Businesses of all sizes can benefit from the precision, accuracy, and power of fiber laser cutting machines to expertly transform a variety of metals and other materials. A fiber laser machine is an advanced tool that is utilized by many different industries and initiatives, including construction, automobile manufacturing, electronics, and artistic endeavors.

However, what is a fiber laser machine, and how does a fiber laser cut machine work? More importantly, how can you find the best custom carbon fiber laser cutting service and fiber laser engraving service outside of conducting a simplified “fiber laser cutting service near me” online search?

In addition, fiber laser technology is far more advanced than traditional and older cutting, engraving, or other fabrication methods. However, the process can basically be broken down by the following steps, and crucial elements.

Fiber Laser Technology – How it Works

Fiber laser technology results in a focused, high-powered laser beam that can cut through virtually all types of metal or other materials. These materials include wood, leather, or even more delicate non-metal materials such as glass and plastic.

The basic and foundational principles of laser cutting machines are generally the same. They are characterized by a high level of automation that consistently produces accurate and precise results. The primary distinction between a fiber laser machine and its counterparts lies in its energy source.

The Basic Steps of a Fiber Laser Cutting Machine

Step 1 – Generating the laser light

In a fiber laser cutting machine, the source of the laser light is an optical fiber that is doped with a rare-earth element, such as ytterbium, thulium, dysprosium, or holmium. This enhances the ability to produce the laser light and determines the wavelength.

Step 2 – “Pumping” the laser light

This doped fiber is then excided using diode lasers, a process known as pumping. The energy from the diode lasers is absorbed by the electrons in the fiber to create a higher state of energy.

Step 3 – Creating the laser light

As the electrons return from an excited state to their normal state, they release photons. These photos then stimulate other excited electrons to release even more photons, creating a continual chain reaction that generates highly focused laser light.

Step 4 – Directing and focusing the laser light

Once the powerful laser beam has been generated, it is delivered to the cutting head of a fiber laser machine through a flexible fiber optic cable. The flexibility of the cable is important because it allows for the overall control of the laser beam.

This tends to make fiber laser cutting machines much more versatile than other types of laser machines due to a higher level of control and manipulation of the beam itself. As a result, fiber laser machines are used in a wide array of applications besides cutting, such as engraving and texturizing various materials.

The laser beam is focused and directed to the workpiece’s surface at the cutting head using a unique l lens on a curved mirror. This also contributes to the high level of precision that fiber laser machines are renowned for.

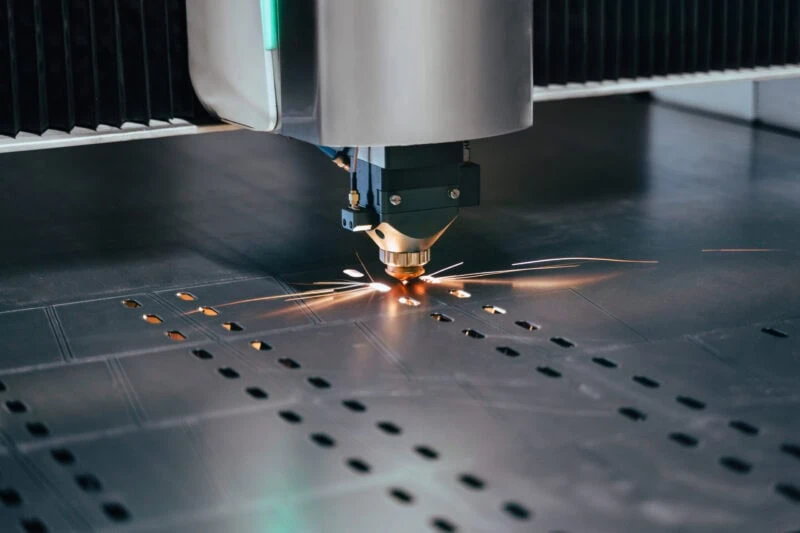

Step 5 – The fiber laser cutting process

Once the focused laser beam hits the workpiece, it rapidly heats and vaporizes the material. Sometimes, this occurs with the help of an assist gas used to blow any molten material out of the cut to ensure clean and straight edges.

In the best and most advanced fiber laser machine systems, automation is a cornerstone of achieving perfectly accurate results. The design for the cuts, engravings, or other manipulations is created with computer-aided design (CAD) software, and the laser head is guided through a computer numerical control (CNC) system and guided process. As a result, the fiber laser machine can create identical and detailed cuts, even in mass production runs of a thousand units or more.

Advantages of Fiber Laser Cutting

There are a wide range of advantages when it comes to fiber laser machines, and a handful of these advantages include the following.

Top level of precision and accuracy

Fiber lasers can produce extremely tiny, detailed, and precise cuts or engravings, with exceptional edge quality. Since fiber laser machines can tackle even the most complex designs, they are an extremely popular fabrication option for parts and products that require the most intricate details, like electronics, or artistic creations.

High speed

Fiber laser machines are powerful and fast. This increased speed results in much higher levels of productivity, especially for the mass production of many parts or products where the design must be identical every time.

Versatility

Another significant benefit of fiber laser machines is that they can tackle a huge array of metals and other materials, even tougher metals like copper, brass, and/or certain types of steel, as well as more delicate materials like aluminum or glass.

Energy efficiency and less waste

Fiber lasers produce a very narrow heat-affected zone, which minimizes any thermal distortion of manipulated materials. In addition, because of the automation involved, there is less waste due to human errors or alterations in each part or product.

Fiber laser machines are also known for their exceptional energy efficiency, especially compared to other laser cutting machines like C02 laser machines. They convert a higher percentage of power directly into the laser beam, resulting in lower operational costs and lower energy consumption from start to finish.

Access the Best Fiber Laser Cutting Technology in the Industry with Steelway Laser Cutting

Many businesses find that they simply don’t have the budget or the resources to employ the best laser cutting technology and technicians in-house, but this is where Steelway Laser Cutting shines.

At Steelway Laser Cutting, we have the expertise, advanced laser cutting machines, and facilities required to complete even the more extensive and intricate jobs while staying within your budget and timeline.

We’ll work together to ensure the most advanced laser cutting technology is available. With Steelway Laser Cutting, you have a ready partner that can make your operations more productive and more profitable from the ground up.