Manufacturers, from small businesses to large corporations, can encounter challenges when trying to perform in-house cutting of their steel, metals, wood, and other materials. The cost to perform intricate cutting by purchasing a cutting machine can be prohibitive. Therefore, the ensuing cuts, engraving, and other machine-generated actions may not be up to a company’s high standards. However, there is a solution for manufacturers who need to cut, engrave, or shape materials to absolutely precise measurements – outsourcing to a production-oriented company that performs CNC laser cutting.

Laser cutting machines for cutting or engraving wood, metals, and everything in between have been around for decades, but CNC laser machines take this technology to the next level. They are powered by software that outlines the most minute details. CNC laser cutting machines are a much more powerful tool than other machines that may result in excess waste or incorrect engravings or cuts.

What is a CNC Laser Cutting Machine?

How Does a CNC Cutting Machine Work?

The CNC Machine Design Process

The CNC Laser Cutting Machine Process

The Benefits of Using a CNC Laser Cutting Machine

What is Laser Engraving?

Partner with Steelway Laser Cutting

Choosing the Right Laser Cutting Machine

Manufacturing companies rely on precise cuts or engraving to create perfectly designed parts that fit together to form a full, top-quality product. Therefore, with a CNC laser cutting machine as a backbone resource, small businesses can achieve this goal while minimizing.

Curious about how your company could work with a CNC laser cutting machine provider? The first step is to reach out to Steelway Laser Cutting for a conversation about our laser cutting system and operations. You will understand how we can best benefit your manufacturing needs.

In the meantime, however, take a moment to familiarize yourself with the mechanics of CNC cutting machines. Additionally, you will learn how they differ in terms of cost, technology, materials, support, and other specifics that create the products and materials you need.

What is a CNC Laser Cutting Machine?

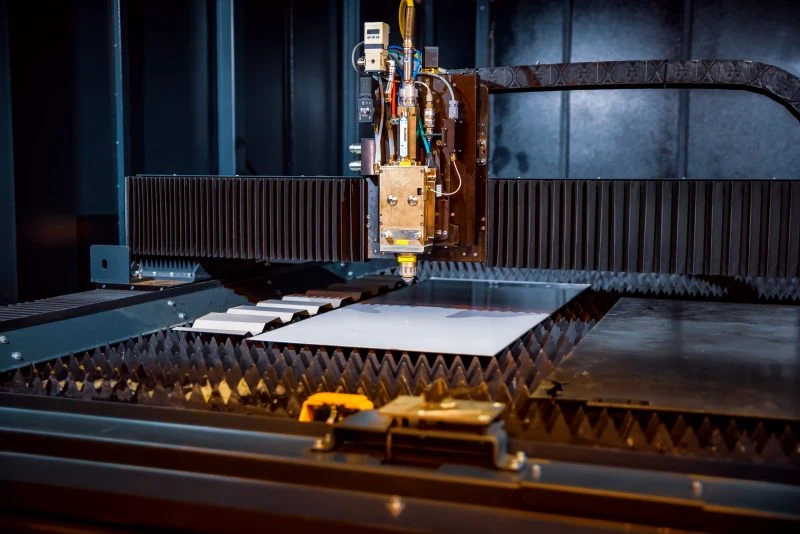

A Computer Numeric Control laser cutter, or CNC laser cutting machine, uses optics, an air assist gas, and software-generated guidance to direct and focus a laser beam into the workpiece or working area. Although laser cutting has been used in the manufacturing industry since the early 1970s, CNC laser cutting has raised the bar because it can create precise shapes in virtually any material dictated by a computer or software controller.

Different types of CNC laser cutting machines are designed to handle varying materials, projects, and volumes. At Steelway Laser Cutting, we use first-class machines from the TruLaser series 1000 that do more than cut a wide variety of materials. However, it can also cut individual and distinctive shapes. Our TruLaser 1030 fiber CNC Cutting Machine also optimizes the manufacturing process to make every project (sometimes with volume orders of 1,000 units per project or more) reliable, high-quality, and cost-efficient.

How Does a CNC Cutting Machine Work?

Some multiple tools and steps that go into the details of CNC cutting. An established laser cutting company like Steelway Laser Cutting can provide a free consultation and overview of how the CNC laser cutting process works.

But as a general outline, from a 3D-printer style design to the eventual shipping of materials, the process for many types of CNC cutting machines.

The CNC Machine Design Process

The CNC cutting process begins with a design, regardless of whether a manufacturer uses a CNC milling or routing machine or a CNC laser cutting machine.

An engineer or designer will make a material design using a company’s precise specifications for cuts or engraving. However, the software creates a 3D printer-type design instead of using a traditional blueprint.

These technological tools include CorelDRAW software, AutoCAD software, GRBL firmware, and other design support tools that create detailed instructions for the CNC cutting machine. (Hobbyists and computer engineers may recognize some of these design software tools, as they can feed details to a 3D printer or other machines, such as engraving machines.) By the end of the 3D printer-style design process, the manufacturer will have a computerized drawing. Furthermore, it can be translated by a CNC programmer into a workpiece or part with the assistance of computer-aided manufacturing (CAM) software.

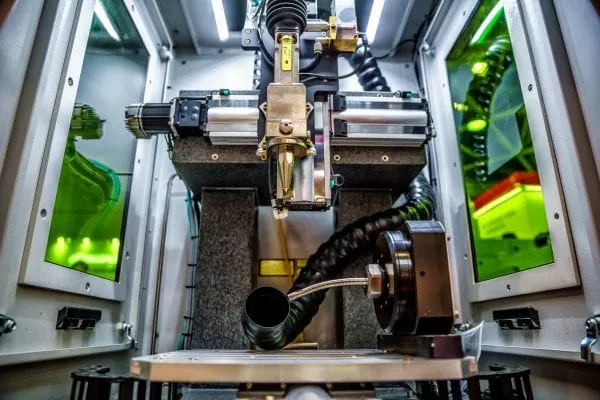

The next step is connecting the CAM software to the original 3D-printer style design. The CAM software allows a programmer to create a detailed toolpath and effectively generate the G-code, which controls the CNC machine. As such, the CNC machine can interpret these specifications, engraving or cutting everything from flat sheet materials to cylindrical objects.

The CNC Machine Cutting Process

Once the computerized design and specifications have been fed to the CNC cutting machine, it’s time to start cutting, engraving, and manipulating the materials, whether wood, metal, or another substance.

Non-laser CNC machines can be broken down into two categories under a larger, blanket definition: CNC milling machines and CNC routers, which use X-axis, Y-axis, and Z-axis parameters to get the job done.

In the cases of CNC milling machines and CNC routers, the cutting tool moves side-to-side along an X- axis, in and out along the Y -axis, and up and down on a Z axis. The X-axis, Y-axis, and X-axis are important components of the process. A CNC mill machine and a CNC router can handle multiple axes simultaneously, resulting in fast but fairly precise cuts or engravings.

Both of these CNC machines use cutting tools that remove material in order to create the desired shapes. Additionally, they can drill, engrave, and cut multiple workpieces, including steel, aluminum, and wood, to create parts or products.

Understanding the Difference Between CNC Routers and CNC Mills

The CNC router is a fairly universal and easy-to-use tool in modern machine shops. The primary purpose is to cut more delicate or softer materials, such as wood, plastic, acrylic, or foam. The CNC router tends to be mounted on a stationary workspace, with a spindle that moves along the X-axis, Y-axis, and Z-axis.

The CNC mill performs the same operations but mainly moves in an X -axis and Y- axis configuration, with the spindle moving on a linear axis above the workpiece. This allows CNC mills to tackle thicker materials, like strong and tough metals.

The CNC Laser Cutting Machine Process

An important distinction when it comes to CNC laser machine cutting versus CNC milling and routing machines is the process. All CNC machine methods follow the software instructions that are programmed in advance. However, the CNC laser machine cutting process is distinctive and much more specialized.

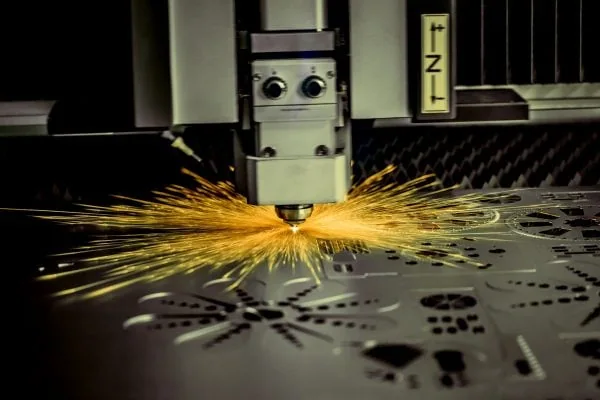

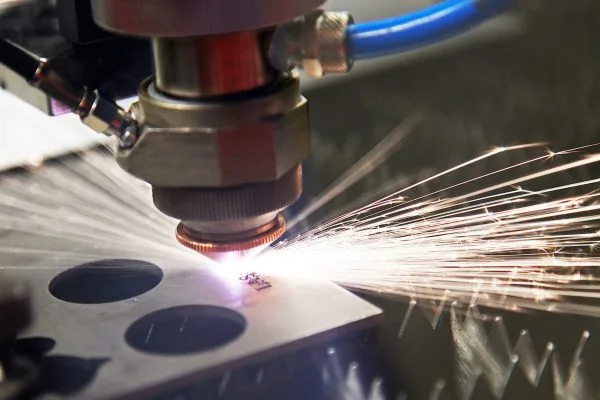

Instead of using a cutting tool or a router bit, the CNC laser cutting machine relies on a high-energy laser beam or laser module that burns through the material, creating the shape of the workpiece.

Laser cutting machines are always evolving, but three primary types of CNC laser cutters exist.

- The CO2 laser cutting machine runs electricity through a tube filled with a mix of carbon dioxide, hydrogen, nitrogen, and helium. While a top-quality CO2 laser cutting machine can cut thin metal sheets and similar materials, it is typically used for wood products and engraving.

- A fiber laser cutting machine amplifies its laser beam using special glass fibers. Known as adaptable laser cutting machines, fiber laser cutting machines can work with a wide array of materials, including metals and non-metals such as wood, plastic, and even glass.

- The Nd: YAG laser cutting machine allows for high -power laser cutting using nd:Yag crystals. These laser cutting machines are not popular in manufacturing simply because they have a high cost, and a short life expectancy. This means that additional money is needed for long-term use.

The Final CNC Machine Product

If a company has partnered with an experienced CNC machine cutting partner, shipping is involved to send the parts back to the manufacturer once the project is complete. There may be an additional cost for shipping. However, outsourcing CNC machine cutting is often the most cost-effective way for manufacturing companies to construct large volumes of highly specialized parts without spending excess money.

Bear in mind that the laser module is often more effective than anything created within an in-house cutting system simply because of the precision ingrained in every part.

The Benefits of Using a CNC Laser Cutting Machine

Precision is one of the primary advantages of using a CNC laser cutting machine. Overall, the smallest radius that a manufacturer can expect with a CNC machine is around 062″ using a 1/8″ diameter end mill. But a laser module can accomplish a radius of about .005″, providing finer detail when it comes to cuts or engraving.

In addition, laser modules leave any edges of a cut component clean and properly sealed, improving the appearance and functionality of the end-result parts. The laser module also maximizes the number of usable parts in any given workpiece or work area and produces less waste along the way, reducing costs.

CNC laser cutting machines also have a high life expectancy simply because the laser module does not require constant repairs or replacements to keep working. This means that manufacturers who outsource their projects to a laser cutting machine specialist can expect to save time and money. Also, once the laser engraving or laser cutting process is in place and rolling, work can continue 24/7 until all perfectly designed components or parts have been completed.

What is Laser Engraving?

Keep in mind that while the above processes and benefits outline the laser cutting process, laser engravers are also available. When it comes to laser engraving, the laser engraver process works very similarly to the CNC laser cutter process.

Laser engraving is an effective operation that uses the laser module to vaporize materials into fumes, allowing the laser engraver to create permanent, deep marks. Like laser cutting, a laser engraver removes material from a workpiece to create a finished product, and the laser engraver effectively works as a chisel, sculpting a new part out of existing material.

Experienced CNC laser cutting companies like Steelway Laser Cutting can provide more details on laser engravers (and the laser engraving process). This is ideal for manufacturers who need more engraving-style work than simply cutting parts for their product production. Bear in mind that while it’s possible to purchase laser engravers to use in-house, outsourcing the laser engraver work is often a better option. Moreover, allowing an expert to handle the laser engraving can save time and money, with shipping included in the total budget.

What Type of Companies Should Use a Laser Cutter for Their Production Needs?

When it comes to a CNC cutting system, some industries will benefit from a CNC laser cutter versus a CNC router or mill. All CNC cutting processes use a computer controller or control box to adjust the shape and form of a working area. However, the precision and stress-free process offered by CNC laser cutting machines work well with industries that need all parts to be perfect.

Electronic manufacturers, automotive manufactures, tool manufacturers, medical supply companies, and fabricators are all examples of companies that benefit from the support of laser cutting services within a budget. Pick a company you know has decades of experience and can provide a free consultation and use that as a launching point to determine if CNC laser cutting is the right process for your needs.

Partner with Steelway Laser Cutting for the Best Laser Cutting System and Support

There are many factors to consider when identifying the right process for cutting and shaping the materials you need for your manufacturing company’s many components. There are different motors that may power a cutting machine. Therefore, the upkeep required to keep these motors and other parts running smoothly for the long haul can be achieved by outsourcing your laser cutting needs. Outsourcing may be the best budget pick or decision to save your company money well into the future.

When deciding on a partner for CNC cutting, the key is to find an established company that can offer ample free support and guidance along the way. A solid and reliable cutting system requires ample room to adjust designs based on precise specifications and an ensuing cutting process that leaves nothing to chance.

CNC Cutting Support and Services Offered by Steelway Laser Cutting

At Steelway Laser Cutting, we have worked with manufacturers and small and large companies across all industries to launch timely, cost-effective projects and save our partners’ money.

As a second-generation family business in the manufacturing industry since 1963, we understand how essential it is to produce products in a timely and cost-saving manner, with no room for errors, missteps, or delays along the way.

This is why we use the most advanced CNC laser cutting machine technology. Also, we enlist two certified laser operators to oversee these projects in a specialized facility with state-of-the-art tools.

With Steelway Laser Cutting at your side, you can rest assured that you are accessing the most innovative technology possible to laser cut, bend, and weld to your specific requirements.

All of our projects are performed collaboratively and one-on-one with our clients, and we are happy to provide a free production plan for your project. Furthermore, we can provide more information about the intricacies of CNC laser cutting machines.

Let’s find a better way to ensure your manufacturing company has the support and resources it needs to ensure smooth operations for years to come.