Businesses, manufacturers, and even hobbyists and artists have multiple options when it comes to making intricate engravings and markings in metal parts and products.

However, a fiber laser engraver or laser cutting machine is one of the best tools for allowing metal designs to come to life.

A laser machine for engraving can handle the most thorough marks and specifications using the most advanced technology available. It can also tackle the mass production of multiple units at once without deviation.

Furthermore, a specially designed laser engraving machine for metal raises the bar when it comes to efficiency, precision, and intricacy. However, the operational and equipment costs of acquiring a fiber cutting laser machine and/or laser engraver for metal projects can be prohibitive.

Finding an Exceptional Laser Engraving Service Provider for Optimal Results

Many businesses and manufacturers turn to a laser engraving service provider to have access to the best technology possible without having to face additional challenges.

When it comes to finding a laser engraving service provider, you can certainly do an online search of “metal engraving near me” or “laser engraving services near me” and be flooded with results. However, the best path forward is to start a conversation with an established and experienced expert like Steelway Laser Cutting. Our company has the tools and resources, as well as a primary focus on exceptional customer service, to ensure every project is completed for our client’s total satisfaction.

In the meantime, let’s discover the fundamentals of a fiber laser cutter and engraver and what sets this technology apart when it comes to traditional metal cutting and engraving machines.

How Fiber Laser Engravers Work

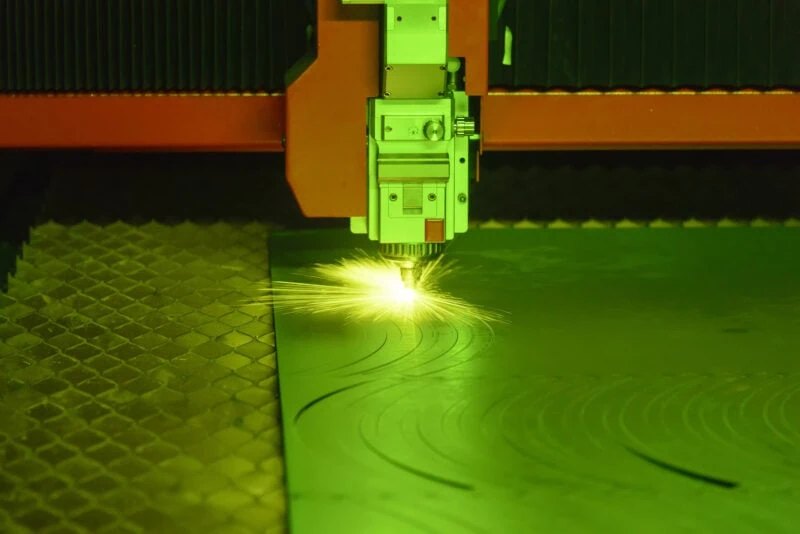

A fiber laser engraver is a relatively new advancement in engraving machines. Due to its unparalleled speed, accuracy, and versatility, it has revolutionized the engraving process. This technology works via a fiber-optic cable that transmits the energy of a laser beam to the engraving head. The laser beam is then focused onto the material’s service and is guided to create the desired etchings and marks. The laser beam is so hot that it effectively vaporizes the material’s surface, removing a thin top layer of the material without leaving behind excess debris.

Unlike older or more traditional engraving machines, the fiber laser engraving technology is unique in that the material that is undergoing the engraving process does not come into contact with the primary engraving tool. This reduces the risk of damaging both the material as well as the engraving head, and further enhances both precision and quality.

In addition, the best laser engraving service providers couple this fiber technology with automation, including computer numerical control (CNC) that guides the laser beam without human involvement or manual operation. Once the design has been finalized through computer-aided design software, the fiber laser engraver or fiber laser cutting machine does the rest, following the exact specifications time after time and replicating a design perfectly, with no distinction between one part or product and the next.

What Type of Materials can be Engraved with a Fiber Laser Engraver?

One of the significant hallmarks of a fiber laser engraving machine is its versatility. Unlike other types of engravers, the no-contact fiber laser engraver can work with a wide array of materials, which includes the following

- Stainless steel

- Aluminum

- Brass

- Copper

- Titanium

- Silver

- Gold

- Platinum

- Chrome

- Plastics

- Fiberglass

- Synthetic leathers

- Ceramics

- Many, many other materials

In short, there are very few limitations when it comes to the materials that a fiber laser engraver can work with, and a fiber laser engraver can also handle the most intricate markings or designs. For specifics on laser engraving (Philadelphia area and beyond), reach out to Steelway Laser Cutting to discuss the details of your laser engraving needs and how we can help.

The Advantages of Enlisting a Fiber Laser Engraving Service Provider

There is a long list of benefits when it comes to a partnership with an established company that can use the most advanced fiber laser engraving technology to address your projects and manufacturing needs. These benefits include the following:

Speed

Even with shipping, the speed of fiber laser engraving services is unmatched, especially for large manufacturing orders or projects of 1,000 units or more.

Precision

With the most advanced technology utilized from the initial design to the actual engraving or cutting process, the precision of fiber laser machines is simply unmatched. Relying on automation ensures consistent design and precise handling of even the smallest cuts or marks across all parts or products.

Less waste means more efficiency

Because of this precision, there is less waste across the board. With fiber laser engraving technology, you will not have to worry about discarding parts or products due to errors during the engraving process.

Eco-friendly

Fiber laser engraving is also exceptionally eco-friendly, as the technology uses very little energy and produces the bare minimum of waste. The process also does not require any consumables, such as ink or cutting tools, and is a non-toxic process free of chemicals or hazardous fumes.

Creative freedom

Fiber laser engraving technology also gives businesses and manufacturers the freedom to create and execute any design they want. From intricate artwork to tiny serial numbers or instructions, any design can come to life with a fiber laser engraver. This allows companies to improve their products and expand and grow their designs, logos, and other markings however they wish.

Experience Benefits of Fiber Laser Engraving with the Right Provider

Steelway Laser Cutting is your best resource for finding revolutionary new ways to engrave, cut, and otherwise alter sheet metal and other materials into the parts and products you need.

Our team has decades of experience in laser cutting technology, and we’re always available to answer questions, provide a quote, or discuss how we can use our expertise to your best benefit.

Reach out to us today to start the conversation. With an expert partner behind the scenes, you’ll be amazed at how you can streamline and grow every instrumental aspect of your design and manufacturing operations.