Stainless steel is one of the most widely used metals in various industries. However, cutting stainless steel requires both expertise and highly advanced technology to achieve perfect cuts again and again.

A time-tested stainless steel laser cutting service with access to the best technicians and technology is the optimal resource for perfecting laser cut stainless steel, regardless of the scope, size, or details of any project.

In the meantime, it’s helpful to understand the basics of the different properties and techniques that will determine the best practices for cutting stainless steel.

Understanding Stainless Steel – Composition and Types

When producing stainless steel, several different materials can be used to achieve different results and different properties. These materials include (but are not limited to), the following:

- Carbon – A higher carbon content in stainless steel makes the metal more durable and longer lasting than other alloys, which is why it’s a popular type of stainless steel for cooking implements and high-quality utensils

- Nickel – Nickel can improve stainless steel’s formability and ability to be welded, making the metal more corrosion-resistant. As a result, it allows stainless steel to be more versatile for more complex parts and products.

- Chromium – Chromium makes stainless steel more resistant to corrosion, tarnishing, and stains. This is why you will see this type of stainless steel in several outdoor structures, including buildings and bridges.

The Three Main Types of Stainless Steel

There are thousands of different types of stainless steel alloys that can be produced, but most of these will fall into three distinct categories.

- Austenitic stainless steel – Austenitic stainless steel has two main components. It includes a lot of chromium in its initial production, and second, the metal products and parts tend to be inherently non-magnetic (although this can be altered with a post-production cold- forming process.) Austenitic stainless steel is arguably the most common type of stainless steel alloy.

- Ferritic stainless steel – Ferritic stainless steel is the second most common type of stainless steel alloy, as it tends to be less expensive than other types due to its low nickel content.

- Martensitic Stainless Steel – Not as common as austenitic stainless steel and ferritic stainless steel, this type of metal is used in manufacturing operations where a high tensile strength or impact resistance is needed.

Cutting Techniques for Stainless Steel

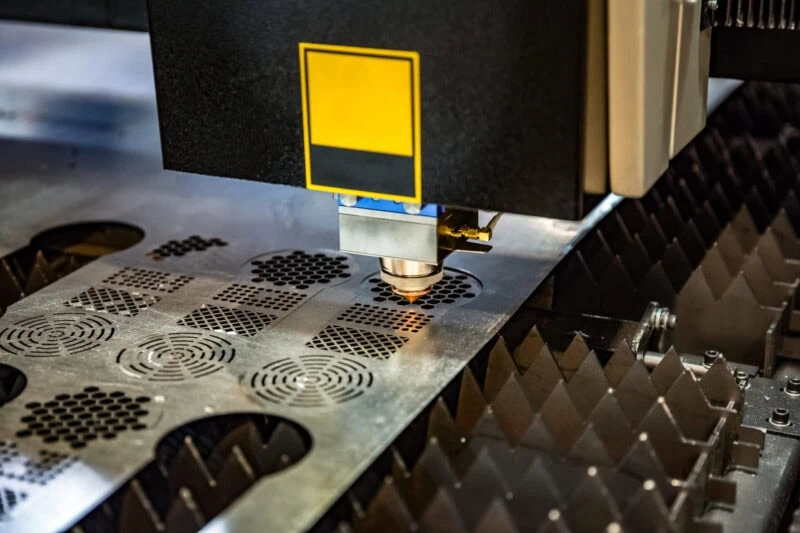

Regardless of the exact type and properties of a stainless steel alloy, CNC laser cutting is considered the best method for fabricating stainless steel for various uses.

Certainly, you can use more traditional and simple tools like tin snips, a circular saw, power shears, or a jigsaw. However, these methods are best reserved for basic at-home projects, not commercial or mass-production manufacturing operations.

Even more unique artistic endeavors, like outdoor accents or home décor items, can benefit from CNC cutting services, due to their precision, attention to detail, and ability to follow detailed blueprints to the letter.

How to Laser Cut Stainless Steel

When it comes to using advanced technology to cut stainless steel, two strong options to consider are CNC plasma cutting and laser cutting.

Both plasma cutting and laser cutting are thermal cutting methods that use intense heat to accurately cut stainless steel and other metals, but there are some subtle differences between the two.

- Accuracy – Laser cutters are generally more accurate than plasma cutters, although the difference is minimal. For example, laser cutters may have a tolerance of .002 inches, while plasma cutters may have a tolerance of .004 inches.

- Thickness – Plasma cutters can generally cut thicker metals than laser cutters, although, again, this depends on the advanced cutting machine powering the process.

- Materials – Both laser cutters and plasma cutters can fabricate stainless steel of all varieties and other conductive metals. However, laser cutters are a better fit for non-metal materials like plastic or wood.

The Stainless Steel Cutting Process

Step 1 – Choosing the right CNC cutting services provider.

Your choice of CNC cutting services provider will determine the success of your stainless steel projects and/or manufacturing needs. Make sure you partner with a company that has decades of history, access to the best technology, and which has a sterling reputation for projects of all varieties.

Step 2- Creating the design

Advanced laser cutting services providers use computer-aided designs fed to a computer numerical control (CNC) plasma cutting machine or laser cutting machine to achieve the best results. With technology guiding the way, the cutting machine can follow the specifications of every detail and repeat the process repeatedly without any deviation from one part or product to the next.

Because of this steadfast process, using an advanced plasma and/or laser cutter is the best option for manufacturing companies. Because human involvement is limited and the cuts are so precise, there is no excess waste due to incorrect cuts, and more sheet metal raw material can be used in every project.

Step 3 – Post-production considerations

Depending on the technology and cutting machine driving the process, there may be some post-cutting measures required to ensure a smooth and clean finish.

For example, you may want to apply varying techniques to remove any burrs or add powder coating to make the end-result part or product even more resistant to corrosion and/or aesthetically attractive. Powder coating comes in a range of colors and is known for adding an extra layer of strength to any metal, including stainless steel.

Your CNC cutting services provider can guide the way when it comes to post-cut handling and processing and the optimal ways to ensure the strongest and best end results possible.

Discover the Benefits of Partnering with a CNC Cutting Services Provider for Your Business

Connect with us today to start a conversation about the unique uses of stainless steel.

At Steelway Laser Cutting we can help your business create the parts and products you require in the most timely and cost-effective manner possible.

With an expert behind the scenes, you can drive your stainless steel cutting operations to new heights of productivity and efficiency, regardless of how your needs evolve and advance over time.