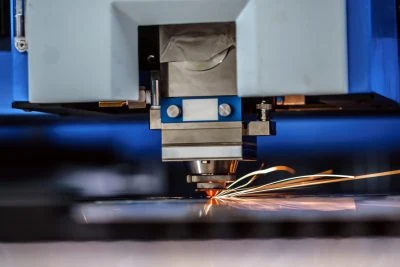

When it comes to cutting sheet metal, no method offers the high precision, high speed, and clean cut produced by a laser cutting machine. Prominent in manufacturing needs across all industries, a high-powered laser cutting machine can revolutionize the production capacity of a company, regardless of the metals or materials required for the end-result cut parts.

When using the power of light, heat, and a focused laser beam, laser cutting services can provide the utmost levels of efficiency in different types of manufacturing operations while keeping the overall price and shipping costs minimal for the ensuing cut parts.

However, to take advantage of sheet metal laser cutting services, it’s essential to understand the process. Also, it’s good to understand the many materials or metal parts that can benefit from laser cutting, and how laser metal fabrication works from the ground up.

Read on to uncover the fundamentals of sheet metal laser cutting and remember that when it comes to laser cutting services, you always have a resource and a partner with Steelway Laser Cutting.

Table of Contents

What Types of Metals and Materials Can be Laser Cut with a Laser Cutting Machine?

How Does the Laser Cutting Process Work?

A Case Study – The Fiber Laser

The Advantages of Laser Metal Cutting

Learn More About Laser Cutting with Steelway Laser Cutting

What is Laser Cutting?

Laser cutting was first introduced in the second half of the 20th century for very specific cutting jobs required in highly specialized manufacturing industries, like diamond cutting or cutting metal parts for aerospace operations. While the first laser cutters only addressed specific types of metal, today, many materials can undergo the laser cutting process.

As technology grew in the late 1980s and 1990s, so did the demand for laser cutting machines in multiple manufacturing industries. New laser cutting machines were introduced to make the process more efficient and precise.

Laser machines like fiber lasers and C02 lasers have made laser cutting more accessible and dynamic. Today, several metal parts (and other materials) can be efficiently cut with the best laser cutting equipment on the market.

What Types of Metals and Materials Can be Laser Cut with a Laser Cutting Machine?

The sky is the limit when it comes to what type of sheet metals or other materials can be fabricated adequately with a top-notch laser cutting machine.

Here is a sample of just a few different metals and materials that can benefit from the speed and power of a laser cutter.

Galvanized steel

Galvanized steel is a typical sheet metal with numerous applications, specifically in construction and car manufacturing. A zinc-iron alloy product where the base metal is coated through a heat process, galvanized steel sheets can easily be laser cut with an effective and powerful laser, like high power fiber lasers.

Carbon steel

Carbon steel is another metal that often comes in sheet form, and carbon steel is a type of steel with multiple uses. Additionally, carbon steel is found in buildings and bridges, metal steel parts like gears and pipes, and metal household appliances like refrigerators or washing machines. Like stainless steel, carbon steel can be cut or fabricated by multiple types of lasers and laser cutting machine methods, like the flame cutting process, which can cut thick metal sheets of mild or carbon steel plate with thicknesses over 30 millimeters and at high speeds.

Titanium

Titanium is a complex, shiny, and strong metal that is as tough as steel but much less dense. Therefore, it’s a popular metal in aircraft, spacecraft, and missiles due to its inherent ability to withstand heat. Like other types of sheet metal, laser metal cutting is a solid way to create highly precise titanium metal parts at a high rate of speed.

Aluminum

Light and pliable aluminum is a metal used in all industries. Aluminum is found in many metal parts and products that people use every day, including cars, window frames, other household metal parts, airplane parts, and much more. The key to cutting aluminum is to have a laser cutting machine that utilizes a highly focused laser beam to melt material efficiently and with high precision. Because aluminum is one of the more delicate metals, laser cutting metal sheets of aluminum is a process that an expert laser cutting service provide should handle.

Brass

On the opposite side of the metal spectrum are tougher metals like brass. Brass is the opposite of thin metal sheets like aluminum or certain types of mild steel, as brass is a tough material designed for long-term use. Corrosion resistant, brass is commonly found in products and cut parts designed to last, like brass locks, hinges, gears, plumbing materials, and other metal materials found indoors and outdoors. With brass, a high-powered laser cutting machine is required to melt material efficiently in the heat affected zone, to create the desired metal parts.

Copper

Like brass, copper is another tough metal that benefits from the power and efficiency of a high-energy laser cutting machine. Copper is used as a conductor of heat and electricity, as a building material, and as an element in different metals and alloys, ranging from metals found in jewelry to the metal in everyday coins. Because of copper’s demanding nature, cutting copper plates or other copper materials requires a laser cutter with a lot of power to create cut parts with a smooth edge that meets the exact specifications.

Other Metals and Materials that Can Benefit from Laser Cutting Services

Multiple metals and other materials can benefit from a laser cutting system (provided the best laser cutting equipment is used), such as nickel, wood, fiber, plastics, and much more.

Your laser cutting services provider can provide detailed information on the right process for your distinctive manufacturing jobs, which includes an estimated price (instantly provided), shipping timeframe, manufacturing requirements, and more.

How Does the Laser Cutting Process Work?

While the exact process for cutting sheet metal may vary based on the material or metal sheet that needs to be fabricated (as well as the precise type of laser cutter involved) the laser cutting process generally involves the following.

Creating the Metal Part Specifications and Design

First, the design for the cut parts is created with computer-aided design software, which is typically an online platform designed to develop detailed specifications to guide the laser beam. Online laser cutting is becoming the norm in our modern era. Therefore, online laser cutting begins with sending the computer aided design for the metal sheets to your laser cutting services provider. From there, the laser cutting services provider will create a final price estimate for the project and typically provide a manufacturing timeline to ensure all cut parts are created at a top rate of speed.

The computer-aided design software is then fed to the laser cutter, and the process of creating every metal part is automated thanks to computer numerical control guidance.

With the specifications in mind (like length, depth of the laser cut, and other details), the laser beam is then focused onto a localized area of the metal sheet to create the ensuing cut parts. Because of the extreme heat of the focused laser beam, the metal material is melted away without leaving behind any debris. This process results in high-precision cuts and a smooth edge for every metal part. This process is repeated for every cut metal part until the manufacturing project is complete.

A Case Study – The Fiber Laser

When it comes to cutting sheet metal, multiple laser cutting machines and equipment can tackle distinctive jobs. For example, plasma cutting is a popular process for a wide array of metal sheets, like stainless steel, mild steel, or aluminum. Additionally, C02 laser cutting machines can have varying price points, and various levels of power, precision, and efficiency.

One of the most common metal laser cutters for a range of varying metals are fiber lasers or fiber laser cutting machines. The fiber laser cutting system is known for its speed and precision, and typically, fiber lasers are utilized via the following process.

- In a fiber laser cutting machine, banks of diodes are used to create a laser beam that is channeled and intensified through a fiber-optic cable.

- To create focused light in a single direction and effectively create the laser beam, the fiber cables in fiber lasers use two essential components: the fiber core and the cladding. The core is where light travels, while the cladding is the material that surrounds the core, providing internal reflection.

- This light enters the laser cavity, leading to a high energy and highly focused laser beam. The laser beam is directed onto the metal sheet or other material with intense heat to create the desired cut parts.

Fiber lasers are some of the best machines for cutting metal and materials at high rates of speed, and fiber laser cutting machines are popular with manufacturing companies across the board. Like other types of modern metal laser cutters, fiber lasers may have too high of a price tag to purchase in house. Instead, many manufacturers use metal laser cutting services providers to access the best metal laser cutting systems without exceeding a desired price threshold.

When determining the best system for metal laser cutting, it’s essential to consult with a metal laser cutting expert. Regardless of the sheet metals used, or the exact specs for the metal parts, an expert in laser metal cutting will have access to the best machines and can conduct the manufacturing operations from start to finish, at a square and pre-determined price.

The Advantages of Laser Metal Cutting

There are several features that give laser cutting machines substantial advantages over traditional equipment and machines used to cut metal parts. Whether you are working with steel, aluminum, or other materials, here is a sample of the advantages your manufacturing operations will enjoy when you utilize the power of laser cutters for cutting sheet metal.

Laser cutters can cut steel and other metals at a high rate of speed

When it comes to speed, the power of a metal laser cutting machine is unmatched. Because every laser cut can be repeated without interruption, a metal laser cutting machine can run interrupted until every metal part has been carefully crafted. Even when shipping is involved through an outsourced laser cutting services provider, metal parts can typically be laser cut within days at the most, creating a reliable process and that takes the pressure from meeting strict deadlines.

Metal laser cutters have a high rate of precision

Regardless of the metal or material used (like mild steel, carbon steel, galvanized steel, or other metal), every sheet metal is fabricated with the highest level of precision. The heat and high energy of lasers effectively vaporize localized areas of sheet metals, creating a laser cut that perfectly aligns with specifications. The laser cut width can typically be less than 0.001 inch. On the other hand, the laser cut dimensional accuracy can hover at 0.0005 inches or less, which means that laser cutting sheet metal can result in the most intricate metal parts imaginable. This is why sheet metal laser cutting is popular in manufacturing sectors requiring small metal parts, like the electronics and medical device industries. Simply put, when it comes to precision, there is no equal to the exacting nature of a laser cut.

Sheet metal laser cutting is a smooth process from start to finish

So, first the laser cut is created in a workpiece of sheet metal, such as steel. Then metal laser cutting machine follows the exact specifications, again and again, for every sheet metal workpiece that follows. A modern sheet metal laser cutting machine requires no human intervention or maintenance during the laser metal cutting process, so manufacturers can rest assured that every laser cut part is exact and easily duplicated, no matter how complicated the overall plans for sheet metal laser cutting are.

Sheet metal laser cutting can be conducted at an attractive price

Even when outsourced, sheet metal laser cutting is a process that can be performed at a low cost for manufacturers who must stick within a budget. The key is to use a sheet metal laser cutting services provider that can address a wide array of projects (from steel sheet metal to more unusual materials like wood or fiber) with precision and efficiency at every step. The best sheet metal laser cutting providers have highly advanced facilities, laser cut technicians who specialize in laser metal cutting, and the best laser cutting machines on the market to provide exceptional results.

Sheet metal laser cutting is an environmentally friendly process

One of the advantages of laser metal cutting is that the energy and heat used to power the lasers are environmentally friendly. In addition to reducing the overall cost due to a lack of excess waste and debris for every piece of steel or other sheet metal, the energy required to power each laser cut is minimal. As a result, manufacturers will enjoy a lower price for sheet metal cutting, as the process is highly productive with minimal energy or extra effort.

Ready to Learn More About Laser Metal Cutting Services? Connect with Steelway Laser Cutting

When it comes to metal cutting, no method can compare in terms of price, efficiency, and precision to a laser metal cutting machine.

Laser metal cutting is a highly specialized process requiring an expert for every laser cut. Therefore, a laser metal cutting services provider is your best resource when it comes to taking advantage of the many benefits of the laser metal cutting process.

Regardless of whether your business routinely works with mild steel, galvanized steel, carbon steel, aluminum, copper, brass, or other materials, Steelway Laser Cutting can help. With the best laser metal cutting machines available and the expert and experienced team required to conduct every laser cut perfectly, Steelway is your ultimate guide for laser metal cutting in all forms.