Laser cutting is becoming the preferred method to address materials in the manufacturing process across multiple industries, and it is not difficult to see why. Dependable, accurate, and timely, computer numerical controlled CNC laser cutting can ensure exceptional results for every project, regardless of scale and complexity.

However, did you know that laser cutting also saves money due to its effectiveness in reducing waste?

More and more manufacturers are utilizing laser cutting because of this benefit. Therefore, not only does CNC laser cutting improve manufacturing processes for the environment, but a reduction in waste also results in cost reduction.

Furthermore, how can you expect to save time and minimize waste through CNC laser cutting? Let’s examine the different ways you can save time and minimize waste.

Make More Effective Use of Materials

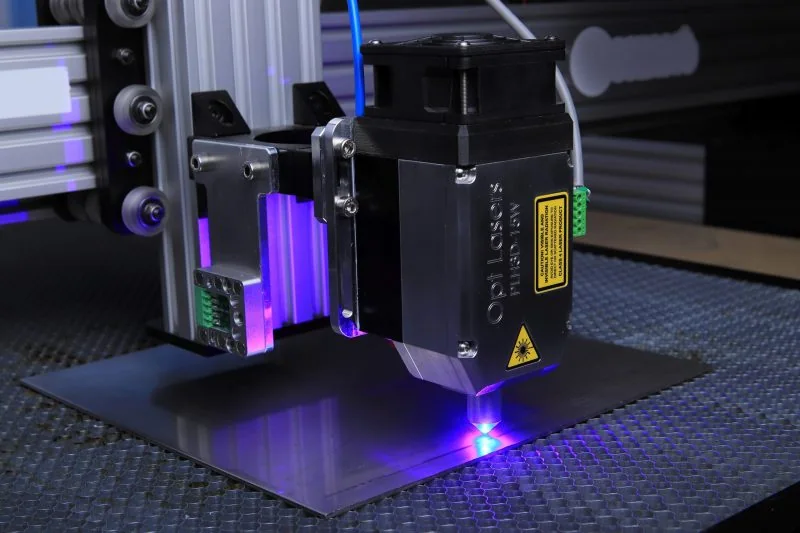

An immediate sign of waste reduction is simply in the amount of materials you will use for any project. CNC laser cutting entails delivering detailed instructions to the laser cutting machine via a software program, creating the most accurate and precise cuts possible. Especially if you use the most technology-advanced laser cutting machines in the business, as we do at Steelway Laser Cutting.

As a result, you don’t have to create extra space or regions in your sheet metal, aluminum, or other materials to account for broader cuts with extra room for error. This is because laser cutters are so precise that the maximum amount of materials can be used for every project, regardless of the individual product or task.

Increased Production & Fewer Mistakes

Another benefit of CNC laser cutting is that it is inherently a hands-off process. Since the software manages the process from beginning to end, laser cutting involves minimal work and human interaction. As such, there are virtually zero mistakes along the way, so you will not waste materials on incorrect cuts or human error.

Efficient Intricate Shapes and Designs

Some of our clients’ toughest hurdles are often transforming materials into intricate shapes and designs. Including bends, curves, exact edges, and other features that are difficult to create. However, when laser cutting is utilized, the shapes and textures you can create are as intricate as you need them.

The only limitation on the ability to focus laser beams for CNC laser cutting is the diffraction limit of the light’s wavelength. Therefore, cutting and etching very small structures is possible, and you don’t have to worry about piecing together multiple materials to create a finished product. Instead, you can craft the materials you need to your exact specifications from the beginning.

Requires Less Energy

When it comes to the environment, laser cutting machines are also inherently eco-friendly simply because they tend to use less energy than their antiquated predecessors. In addition, lasers are relatively low maintenance in terms of needing new parts and upkeep. At the same time, cutting blades require regular replacement, which can enhance energy and material costs. That is because a project must be altered or haltered across the board to account for an outdated malfunctioning cutting machine.

Also, laser cutting is not a new process for manufacturing industries. In fact, laser cutting has been around for decades. Furthermore, it has been used around the world for everything from home construction to automobiles.

CNC Laser Cutting is Your Best Option

CNC laser cutting is setting the bar for precision cutting much higher than traditional cutting machines simply because it is technologically advanced. From making the most out of every piece of material, to limiting the potential errors, CNC laser cutting is the best option for precision and accuracy every step of the way.

Reduce Waste and Achieve Results with Steelway Laser Cutting

For our clients and partners, this means cost savings at every step of the cutting process. There is minimal labor involved and little to no maintenance or adjustments once the cutting process begins. There is also a limitless number of shapes that can be created based on your detailed specifications.

Learn more about CNC laser cutting and how our decades of experience can help your company save waste and money. Let’s work together to find a better solution to your manufacturing processes from start to finish.