Manufacturers and small businesses have many options when it comes to the best methods for fabricating metals and other materials, and one of the most advanced options is fiber lasers.

Fiber lasers are exceptionally powerful and accurate for laser cutting, laser marking, laser welding, laser engraving, laser texturing, and other material processing needs. Additionally, many consider fiber lasers to be some of the most advanced and best laser machines in the world.

Understanding the laser power achieved with a fiber laser starts with understanding how fiber lasers work. Read on to uncover the fundamentals of modern fiber laser machines.

Table of Contents

What are the Main Types of Fiber Lasers?

How Does a Fiber Laser Work?

The Step-by-Step Process of How a Fiber Laser Works

Which Laser Parameters are Used When Describing Fiber Lasers?

How are Fiber Lasers Designed?

The Best Fiber Laser Technology with Steelway Laser Cutting

What is a Fiber Laser?

Fiber lasers are solid state lasers that use optical fibers as their optical gain medium (also called an active laser medium.) An optical fiber made from silica glass or phosphate absorbs the unprocessed light that stems from the pump laser diodes and then converts it to a concentrated laser beam of a particular wavelength. The optical fiber cable is doped, which means incorporating a rare earth element into the fiber cable in order to make the process possible.

When it comes to the wavelength in the resulting laser beam, different doping substances inherently produce different wavelengths. Common examples include ytterbium doped fiber lasers, thulium-doped fiber lasers, dysprosium doped fiber lasers, and holmium doped fiber lasers.

Because of this wide range of possible wavelengths, fiber lasers are ideal for a wide range of applications, from laser cutting to laser welding to laser marking. In addition, high- power fiber lasers are extremely energy efficient than their laser machine counterparts. For example, a fiber laser machine is up to 50% more efficient than a C02 laser machine.

What are the Main Types of Fiber Lasers?

Fiber lasers are classified based on the source of the laser beam (I.e., thulium-doped, erbium-doped, or ytterbium-doped), the laser mode, the mode of operations (multi-mode or single mode), and the laser power.

Regardless of these individualized variations, fiber lasers are valuable and powerful because of their highly efficient gain medium, their robust optical cavity, and a smart feedback loop through fiber Bragg gratings. (A fiber Bragg grating is made by laterally exposing the core of a single-mode fiber to a periodic pattern of intense laser light.)

How Does a Fiber Laser Work?

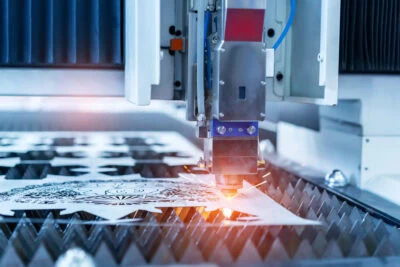

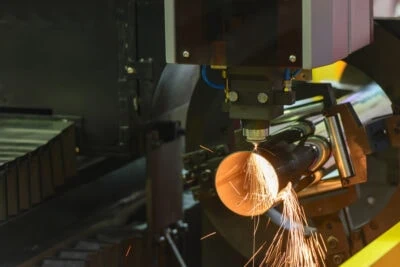

A fiber laser creates a sharp beam of laser light that can fabricate and cut through even the toughest metals and materials.

Fiber laser technology differs from other, commonly used laser machines because of the source, and the way the laser beam energy is delivered and focused onto the workpiece. A laser beam system consists of three basic components – gain medium, optical pump, and mirror array.

The optical pump produces electrical energy, which is converted into photons within the active gain medium. (The gain medium is the substance where the photons are both produced and amplified.)

Visible laser light is repeatedly reflected by the multiple mirrors, which creates the formation of a focused laser light. By controlling the electromagnetic wavelengths, the process enables laser beams to focus on the workpiece with outstanding accuracy and efficiency.

The Step-by-Step Process of How a Fiber Laser Works

Step 1. Creating the Light for Fiber Laser Beams

In this step, electricity is converted by laser diodes into photons (or light), which are then injected into the fiber optic. (These laser diodes are also sometimes referred to as the “pump source” or “pump diodes.”) The laser diodes use two oppositely charged semiconductors to produce the laser diode light or pump light.

The positively charged electrodes seek out additional electrons, while the negatively charged electrodes have extra or spare electrons. To neutralize the charges, the free electron has to jump between electrodes. During this process, the electron releases a photon, and the number of photons will rapidly increase as the semiconductors are subjected to current.

Step 2. Pump Light Through the Fiber Optic Cables

The fiber core and the cladding are the two instrumental parts that fiber optics cables use in order to concentrate light in a specified direction and produce the laser beam. The light travels through the fiber’s core, which is the sole part of the fiber optic cable that contains a rare-earth metal and is made of silica glass.

Step 3. Light Amplification in the Laser Cavity

When the laser diode light reaches the doped fiber, it interacts with the rare earth atoms, raising the electrons’ energy levels. This results in a population inversion, a requirement for producing laser beams.

When a gain medium is in a state or condition referred to as population inversion, more electrons than usual are in an excited state as a result. The electrons will release photons when they drop back down to lower energy levels, but some of these electrons can only produce photons with a specific or certain wavelength. This is the “stimulated emission” part of the acronym LASER (Light Amplification by Stimulated Emission of Radiation).

The incoming light from the pump diodes re-excites these electrons as they return to their original relaxed condition. A constant stream of laser light is the result of the process, when a balance between the stimulated and relaxed electrons is eventually reached.

Step 4. Creating a Laser Light or a Targeted Wavelength

The doping component of the laser cavity has an impact on the fiber optic’s wavelength. This is important since different laser applications require different wavelengths to work. Different doping substances will create different wavelengths, and every type of fiber laser produces a specific wavelength and nothing else.

Step 5. Shaping the Laser Light

Different parts of the fiber laser system, such as the lenses and expanders for laser beams, can be used to shape the laser beam as needed. Lenses are carefully chosen for different kinds of applications. For example, laser texturing uses short focal lenses to concentrate more energy on a smaller area.

Step 6. Releasing the Laser Light

Once the best lens for the job is in place, the laser beam is released to perform the work at hand. These fiber laser beams can then be used to cut, weld, engrave and much more (like laser cleaning or laser texturing applications)

Which Laser Parameters are Used When Describing Fiber Lasers?

In essence, the parameters for fiber lasers will differ between varying laser modes. Laser power, the beam diameter, and the welding or cutting speed are laser parameters associated with continuous wave lasers. (Continuous wave fiber lasers have nominally continuous output power over a set interval of time. This means that key parameters for laser beams, like output power and intensity, are constant for the laser beam’s duration.)

Meanwhile, the laser parameters used for pulsed lasers or pulsed fiber lasers are pulse duration, beam diameter, energy, and the rate of repetition. Other parameters commonly found in fiber lasers include wavelength, laser power, and beam quality.

How are Fiber Lasers Designed?

Fiber lasers are designed using a wide array of specific criteria. The different attributes that make up the overall laser design are as follows.

The Laser Cavity in Fiber Lasers

The laser cavity is where the laser medium or gain medium is housed, and it has multiple optical elements to increase the overall strength and power of the laser beam.

The Fusion Splicing Technique in Fiber Lasers

Fusion splicing is the process of slicing fiber optic cables together so that the light passes through them uninterrupted. When properly designed, the fiber laser generates more energy and efficiency as a result.

The Laser Diodes in Fiber Lasers

The laser diodes are compact and practical semiconductors that change electrical energy into laser light. These elements form the proper brightness and spectrum in order to pump the doped fiber. The rare earth ions that are embedded in the doped fiber interact and get excited by the laser beams, which are produced by the laser diode pump sources. The ability of a doping substance to absorb light from these pump lasers plays a role in their selection.

The Dielectric Mirror in Fiber Lasers

Dielectric Mirrors are mirrors that are made of multiple reflective materials. This makes the mirror more reflective than traditional mirrors made from a single material, and fiber lasers use these dielectric mirrors to further increase the gain of the laser output.

The Distributed Feedback Lasers in Fiber Lasers

A distributed feedback laser has special qualities. It uses a gain medium and a periodic structure as its entire laser resonator, acting as a distributed reflector in the laser’s operating wavelength. Most distributed feedback lasers use a sole resonator mode and are fiber or semiconductor lasers.

The Double-Clad Fibers in Fiber Lasers

Double-clad fiber is most commonly found in high-power fiber laser machines. The core of a double-clad fiber is doped with rare earth elements, and the desired laser beam properties are provided by a single-mode fiber.

The Diffraction-Limited Beam Power of Fiber Lasers

The diffraction-limited beam has the highest brightness for any given optical power, and the term “diffraction limited” refers to a laser beam that is only limited by the unavoidable diffraction when it comes to its ability to focus on a small point. As such, this laser has inherently better beam quality.

The Stimulated Brillouin Scattering of Fiber Lasers

When the narrow-band optical signals are amplified in a fiber amplifier or transmitted through a passer fiber, stimulated Brillouin scattering (or simply SBS) occurs.

The Large Effective Mode Area in Fiber Lasers

The effective mode area is the area that a fiber mode or waveguide covers in the transverse dimensions. Optical fibers with large mode areas are helpful for various applications but imply reduced optical intensities for a given optical power. However, these fiber lasers have stronger damage thresholds and fewer nonlinear effects. However, because of this, they can be utilized to amplify strong pulse or single-frequency signals in fiber amplifiers.

The Saturable Absorber in Fiber Lasers

A saturable absorber is an optical component that that has a specific absorption loss for light which decreases at higher optical intensities. Saturable absorbers can be used in optimal signal processing and nonlinear filtering outside the laser resonators for various reasons, such as cleaning up pulse forms.

The Semiconductor Saturable-Absorber Mirrors in Fiber Lasers

A semiconductor saturable-absorber mirror is a specific type of saturable absorber that is used in mode-locking lasers. It’s essentially a mirror structure that uses semiconductors as built-in saturable absorber media. In addition, a semiconductor saturable-absorber mirror is frequently utilized for laser passive mode locking, especially when it comes to solid-state bulk and fiber lasers.

The Multi-Wavelength of Fiber Lasers

Fiber lasers can serve as multi-wavelength optical sources. They also emit a light at multiple, well-defined wavelengths at the same time.

Fiber Laser vs CO2 Laser

The primary difference between fiber lasers and C02 lasers is the source where the laser beam is created.

A fiber laser source is silica glass mixed with rare earth elements,. On the other hand, the CO2 laser source is a mixture of different gases with C02 being the primary component.

Both high-power lasers generate precise and powerful laser beams, but many experts believe that fiber lasers have an edge when it comes to speed, precision, and energy efficiency.

In fact, one of the only possible drawbacks of fiber lasers is the cost.

Fiber laser technology is so advanced. Its initial up-front costs (as well as the years of maintenance and expertise required) make it one of the most expensive technologies for laser cleaning, cutting, texturing, engraving, welding, and more.

Access the Best Fiber Laser Technology with Steelway Laser Cutting

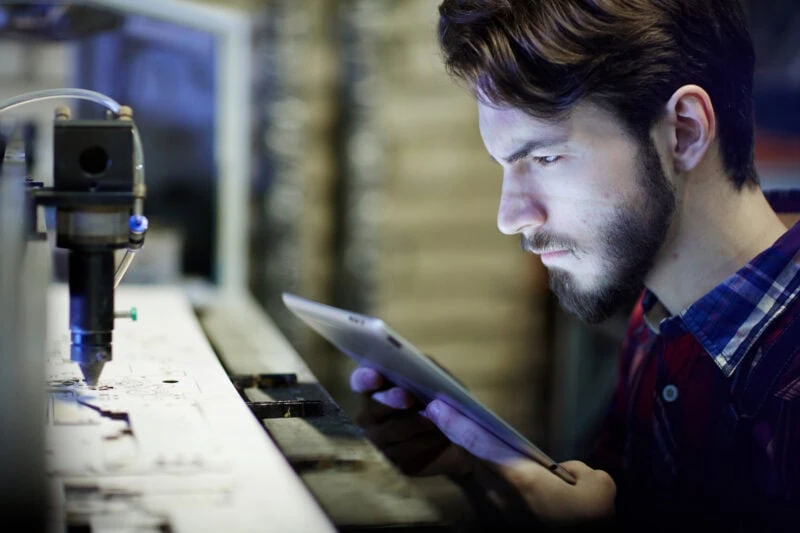

Most businesses do not have the budget or expertise to purchase, maintain, and operate fiber laser machines in-house. Therefore, that’s why they partner with a trusted fiber laser provider like Steelway Laser Cutting.

At Steelway, we can provide exceptional results for all metal fabrication projects, from laser cutting to laser engraving. We also have decades of experience helping clients across all industries with projects of all sizes and different levels of detail.

We’re happy to put our time-tested expertise for your manufacturing and fabrication needs. Reach out to use today to start the discussion. We’ll work together to ensure that you have continual access to the best laser technology available – including fiber lasers.