Sheet metal is utilized as the raw material for various parts and products in the manufacturing industry. As such, manufacturers need reliable and infallible production and fabrication processes for metal sheets to ensure every custom cut metal part is crafted to perfection.

Traditional and mechanical cutting tools can certainly be used to fabricate various metals and materials, like stainless steel sheet metal. However, when it comes to ensuring the error-free production of metal products, companies across all industries need a better, cutting-edge means of production.

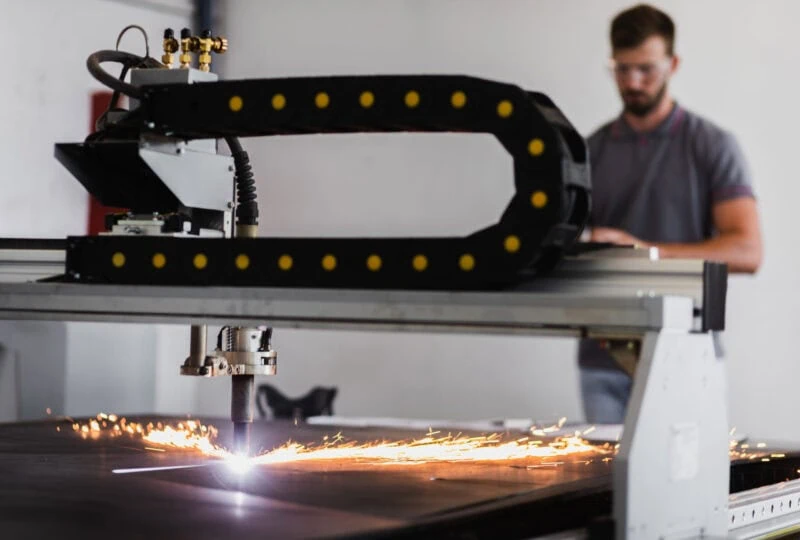

This is why laser cutting is the preferred fabrication process for metal sheets in multiple manufacturing industries, from automotive and construction companies to artisans and electronics suppliers. With the ability to cut, shape, bend, and engrave any type of sheet metal material –while maintaining the metal’s inherent properties and durability, a laser cutting machine is a game changer in the manufacturing production process.

Table of Contents

What is Steel Plate Cutting?

Can You Cut a Steel Plate?

Can You Cut Metal Sheets?

What Type of Metal Sheets Can a Laser Cutting Service Provider Cut?

What is the Best Tool to Cut Metal Sheets?

Transform Your Metal Sheets with Steelway Laser Cutting

Expert Custom Cut Steel Sheet Metal with Steelway

Utilizing laser cutting technology to custom cut metal sheets is a difficult process to conduct in-house. The best laser cutting machines for stainless steel sheet metal, aluminum sheet metal, or even steel plates are inherently expensive to purchase, maintain, and operate.

Highly specialized technicians who know the equipment inside and out are required, and manufacturing companies also need state-of-the-art facilities to ensure every fabrication project that utilizes sheet metal is completed to perfection.

An expert resource in custom cut sheet metal will make the fabrication process streamlined in every way and is a cost-effective way for manufacturers in every industry to access to best laser machine technology and expertise.

Take a closer look at how the custom cut sheet metal process works when laser cutting technology is involved and how you can harness this power of an expert supplier like Steelway Laser Cutting.

What is Steel Plate Cutting?

As manufacturers in virtually every industry know, steel plates are a material with a wide range of industrial applications, but they can be very difficult to cut, bend, punch holes in, weld, shape, and even engrave with a traditional and mechanical cutting machine.

The key elements of a steel plate and how it differs from metal sheets, are as follows:

- Thickness of a steel plate: A steel plate is noticeably thicker than steel sheet metal. Steel sheet metal can generally range from .5mm to 6mmin thickness, while a steel plate is 6mm in thickness or more.

- Uses of steel plates: Steel sheet metal is typically used in applications like car bodies in the automotive industry, metal appliance frameworks, and roofing due to both its flexibility and durability. Steel plates are often found in construction and machinery, as they typically provide heavy-duty applications where strength is required.

- Manufacturing and fabrication of steel plates: Steel sheet metal is usually cold-rolled to ensure precision, while a steel plate can be hot-rolled to accommodate a large-scale project.

Can You Cut a Steel Plate?

Steel plates can be cut with varying equipment, including laser cutting, plasma cutting, and mechanical methods. However, the cutting process for a steel plate is best completed with a more advanced laser or plasma cutting machine.

This is because more advanced equipment and machines simply have a better ability to cut and fabricate steel plates and steel metal sheets that are inherently thicker. A thicker steel metal plate or steel metal sheet is more likely to have burrs, rough edges, and other imperfections in the cutting process, simply because the thickness of the steel is more difficult to cut and fabricate without ample power and a smooth cutting method.

In laser cutting, the heat of the laser beam vaporizes the thick steel plate metal material, leaving behind no waste and creating a smooth surface on the edge of every cut.

An expert laser cutting service provider like Steelway Laser Cutting can provide more insight on how the laser cutting process works when it comes to a steel plate, and how this process can benefit your industrial applications to create the custom cut metal parts and products you require, without sacrificing quality or durability.

Stainless Steel and Other Sheet Metal Cutting

Most custom cut metal parts begin in sheet metal form, and sheet metal is the base for metal parts and products in any industry where the ability to cut, shape, bend, and weld metal to create a product is required.

Can You Cut Metal Sheets?

Metal sheets come in varying forms, like stainless steel metal sheets, aluminum metal sheets, and other kinds of steel metal sheets with varying alloys. Regardless of the exact qualities or thickness of your stainless steel metal sheets or other sheet metal materials, the best method to cut custom parts is arguably plasma or laser cutting technology.

Like a steel plate, more advanced cutting technology for metal sheets results in better precision, especially when additional technology is utilized behind the scenes, like computer numerical control and computer-aided design software.

The exact process for stainless steel sheet metal cutting (and other fabrication projects that start with metal sheets) is outlined below but rest assured that regardless of the sheet metal properties and thickness, an experienced laser cutting service provider can provide exceptional results for every project.

How to Cut Metal Sheets with a Professional Laser Cutting Service Provider

Manufacturing companies have suppliers for virtually all aspects of their production process, so enlisting a laser cutting service provider to custom cut metal parts from metal sheets is one more way to create an easier cutting, bending, or engraving process to produce top-quality results.

What Type of Metal Sheets Can a Laser Cutting Service Provider Cut?

The first step in enlisting a service provider to custom cut metal sheets is to understand the types of metal sheets and other materials that the supplier can cut and fabricate.

The best laser cutting service providers have detailed information and resources on their websites about the kinds of metal sheets they can accommodate. These online features may include the service provider’s sheet metal and other material capabilities, contact info for instant quoting (with the ability to upload PDF files of the custom cut metal part designs), instant pricing for a project, and the ability to order online.

However, the best custom metal cutting service providers can work with the following types of metal sheets or other materials.

Stainless Steel Sheet Metal

Stainless steel sheet metal is arguably one of the most common metal materials in the automotive, appliance, and construction industries. Therefore, it’s a sheet metal material that the top laser cutting service providers often work with. Stainless steel sheet metal with varying alloys and in varying degrees of thickness can also be cut and fabricated by a top-rated service provider, allowing flexibility to create parts and products out of metal sheets to your exact specifications.

Other Types of Steel Sheet Metal

Other types of steel metal sheets besides standard stainless steel sheet metal (like mild steel or even coated stainless steel sheet metal) can also be easily cut and fabricated with laser cutting technology.

Aluminum Sheet Metal

Aluminum sheet metal is another common metal found in the automotive and construction industries. Despite aluminum’s delicate and reflective properties, aluminum metal sheets can be cut and fabricated with an advanced laser cutting machine.

Thicker Metal Sheets and Metal Materials like Copper, Brass, and Nickel

Sometimes manufacturing companies must work with tougher metal sheets or metal materials like copper, brass, and nickel, and the best laser cutting technology can cut and fabricate these tougher metals.

Other Materials

Laser cutting machines can also readily cut and fabricate non-metal materials such as plastics, wood, fiber, and more. Just be sure and ask your custom cut service provider ahead of time if they can cut and shape the non-metal material required for your manufacturing project

Post-production Processes

Additional fabrication processes like powder coating may also be an option once the metal sheets have been cut.

Regardless of the type of metal sheets, your first step is to choose your desired metal type and thickness, determine the number of custom cut metal parts required, and send the design file of your project to your laser cutting provider.

How Much Does it Cost to Laser Cut Metal Sheets, Like Stainless Steel Sheet Metal?

The answer to how much it costs to custom cut stainless steel sheet metal and other kinds of metal sheets is wholly individualized and dependent on the specifications of the project. Determining factors include the details of the fabrication process (like requiring cutouts, holes, or other custom shapes), the complexity of the project, and the quantity of custom cut metal parts required. (The cost of the metal sheets itself, or other raw materials, obviously also plays a role.)

The best laser cutting service providers will provide instant quoting and detailed estimates on lead times, so you will know exactly how much it will cost to transform metal sheets into custom cut metal parts,

What is the Best Tool to Cut Metal Sheets?

Laser cutting is the best tool for cutting metal sheets, but plasma cutting is also an effective process. Regardless of the type of metal sheets required for a project, like aluminum or stainless steel, advanced plasma and laser cutting technology is more effective than mechanical cutting for metal sheets, simply because of the precision, lack of waste, and ability to create complex cutouts and custom designs.

What is the Best Tool to Cut Stainless Steel Metal Sheets?

Due to their tough and thick nature, stainless steel metal sheets require a high level of power, and high-powered laser cutting or waterjet cutting are the best production methods for them. What is the best tool to cut aluminum metal sheets?

Aluminum metal sheets can present their own challenges, as aluminum is a metal material that is known to be delicate, thin, and highly reflective. The best way to cut and fabricate aluminum metal sheets is with waterjet cutting or advanced laser cutting machines, as these tools have mechanisms in place to avoid damage from the aluminum metal sheets’ reflective nature.

How Does Laser Technology Cut Metal Sheets?

The first step to cutting metal sheets with laser technology is to secure the metal sheets to the workspace in a specially designed facility, to ensure there are no errors in the cutting process due to outside factors, (like debris or the accidental movement of the metal sheets.)

Once the process begins, the laser beam is guided along the surface of the metal sheets, following the exact specifications for the cutouts, shapes, and cuts through computer numerical control guidance. The heat of the laser beam vaporizes the surface of the metal sheets, eliminating any waste or debris with the help of an assist gas. This process is repeated again and again until all metal sheets have been transformed into the desired custom cut metal parts.

What Projects Can Be Created with Metal Sheets and with the Assistance of a Laser Cutting Service Provider?

The sky is the limit when it comes to how metal sheets can be transformed into custom cut parts and products. In addition, when you enlist the services of an experienced laser cutting expert with access to the best technology.

Therefore, are a few factors to consider when considering how to transform metal sheets to an entirely new product and use:

- Type of metal sheets to use for the custom cut parts, (like stainless steel, aluminum, etc.)

- The design specifications of the cutouts

- Post-cutting requirements, like bending, powder coating, or other finishing touches

- Any other details that are essential to the success of project, (like lead times, quantity of the custom metal parts, ordering the raw metal sheets for fabrication, etc.)

Remember that every project that starts with metal sheets should also start with a conversation with an expert in crafting laser cut metal parts. Having the above factors in mind will help expedite the process and make it easier to provide estimates on lead times and cost.

Transform Your Metal Sheets with Steelway Laser Cutting

Steelway Laser Cutting is your best resource for any project that starts with metal sheets, from aluminum to stainless steel, and from copper to brass.

Reach out to our experienced team today to learn more. Start a new partnership that will make the manufacturing of custom cut metal parts faster, easier, and miles more precise. With a resource like Steelway Laser Cutting, you can turn metal sheets into virtually any custom metal part or product while improving efficiency across the board.