many other metals and building materials.

- Toughness – Steel’s inherent toughness makes it easier to fabricate when it comes to cutting sheet metal. It also means that it is less vulnerable to scratches and deformities, resulting in cleaner cuts.

- Safety – Steel is not combustible and does not release harmful gases or components when heated, making it safe to use in all manufacturing applications.

- Recyclability – Steel is also a recyclable metal, and scrap metal can be easily melted down and reformed into steel sheet metal or other possible uses.

Variations in Thickness and Grade

Thickness

Steel sheet metal can come in all forms, from thin sheet metal to thicker sheets. However, the most common thickness is around 9/64 to 1/16 inches. The thickness of steel sheet metal is measured in gauges, with the high numbers typically indicating a thinner sheet metal, but this can vary based on the exact type of metal.

Grade

Steel sheet metal also comes in varying grades, which indicates any additional properties inherent in the metal. For example, an “L” grade indicates a lower carbon level, which generally translates into reduced strength but an improved ability to undergo other fabrication processes, like welding. An “N” grade refers to nitrogen, which can lead to an increase in tensile strength.

Laser Cutting for Thin Sheet Metal

Laser cutting is a precise and efficient method for cutting thin sheet metal, offering several advantages over traditional metal cutting methods. With the ability to make intricate cuts and designs, laser cutting is ideal for various applications, including metal fabrication, automotive, aerospace, and construction.

Whether you’re working with thin sheet metal for detailed components or larger projects, laser cutting ensures accuracy and efficiency, making it a preferred choice for professionals across industries.

Types of Steel Sheet Metal

There are also different terms thrown around for the different types of steel, like mild steel, carbon steel, and stainless steel. An overview of these common types of steel sheet metal is as follows.

Stainless steel

Stainless steel is available in many different grades, and each of these grades has its own set of properties and uses. In addition, stainless steel is primarily made of iron and carbon, but it also contains chromium and other elements. These elements include nickel, molybdenum, nitrogen, and magnesium, and they are used in countless industrial and manufacturing applications.

Stainless steel is known for being exceptionally resistant to corrosion. It’s also heat resistant, strong, and 100% recyclable. There are more than 60 grades of stainless steel, which makes it versatile and able to fulfill all kinds of different manufacturing needs.

Carbon steel

Carbon steel is an alloy of iron and carbon, of which carbon serves as the primary alloying element. You’ll find carbon steel in machinery, cookware, and oil and gas industry applications because it’s inexpensive, easy to fabricate, and is readily available.

Carbon steel is also strong, hard, and flexible. However, it may be more difficult to weld than stainless steel or other metals and can be a little more vulnerable to breaking. Based on the carbon content and other mechanical properties, carbon steel comes in many different grades.

Mild steel

Mild steel is a type of carbon steel known for its low carbon content, as well as its versatility. You’ll find carbon steel in a wide range of products and structures, including vehicles, buildings, fences, and signs.

Mild steel is more flexible than other kinds of steel, which makes it easy to shape, form, weld, and fabricate in any number of ways, provided you have the right tools (namely, advanced laser cutting machines). It has a relatively high tensile strength, so it can handle a range of applications. However, it is more susceptible to rust than other kinds of steel sheet metal.

Galvanized steel

Galvanized steel is a type of steel coated in zinc to add an extra layer of corrosion resistance, especially in extreme outdoor environments with excessive moisture or high humidity. As a result, galvanized steel is ideal for outdoor purposes, but it can be more difficult to fabricate without advanced laser cutting technology guiding the way.

Traditional Methods of Cutting Sheet Metal

Prior to the advent of modern laser cutting tools, steel was generally fabricated using shearing, saw cutting, punching, stamping, and other production methods that were effective, but could have flaws in accuracy.

For example, typical saw cutting or fabricating steel with power tools could easily result in jagged or rough edges or a pattern that deviated from the original specifications, resulting in excess waste and inefficiency.

Laser cutting has changed sheet metal fabrication. However, these older tools are being replaced by the top manufacturers in the world in favor of more cost- effective and accurate laser cutting-based tools for cutting sheet metal.

Laser Cutting Steel Sheet Metal

When it comes to varying ways to cut metal, laser cutting reigns supreme.

From straight cuts to curved cuts, to engravings even the most intricate designs can be accomplished when you cut sheet metal with advanced laser technology.

The Benefits of Laser Cutting for Sheet Metal

Preparation for laser cutting sheet metal

Cutting sheet metal with a laser cutting machine starts with the specifications. Typically created with computer- aided design (CAD) software, the instructions are fed to the laser cutting machine (like a plasma cutter, CO2 cutter, or fiber laser cutter) that will be cutting the metal sheet.

Executing the laser cut

From there, the laser cutting machine is guided with computer numerical controls, (which is why modern laser cutting processes are referred to as “CNC laser cutting.”)

Once the laser cutting machine is ready to cut sheet metal, the process begins. The laser beam is highly focused and concentrates on the area of the sheet metal that needs to be cut or otherwise fabricated.

The heat of the laser beam effectively vaporizes the steel or other sheet of metal, leaving behind no jagged edges or excess waste. In some instances, an assist gas may blow away any molten material that stems from the metal cutting process to add extra assurance that there are no deviations from the specifications.

Unlike older methods of cutting metal, which may use a metal cutting blade, laser cutting for sheet metal leaves no waste behind and does not stray from the exact specifications of cut sheet metal.

Once the laser cutting process begins, it can be repeated– for a thousand parts or products or more – until the production run is finished. In the end, every cut sheet metal piece is perfectly replicated, with no alterations from one part or product to the next, which is why laser cutting is the preferred method to cut sheet metal in hefty and large-scale manufacturing operations.

Tips for Achieving Precise Sheet Metal Cuts in the Laser Cutting Process

While the laser cutting process is well known for its accuracy and efficiency, there are a few tips and extra steps that can make it even easier to fabricate sheet metal of all varieties.

Pay attention to the sheet metal properties and the laser cutting machine

The settings and ensuing process for cutting sheet metal will vary based on the type of steel (or other metal) and the type of laser cutting, like plasma cutting versus fiber laser cutting. Make adjustments as needed, as cutting thin sheet metal material may require different steps and settings than cutting thicker metals.

Do a test run first

Doing an initial test run will ensure that the metal cutting process goes smoothly from start to finish, especially when it comes to large production runs of 1,000 metal parts and/or products or more. This is especially important for more intricate designs that require high levels of attention to detail, although the laser metal cutting process is renowned for its efficiency and accuracy.

Research the Best Laser Cutting Technology for the Best Results

Laser cutting is a metal cutting process that has been around since the 1960s. Furthermore, laser cutting has been used in widespread industrial applications since the 1980s. However, waves of advancements over the last few years have revolutionized a laser cutter’s ability to cut metal, provided that the best and most advanced laser cutting machines and subsequent technology are utilized.

Simply put, not all laser cutting machines are created equally, and you need the most advanced laser cutting machines and facilities for the best results when it comes to the ability to cut steel and to cut metal sheets of all varieties. The best laser cutting machines and facilities are often too expensive to purchase in-house. That is why experienced outsourcing metal cutting providers like Steelway Laser Cutting are an exceptional resource.

Reach Out to a Laser Cutting Expert

The best way to ensure perfect results when it comes to cutting steel and other sheet metal materials is to partner with a third-party resource that can produce exceptional results, time after time.

Most businesses simply don’t have the budget to laser cut metal sheets in-house to absolute precision and perfection, especially if many metal parts or products are required. Therefore, they outsource this step in the production process to an expert.

Enlisting a laser cutting services provider can save valuable time and money, even if shipping of the raw sheet metal material and end-result products is involved.

In addition, laser cutting services providers have access to the best laser cutting machines in the industry, the best facilities to ensure the operation runs smoothly, and in-house technicians with much experience in the modern laser cutting process.

Learn More About the Best Ways to Cut Steel at Steelway Laser Cutting

When it comes to sheet metal fabrication in all its forms, Steelway laser Cutting is the expert in ensuring every manufacturing project is completed to perfection.

We have decades of experience in laser cutting but rely on the latest and most advanced laser cutting technology to ensure client satisfaction with every job.

Reach out to us today to start the conversation. Our team will have your questions answered about the best ways to cut steel with advanced laser cutting services. With Steelway Laser Cutting guiding the way, you can propel your operations to new heights of success and efficiency with every metal cutting project you launch.