When it comes to sheet metal fabrication, laser cutting is revolutionizing the way that companies across all industries are conducting business. Featuring the highest levels of speed and precision, sheet metal can be effortlessly cut and shaped through the laser cutting process. The laser cutting process can help save time and costs along the way.

Laser cutting has been around for over 60 years, and companies like Steelway Laser Cutting have been involved in the manufacturing industry since 1963. Recently, it has gained popularity across various sectors, from electronics companies and medical device manufacturers. Both industries need precise cuts to artisans aiming to produce detailed designs. Sheet metal laser cutting can significantly boost the productivity of businesses of any size.

The best way to discover if sheet metal laser cutting can enhance your unique business is to start a conversation with an expert. Business owners can certainly Google “sheet metal cutting near me” and be flooded with results. However, it takes a consultation with a professional team to understand the details of how sheet metal laser cutting can provide streamlined yet outsourced services and exceptional results.

Regardless of how a laser cutting service provider can enhance your business, there are some broad-stroke ways sheet metal laser cutting is revolutionizing the manufacturing industry, one project at a time.

What is Sheet Metal Laser Cutting?

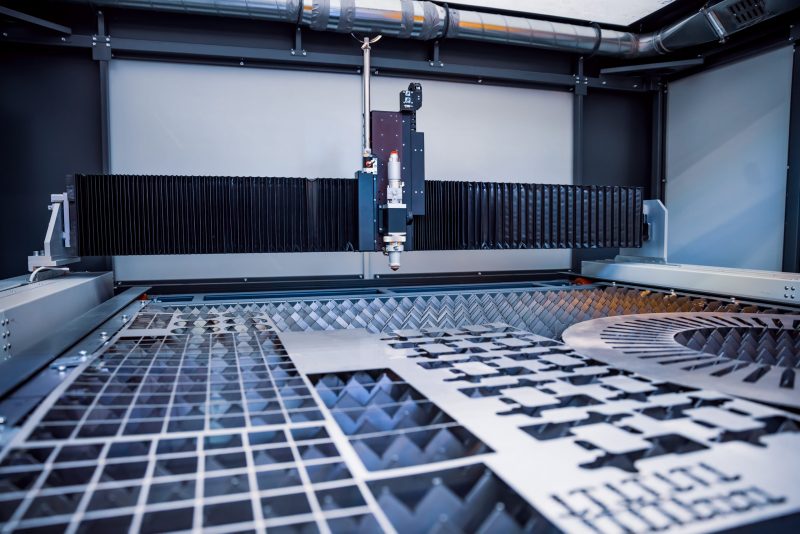

Sheet metal laser cutting is a cutting process that relies on the heat of a laser beam to vaporize materials on a workpiece in order to create a desired cut or shape. The process begins with a set of guidelines created with computer-aided design software, which are then fed to the laser cutting machine. From there, the laser cutter internalizes the instructions for each part or product and repeats the process using computer numerical control (CNC) until the required number of units is complete. The operation can run from start to finish without interruption and without alterations from one end-result part to the next.

The process sounds simple (and it is), but it requires a few additional factors to be effective. For one thing, having a state-of-the-art facility that is a perfectly clean environment will ensure the best results. On the other hand, because the technology involved in laser cutting is so specialized and technical, certified laser operators are required in order to oversee the operations. In addition, the best laser cutting machines create the best levels of efficiency. Therefore, it’s imperative to have the most modern and top-of-the-line laser cutting machines at your disposal.

Because of these factors, manufacturers of all sizes and across all sectors often find that it’s more cost-effective to outsource their laser cutting needs instead of purchasing the equipment, hiring the technicians, and building the facilities required in house.

What Are the Key Benefits of Sheet Metal Laser Cutting in the Manufacturing Industry?

When it comes to the benefits of laser cutting for sheet metal fabrication projects, the list is lengthy. A sample of the advantages of laser cutting services is listed below.

Enhanced precision

Laser cutting provides the most intricate cuts available since the cutting process is so precise and is aided by the most modern technological tools available.

The best laser cutters can achieve even the tiniest cuts or engravings, which are replicated seamlessly for every unit, resulting in perfect results time after time. This is why laser cutting has been embraced by industries that require absolute precision for their products to work. For instance, the automobile industry, the electronics industry, and the medical device industry. An inaccurate cut can damage an entire product, but laser cutting eliminates this risk more than any other cutting method available.

Better versatility

Another benefit of laser cutting is the sheer range of sheet metal and other materials the process can handle. Laser cutting can tackle the toughest types of metals, like copper, brass, thick sheets of stainless steel, and other materials like wood, plastic, or glass. As such, manufacturers that require various base materials for an overall product do not have to switch cutting methods along the way. Additionally, they can tackle all projects effectively, saving both time and overall costs.

Reduces costs

There are a wide range of ways that the laser cutting process reduces overall costs for companies in virtually any manufacturing industry. Since laser cutting is so precise, it can maximize the use of every individual piece of sheet metal, reducing waste and the cost of overall materials.

For another, because the process is automated with no human involvement, the process can run quickly and efficiently without extra labor. Finally, because laser cutting offers an unparalleled level of quality control, there are no lost costs due to ill-made or ineffective parts or products. Simply put, when it comes to saving time and money, the laser cutting process has no equal.

How to Find Out More About Sheet Metal Laser Cutting

As stated, laser cutting can be expensive to explore in-house, especially if your business is transitioning from traditional cutting methods to laser cutting services for the first time.

But the good news is that outsourcing your laser cutting manufacturing needs still provides the cost and time-saving benefits naturally inherent to sheet metal laser cutting.

The first step is to start with an expert consultation. At Steelway, we’ve helped clients across all industries streamline their operations with timely and professional laser cutting services, and every project begins with a one-on-one conversation so we can fully understand your business, your budget, and your goals when it comes to future growth and enhanced productivity.

Many of our clients are surprised to learn how fast, efficient, and cost-effective outsourced sheet metal fabrication services can be, and we’re standing by to help you revolutionize how you do business.

Laser cutting is the best tool for manufacturers that want to provide the best products, and Steelway can help. Reach out to us today to start the conversation. Let’s work together to integrate laser cutting into your operations to create a more successful business across the board.