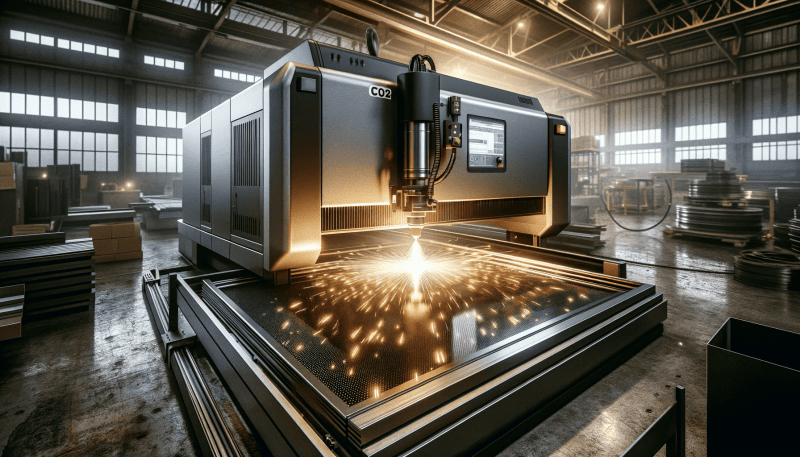

Laser cutting machines have been around for decades, and one of the first – and still most popular – types of these innovative tools is the CO2 laser cutting machine.

When it comes to cutting, bending, and shaping metals and various other materials, CO2 laser cutting is one of the most-used methods around the globe by manufacturers across all industries and sectors.

But how does a CO2 laser cutter work, and how can you use this innovative technology for your metal fabrication needs? It starts with understanding the fundamentals of CO2 laser metal cutting. Additionally, we will discuss how you can partner with an expert to increase the efficiency and productivity of your manufacturing operations.

The Basics of CO2 Laser Cutting Machines

CO2 lasers stand for carbon dioxide lasers, and these machines use carbon dioxide to create a laser beam that can cut or engrave any number of materials. However, many modern laser cutting machines are available in our modern era. The CO2 laser cutting machines are also among the most time-tested, established, and powerful. Furthermore, the most advanced CO2 laser cutting machines are known for their speed, accuracy, and ability to work with all kinds of materials.

How Long Have CO2 Laser Cutting Machines Been Around?

Believe it or not, CO2 laser cutting is not necessarily a new technology. The first CO2 laser cutting machine was invented in 1964 by laser physicist Kumar Patel in the Bell Laboratories of the United States. However, it wasn’t until the last 10-20 years that the technology has truly advanced to handle more extensive production needs of companies around the globe.

How Does a CO2 Laser Cutting Machine Work?

A C02 laser cutting machine has a number of moving parts to allow it to cut metals and other materials effectively.

These components include the following:

Creating the Laser Beam

The advanced and modern CO2 machines create a high-power and highly focused laser beam in a sealed glass tube filled with carbon dioxide and a potential mix of other gases like nitrogen and helium. During the cutting process, a high voltage flows through the glass tube, reacting with the particles within it to create energy, light, and heat so strong that it can vaporize a work surface.

Directing the Laser Beam

In order to focus the laser beam, modern CO2 laser cutting machines rely on mirrors, starting with the reflective mirrors and at either end of the glass tube. The generated light is reflected from one side of the tube to the other, increasing its inherent intensity. Eventually, this light becomes powerful enough to pass through external mirrors, which in turn directs the laser beam in the desired direction.

A final mirror inside the laser head is crucial in refining the path of the laser beam because of the detailed technology. Therefore, the laser beam can be focused from around a 7mm diameter down to approximately a 0.1mm diameter. Creating and focusing a powerful laser beam on a workpiece leads to precise and clean cuts or engravings. Therefore, the heat of the laser is sufficient to vaporize the material, eliminating any excess waste during the process.

How the CNC (Computer Numerical Control) System Plays a Role

One noticeable difference between modern CO2 laser cutting machines and their early predecessors is the use of CNC (Computer Numerical Control) systems to perform the jobs at hand. Today, there is little human involvement in the laser cutting process. Since software-generated instructions are fed to the laser cutting machine, the machine does the rest.

Essentially, these specifications are given to the CNC system, which then directs the laser beam to move in the direction outlined in the original instructions. By working together, the mirrors and lens, the focused laser beam can quickly move throughout the workpiece to create the desired cuts and/or engravings at supremely accurate levels.

What is a CO2 Laser Cutting Machine Used For?

The most powerful CO2 laser cutting machines can address virtually any project or material. A sample of materials that can be cut, engraved, or otherwise altered with a CO2 laser cutting machine includes the following:

- Metals, including stainless steel, aluminum, copper, brass, and more

- Wood

- Plastics

- Acrylic and plexiglass

- Glass

- Textiles

Remember that the type of projects that a CO2 cutting machine can handle depends on the machine type and power. Inexpensive or older machines may not be able to handle thick or tough materials with as much ease as more modern machines, and/or the process may be slower from start to finish.

What Are the Advantages of Laser Cutting Machines?

Compared to traditional metal-on-metal cutting methods, laser cutting machines – including CO2 laser cutting machines – have a world of benefits. A sample of these advantages include the following:

- Better precision and the ability to create more detailed cuts or engravings

- A faster process that can run uninterrupted

- Less downtime due to machine maintenance or variations

- Fewer errors due to a completely automated process

- More productivity due to an increase in speed and accuracy

- Less or almost zero waster material

- Better reliability for every project

Learn More About CO2 Laser Cutting with Steelway Laser Cutting

Laser cutting can revolutionize the way a manufacturer or business conducts operations. That is because it creates a faster, more accurate process for cutting every metal part.

However, the key to taking advantage of the benefits of a CO2 laser cutting machine is to partner with an expert in laser cutting technology with the best resources, facilities, and personnel available to optimize every job.

At Steelway Laser Cutting, we work with companies across all industries to complete intricate projects that require 1,000 units or more. Our laser cutting machines are state-of-the-art. Regardless of the raw materials or work required, they can handle virtually any project in a lightning-fast turnover time.

Ready to learn more? It starts with a conversation with our team of laser cutting experts.

Contact us today to explore our CO2 laser cutting services in Philadelphia and reach new heights in craftsmanship and quality!