The technology and techniques that power laser cutting makes a difference. Therefore, when it comes to the type of technology that drives the laser, CO2 vs. fiber laser cutting machines are a common debate.

However, CO2 lasers and fiber lasers offer a wealth of benefits and advantages over traditional cutting machines that do not use laser systems in the cutting process. CO2 lasers and fiber lasers provide energy efficiency, high cutting speeds, high precision, and huge cost savings, especially when a laser cutting resource and expert like Steelway Laser Cutting is utilized.

Furthermore, while both CO2 lasers and fiber lasers harness laser power for game- changing results, there are some key differences between these two types of laser machines and two laser technologies.

So, if you want to increase productivity and lower the cost of your operations by relying on laser cutters to power your operations, read on to find out the key differences between these two common laser machines.

Table of Contents

How Does a CO2 Laser Work?

What Metals and Materials Can Be Cut with a CO2 Laser Cutter?

What is a Fiber Laser?

Comparing CO2 and Fiber Lasers

Advantages of CO2 Lasers

Advantages of Fiber Lasers

Your Best Choice for CO2 Laser Cutting and Fiber Laser Cutting

What is a CO2 Laser?

A CO2 laser is one of the most common and established types of laser cutters. It was first introduced by Bell Labs in 1964. The CO2 laser is named that because of the method of generating the laser beam itself in the laser cutting process.

How Does a CO2 Laser Work?

CO2 laser cutting works by focusing a high-intensity and infrared laser beam through a series of mirrors before the beam intensifies and is directed onto the material surface. A CO2 laser cutter uses a gas mixture, primarily carbon dioxide, to create this powerful laser beam. Let’s discover the step-by-step process below.

- Creating the gas mixture – A sealed gas tube is present in CO2 laser cutting which has a mixture of carbon dioxide, helium, hydrogen, xenon, and/or nitrogen.

- Power through high voltage – A high voltage reacts with CO2 and gas particles, which increases their energy and produces light.

- Mirrors come into play – The light reflects through the tube, bouncing off a series of optical mirrors, which increases the intensity of the eventual laser beam used for the cutting process.

- Focusing the light and the laser beam – The light passes through a partially reflective mirror and is then redirected through a focus lens that is directed on the material that needs to be laser cut or engraved.

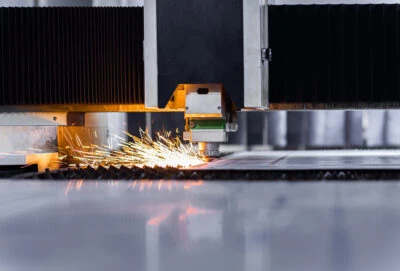

- The power of the laser beam – The ensuing laser beam is directed on the material, causing the sheet metal or other material to vaporize and effectively melt as the specified cuts or engravings are created.

What Are Some Common Uses of CO2 Lasers?

CO2 lasers are ideal for marking, engraving, and laser cutting a wide range of non-metallic materials such as plastics, wood, and even stone. This is why you’ll find CO2 laser cutters in the pharmaceutical and food packaging industries, and the manufacturing sector for the cutting or marking of PVC pipes and building materials.

In the electronics realm, CO2 laser cutters are also used to create parts for mobile communications gadgets, electrical appliances, integrated circuits, and electronic components, cutting both metal and non-metallic materials.

What Metals and Materials Can Be Cut with a CO2 Laser Cutter?

A CO2 laser cutter is a good option to cut materials like:

- acrylic

- wood

- leather

- cardboard

- plastic

- thick materials

- thin materials

- thin gauge metals like stainless steel and carbon steel

- anodized aluminum

- Foam

However, without specialized equipment or advanced technology, a CO2 laser cutter is not as proficient at cutting reflective materials like pure aluminum or copper.

What is a Fiber Laser?

A fiber laser refers to the fiber optic delivery method that brings the intense and amplified light source directly to the cutting head of the laser machine. A fiber laser system is a solid- state laser technology that uses these optical fibers to create a concentrated beam of light.

Fiber laser cutting is a more recent and advanced technology. However, it has grown dramatically in popularity when it comes to laser cutting processes. In recent years, fiber laser sales have surpassed CO2 laser sales due to the advanced fiber laser source that powers the laser cutting process.

How Does a Fiber Laser Work?

Like a CO2 laser, a fiber laser cutter works by directing a laser beam onto metal or other material to melt or vaporize the ensuing cuts or engravings. However, the way in which the laser beam is created is critical to the difference between fiber laser and CO2 laser cutting technology.

- Generating the laser – A diode emits a beam of light that is amplified in a fiber optic cable.

- Light is amplified – The fiber optic cable or fiber core is coated with a rare earth element, like ytterbium. This effectively excites the electrons when they interact with the light. The electrons then release energy in the form of photons, which amplifies the light even further.

- Focusing the light – A lens then focuses this intense light into a beam.

- Reflecting and focusing the beam – The beam is then reflected within a tube, increasing the intensity. Optical mirrors then redirect the beam through a focus lens directed at the material.

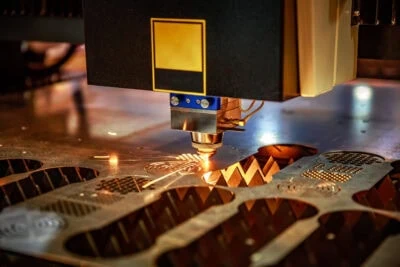

- Cutting the material – The cutting head moves the laser beam as specified to make the ensuing cuts or engravings. As the sheet metal or other material is vaporized with the high-intensity laser beam, an assist gas is sometimes used during the laser cutting process to blow away any remaining molten material.

What Are Some Common Uses of Fiber Lasers?

Fiber laser cutters are utilized in virtually every industry that relies on common metals such as mild steel, stainless steel, and aluminum. (Fiber laser cutters can also be used to cut nonmetals, including plastics or wood, but cutting metals is generally their most popular use.)

Furthermore, fiber lasers have an extremely small focal diameter when it comes to the laser beam. For this reason, they are used for small parts and tiny engravings, like serial numbers, barcodes, and data matrix on metals. Because fiber lasers have low maintenance costs, limited power consumption, and high cutting speeds, manufacturers widely use them for building materials, car and vehicle construction, electronic development, and more.

What Types of Metals and Materials Can Be Cut with a Fiber Laser Cutter?

Fiber laser cutting is an effective way to fabricate all kinds of metals, including stainless steel, mild steel, and even tougher metals like copper and brass. Fiber laser cutting is particularly and notably effective at laser cutting reflective materials, which can be a challenge for comparable types of cutting machines.

It should be noted that when it comes to cutting thicker materials or cutting materials that are more challenging to work with. In addition, the success of laser cutting depends on the laser cutting machine, and the expertise of the team that is powering the fiber laser cutting process.

Comparing CO2 and Fiber Lasers

Whether fiber lasers and CO2 lasers best serve your operations depends on a wide range of factors. These factors include how you want to use laser technology in your current applications and future projects, the materials you need to work with, the optimal cutting speed and precision, and the result of products or parts.

An expert resource in laser cutting technology like Steelway Laser Cutting can help you explore your options to determine the most cost effective but successful laser cutting process for your operations. In the meantime, here is a breakdown of the advantages and disadvantages of CO2 lasers and fiber lasers.

Advantages of CO2 Lasers

- A CO2 laser generally produces a better edge quality or a smoother cut edge on certain types of metals and materials, including plate stainless steel or mild steel.

- A CO2 laser is also considered flexible across a range of laser cutting applications, especially when it comes to non-metal materials and thicker materials.

- A CO2 laser has a high cutting speed, especially for materials that are less than 3/8 inches, although this depends on the technology that powers the laser cutting process.

- CO2 lasers are also predictable and fairly time -tested, since they have existed for decades.

Disadvantages of CO2 Lasers

- A CO2 laser cutting machine is expensive to purchase, operate, and maintain. The upfront cost of an advanced CO2 laser cutter can be $1 million or more, primarily due to optical mirrors and consumables. The power consumption of a CO2 laser cutter is also substantial, and routine maintenance will be required.

- There can be more interruptions in the laser cutting process. Because CO2 laser cutters have multiple moving parts, disruptions are more likely simply because routine maintenance is constant. This means manufacturing processes can be disrupted, with lower operating time.

- CO2 laser cutters are inherently slower than fiber laser cutters, especially when cutting metals like thin mild steel or stainless steel.

Advantages of Fiber Lasers

- Fiber lasers have a lower initial investment cost for manufacturers. However, having access to the best fiber laser cutting technology still requires a huge investment, as well as in-house technicians and state-of-the-art facilities to power the process.

- Fiber laser cutters are noticeably faster than CO2 laser cutters, especially when it comes to thinner materials and metals.

- Fiber lasers can also cut reflective materials like aluminum, which may be challenging for CO2 lasers.

- With lower power consumption, no gas usage for a resonator like in a CO2 laser cutter, and less maintenance, a fiber laser cutter has lower running costs over the long term.

Disadvantages of Fiber Lasers

- When it comes to non-metal materials, CO2 lasers can generally handle a wider range of materials than a fiber laser cutter. However, fiber lasers tend to have an edge when it comes to metals. Again, this is very dependent on the technology of the laser cutter itself.

- While fiber lasers can cut metal materials at a high cutting speed, the speed may be reduced depending on the intricacy of the design.

- Fiber lasers may not be as adept at cutting thicker materials.

- Fiber lasers require very strict adherence to safety guidelines, as the technology that powers fiber lasers can cause eye damage if the laser cutting machine is not used correctly.

- Fiber laser cutters have a lower initial cost than a powerful CO2 laser cutter, but for large manufacturing operations, expect to invest around $500,000 or more.

- Fiber lasers consume less power, and they are generally considered more environmentally friendly.

When it Comes to CO2 Laser Cuttingand Fiber Laser Cutting, Technology and Expertise Make a Difference

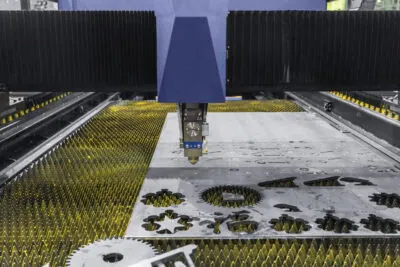

Both CO2 laser cutting and fiber laser cutting are processes that are routinely used in manufacturing industries across all sectors. Both laser technologies offer high precision, fast cutting speeds, and exceptional results compared to traditional cutting methods without laser cutting technology.

This is especially true when computer numerical control (CNC) is involved. A CNC laser cutting machine virtually eliminates human intervention, and the potential for human error. Instead, cutting instructions are fed to the laser cutter, and the laser cutting machine does the rest, following intricate designs and patterns that can be replicated again and again without interruption.

Steelway Laser Cutting is Your Best Choice for CO2 Laser Cutting and Fiber Laser Cutting

We have been in business for decades, meeting and exceeding the expectations of all clients. Our laser cutting processes are powered by the most advanced technology, the best equipment, the most experienced technicians, and state-of-the-art facilities.

Discover the financial gains you can enjoy when you partner with laser cutting experts for your laser cutting projects.

From manufacturing operations to new ventures and artistic projects, we will power your laser cutting needs with the best technology and best service possible to ensure that every laser cutting project is perfectly executed.

Reach out to us today to start the conversation. Discover how having access to the best laser cutting technology available – CO2 or fiber laser – makes a world of difference.

Ready to enhance your project with precision laser cutting?

Contact Steelway Laser Cutting today to see your designs come to life!