Some metals are inherently more difficult to cut than others. Thin aluminum can be challenging due to its delicate nature and reflective properties, while tougher metals like brass and copper can be hard to fabricate with traditional cutting methods. Therefore, laser cutting thick steel is one of the most common metals and most challenging when it comes to the laser cutting process.

However, manipulating thick steel can be miles easier and more effective when advanced laser cutting technology is utilized in the cutting process.

This is why many companies of all sizes turn to an expert laser cutting service provider. Laser cutting thick steel can be difficult to tackle in house without vast financial and personnel resources.

An advanced cutting machine is certainly required, so it is a specially designed facility with a team of expert technicians to guide the cutting process. However, outsourcing these operations is a surprisingly cost-saving and time-saving way to produce thick steel parts and products without sacrificing quality.

Let’s discover more about the challenges and solutions for laser cutting thick steel.

Why is Thick Steel Difficult to Cut?

Thick steel is difficult to cut for a range of reasons, which include the following:

- Material strength – Thick steel is inherently stronger and more durable than thinner steel (as it becomes stronger as it is rolled or formed), which is why it’s a common material in a range of long-lasting parts and products. However, these same qualities that make it tough also make it more difficult to cut without the right tools and expertise.

- Possibility of debris – Debris is a common issue when using traditional methods to cut steel (like a saw or other machinery). Debris can infiltrate the cutting mechanism and the steel sheet itself, making cuts imprecise and causing damage to the cutting machine.

- Precision concerns – Without the right tools and techniques, it’s very easy for errors to occur. Creating precise cuts in steel is a common challenge, especially when it comes to more basic or older cutting methods.

How Does the Laser Cutting Process for Thick Steel Work?

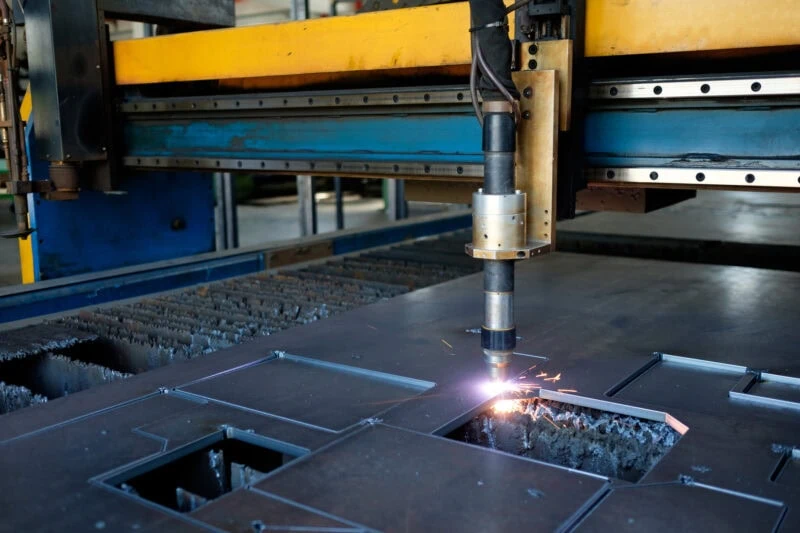

Laser cutting is distinctive because the process is both high- powered and highly accurate. When it comes to laser cutting sheets of thick steel, an initial computer-aided design (CAD) is created that outlines the specifications for all the cuts required.

This CAD file is linked to the computer numerical control (CNC) laser cutting machine. This means that the ensuing cutting process is automated, with no human needed to guide the direction of the laser beam itself.

When it’s time to cut, the laser beam focuses on the designated area of the sheet metal, with the heat of the laser beam vaporizing the thick steel metal sheet to create the desired cuts. Because of the intensity and heat of the laser beam, the laser beam effectively melts the metal, and an assist gas may also be used in the process to blow away any molten material as needed. Generally, for stainless steel or aluminum, nitrogen is used to blow away the molten metal.

The process is repeated for every steel part or product until all units within a production run are complete. Since this high level of precision and automation is part of the process from start to finish, there are no errors or deviations between one part and the next. Furthermore, companies can expect perfect results for every steel project they require.

Steelway Laser Cutting can provide exceptional laser cutting (Philadelphia area and beyond) while improving your production operations from the ground up.

How Thick of Steel Can a Laser Cut?

Laser cutting machines are the best option for thick steel. However, the maximum thickness for laser cutting steel highly depends on the laser cutting machine.

Popular laser cutting machines commonly used in the process include CO2 laser cutters, fiber laser cutters, and even plasma laser cutters. Each machine can be effective for thick steel laser cutting projects.

At Steelway Laser Cutting, we use first-class and highly advanced machines from the TruLaser series 1000 that can cut a wide variety of materials – including thick steel – in virtually any shape or design. Our machinery and facilities can effectively facilitate high-volume orders of 1000 or more units per project. Additionally, we can cut copper, bronze, aluminum, stainless steel, galvanneal, and regular hot-rolled steel.

Out steel cutting capabilities are as follows:

- Electrogalvanized Mild Steel: .508mm – 3.048mm (Inch Conversion: .02in – .12in)

- Mild Steel, Hot Galvanized: .508mm – 4.064mm (Inch Conversion: .02in – .16in)

- Mild Steel w/Oxidized Surfaces: 2.032mm – 20.07mm (Inch Conversion: .08in – .79in)

- Stainless Steel Coated: .508mm – 4.064mm (Inch Conversion: .02in – .16in_

- Stainless Steel: .508mm – 14.99mm (Inch Conversion: .02in – .59in)

- Mild Steel: .508mm – 20.07mm (Inch Conversion: .02in – .79in)

Remember that steel is just one of the materials we work with on a regular basis. We can also help with any metal cutting project your company and manufacturing operations require.

Why Are Laser Cutting Service Providers the Best Option for Cutting Thick Steel?

- Cost – Laser cutting services are much more affordable than purchasing, maintaining, and operating advanced laser cutting machines in-house.

- Timeliness – Even with shipping involved, laser cutting steel is a faster and automated process that can be repeated without human intervention, until the project is complete

- Accuracy and results – Laser cutting ensures that every part or product is perfectly cut to specifications due to the precision of the laser cutting machine and the automation that powers the process. As such, companies will have fewer errors (and will save money and resources) by ensuring every metal cut is precisely right.

- Freedom of design – Even the most intricate designs can be created with a laser cutting machine without devising from one part or product to the next.

Learn More About Laser Cutting Thick Steel from our Experts at Steelway Laser Cutting

With decades of experience, we have handled every type of metal cutting project imaginable, including complex laser cutting for thick steel.

Reach out to our professional and friendly team today with all your questions. Launch a new and effective way to streamline your manufacturing operations while ensuring cost savings and better results.

Steelway Laser Cutting offers a vast range of laser cutting services near Philadelphia and beyond.