Metal laser engraving is a technique that large manufacturing companies and everyday hobbyists use. Metal laser engraving can fulfill a wide array of needs from crafting personalized jewelry to creating permanent markings in parts and products for large corporations.

However, there is a lot to know about a business that requires the best laser engraving machines in the industry to fulfill large orders or a modestly priced laser engraving machine to engrave metal on a small scale. The laser cutting, laser etching, or laser engraving process works in specific ways. From the exact laser cutter or laser source to the varying metal surfaces or even non-metal materials that work best with a specified laser engraver. Here’s what you need to know about laser engraving, laser marking, laser cutting, and everything in between.

The Different Ways Laser Systems are Revolutionizing Technology

What is the Process of Laser Engraving?

Which Metals and Materials Work Best with Laser Engraving?

Different Types of Laser Machines

Receive Precise Metal Engraving with our Laser Cutting Services

The Basics of Laser Engraving

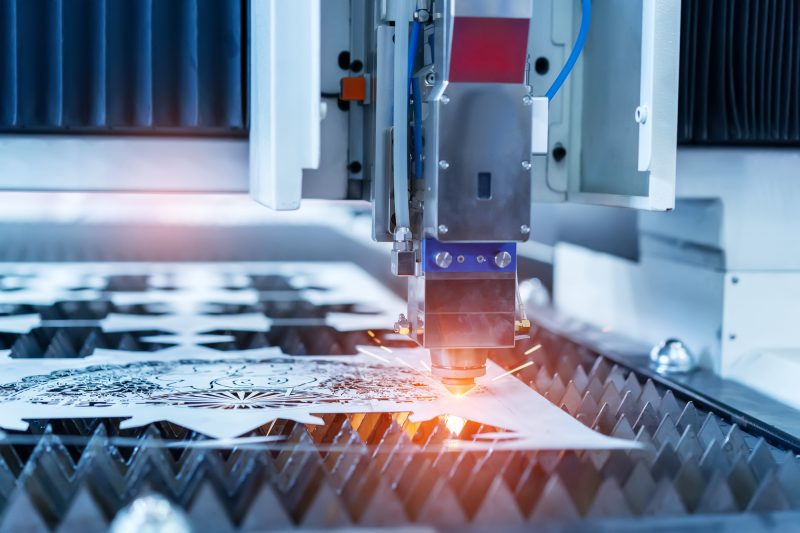

Laser engraving is a process that uses a high-powered laser beam to create permanent marks on a metal surface or other non-metallic materials. The process of a laser system is ultimately more effective than engraving, marking, or cutting techniques. Furthermore, the infrared laser beam targets the metal’s surface with the utmost degree of accuracy in the engraving area. Then, it melts away the material and leaves behind the metal marking. The eventual engraved surface then has a permanent mark or design based on the exact specification, which meets all laser engraved specifications and will stand the test of time.

Bear in mind that there are a few terms that are commonly thrown around when it comes to laser engraving, like laser etching, laser or metal marking, and laser metal cutting. While the best laser engravers can tackle most of these processes simultaneously via the same laser system, it’s essential to understand the differences between each engraving process and have the right laser engraver for the job at hand.

The Different Ways Laser Systems are Revolutionizing Technology

Laser Cutting

Laser cutting entails using a top-notch laser cutter (like a fiber laser) to remove excess material from a metal surface to create a specified shape for a part or product. Additionally, laser cutting metals are common across manufacturing sectors like automotive, construction, aerospace, and electronics. Using laser power to cut metals and construct parts or products is the most productive and time-saving way to complete large manufacturing projects efficiently and at an impressively fast speed.

Laser Engraving

Laser engraving removes the top layer of materials, like metal and plastic surfaces, to create a design in the surface material without causing a complete cut. (Top laser machines like a fiber laser are commonly used for large laser engraving projects and finely tuned laser markings and details.) The laser engraving process typically results in deep engraving. Manufacturers or other companies can use it on a larger scale to create logos, barcodes, stamps, and other metal markings.

Laser Etching

Like laser engraving, laser etching uses the focused heat of a laser beam to create a laser marking on a surface. However, laser etching is a much more delicate process, and the ensuing metal laser marking is not as deep or defined as in the laser metal engraving process. The laser etching of metal or other materials results in small and often decorative details. The process is common in craft projects, jewelry design, or the perfection of precious metals. Simply put, a surface material that is laser engraved will have deep engraving, while laser etching will leave a more delicate metal marking. However, both processes can often use the same laser source or laser engraving machine to complete the task.

What is the Process of Laser Engraving?

Regardless of the specific laser engraving machine you utilize for a project, the laser engraving process generally follows a similar series of steps. This all depends on the metal engraving or other engraving projects. A trusted resource for laser cutting and laser engraving, is a powerful partner for orchestrating the laser engraving process. It will often have the best laser engravers on hand to ensure that your small or large laser engraving projects are completed perfectly, time after time.

So, regardless of whether you are using a diode laser, fiber laser, or other laser machine for laser engraving metal, the process is typically as follows.

First, an intricate design is fed to the laser engraver, generally created by computer aided design (CAD) software. The design has all the specs for the laser spot to target and serves as the guideline for metal laser marking to the smallest detail.

Once the laser engraving machine has the specifications and the laser marking that needs to be conducted, the laser engraving process then entails the sublimation principles. This is where the solids are rapidly transformed into a gas without passing through the intermediate liquid state. With the laser head focused on the material, the surface temperature reaches a point where the particles vaporize, revealing the laser engraved design. The ensuing engraved metal surface can be easily treated with a protective coating or remain as a complete metal product as needed.

Which Metals and Materials Work Best with Laser Engraving?

With some limitations, a top laser machine (like a fiber laser machine) can traditionally engrave metal, plastic, wood, and everything in between. With that being said, there are specified laser engravers for metal projects, and other types of projects, and a little research is required to determine the best laser engravers for metal or other surfaces.

Overall, a metal laser engraver explicitly designed for metal laser marking can handle a wide array of metal materials. This can include anodized aluminum, stainless steel, carbon steel, and various other materials that require a light touch for the laser engraving process, including plastic surfaces.

Stainless steel is arguably the most popular and most used material for engraving metals, particularly in the manufacturing industry. In these large-scale metal projects, the metal laser engraver creates essential indentations and designs, such as barcodes, logos, or even instructions, for example stainless steel appliances or stainless steel automotive parts.

Whether you use laser engravers for stainless steel or other metals, it’s essential to have the right laser machine and the right laser engraving resources to complete a project. Metal laser engravers are not created equal. Therefore, it’s essential to partner with a resource that has the best laser machines available if you want the best results.

Different Types of Laser Machines

A wide array of laser machines can assist in the metal engraving process. Additionally, the laser engraver an individual or company will highly depend on their desired results.

A cost-effective laser engraver is a good fit for craftspeople, artists, hobbyists, startups, and companies that do not utilize metal engraving on a regular basis. However, bigger and better laser machines, (like fiber lasers) are required for companies and businesses that need to engrave metals at the highest levels of precision and efficiency, time after time.

Simply put, the options are numerous, and depending on the laser engraver, the laser machine may require additional parts, like a rotary attachment, to be most effective.

With that being said, here are a few of the most commonly used laser machines or laser engravers for metal and other materials.

Fiber Lasers

A fiber laser is an ideal tool to laser engrave metal and other materials, as a fiber laser can create the most intricate and detailed laser engraving without impacting the integrity of the surface material. Fiber lasers can be expensive and may need expertise to operate. However, a fiber laser is ideal for large manufacturing projects or any metal project that requires a high degree of precision. While a fiber laser works well for metal marking on stronger materials, like stainless steel, it may not be the best fit for very delicate materials, like thin plastic surfaces or glass.

CO2 Lasers

CO2 lasers are highly efficient laser machines. They can also function as laser engravers when necessary. Generally used on a larger scale, particularly to engrave metal in manufacturing, a CO2 laser machine can handle a wide array of metal marking projects on all varieties of metal services. The laser module and laser head in a CO2 machine are very precise. However, CO2 machines can be costly for smaller projects, and a laser master or technician may be needed in order to handle the specifics. When it comes to metal laser engraving or cutting, CO2 laser cutting machines often require a high degree of skill to operate. So, background knowledge and expertise in laser systems are instrumental for success.

Diode Lasers

A diode laser is an efficient and cost-effective laser engraver that can handle smaller projects on a routine basis. Diode lasers are commonly used by artists and small businesses simply because a diode laser can be purchased in-house and can be used to laser engrave metal with acceptable results. The main issue with a diode laser is that it does not have the efficiency, speed, and precision of other, better quality laser engravers. As such, a diode laser is a good fit for metal laser engraving projects that are smaller and do not necessarily have to be 100% perfect every time (like in artistic projects or endeavors.)

Ortur Laser Master 3 and Ortur Laser Engraver

The Ortur Laser Master 3 and Ortur Laser Engraver are two specific laser engravers on the cost-effective side of the laser engraving spectrum, costing around $1,000 or less. The Ortur Laser Master 3 has a tight laser spot size, leading to better accuracy for metal laser engraving. Meanwhile, the Ortur Laser Engraver is slightly less expensive at around $400 and is a lightweight but slower option for laser engraving projects. The Ortur Laser Engraver and Ortur Laser Master 3 can be used for varying craft or metal laser projects (and the Ortur laser master is particularly effective for more intricate designs). However, they should not be used for large undertakings or by companies that want the best speed and precision for multiple laser engraving projects.

xTool D1 Laser Engraver

The xTool D1 Laser Engraver is an entry-level diode laser that can create high resolution laser engravings and is generally a cost-effective option for smaller projects. The xTool D1 is a good option for laser engraving metals on a small scale. However, like the Ortur Laser Master 3 and Ortur Laser Engraver (and other diode lasers), it’s not the best laser engraver for larger or highly detailed projects.

Other Laser Engravers

Search for the best laser engraver for metal or metal laser machines for engraving, and you’ll be flooded with options. Some of these laser machines are cost-effective and easy to use, with a laser module that requires limited skills. However, an inexpensive laser engraver for metal or other materials may not be able to tackle every project to your exact specifications. Some accessories may need to be purchased, like a rotary attachment. Therefore, the laser beam may not be precise enough to repeat the same laser engraving process perfectly and exactly, time after time.

This is why, when it comes to metal laser engraving or laser cutting, your best bet is to partner with an expert resource with the best laser machines and laser engravers on the market. Laser engraving in metal projects comes in all forms and styles and requires different tools for laser engraving metals and other materials. As such, when it comes to metal laser cutting, laser engraving, and laser etching, you need an expert who can point you in the right direction – regardless of whether you conduct your laser engraving projects in house or through a trusted outside resource.

Steelway Laser Cutting – Top Experts Ready to Assist You with Your Project

In order to laser engrave metal, plastic, wood, or other materials, you need the right tools, skill set, and resources. A laser engraving project can be difficult to navigate, especially for manufacturers in larger industries (like the automotive industry), where large-scale production and perfect results are continually required.

Small-scale businesses, entrepreneurs, artists, and individuals can always utilize an inexpensive option to laser engrave on a smaller scale. There are plenty of machines that are specifically designed to laser engrave a unique artwork or decorative piece at home, which is a great option for conducting metal projects on a limited and inexpensive basis.

But if your business relies on perfect laser cutting and laser engraving results every time, then you need a better way.

Receive Precise Metal Engraving with our Laser Cutting Services

At Steelway, we handle laser cutting, laser engraving, and all types of metal manipulation projects in a timely manner. We can also handle large orders that require perfect execution for every part or product.

Let’s discuss more about your company, your ambitions, and your pain points when it comes to your manufacturing processes. With the experts at Steelway guiding the way and serving as the backbone for your laser engraving needs, you can rest assured that your operations run as smoothly as possible, with perfect laser engraving results that will exceed expectations.

When it comes to laser engraving metal or any materials, Steelway Laser Cutting services is your best resource to get the job done efficiently, quickly, and as successfully as possible.