Manufacturers and businesses across all sectors are trying to identify new ways to be more environmentally friendly. This shift to greener processes is due to a wide range of reasons. These reasons include everything from conforming to new state or federal regulations to simply trying to leave less of a footprint for future generations.

However, transforming manufacturing operations to be more environmentally friendly is not always easy. Manufacturing across all sectors, from automobiles to new home construction, inherently demands significant amounts of raw materials and labor. Therefore, identifying eco-friendly practices that not only save money but also contribute to sustainability may not be immediately evident.

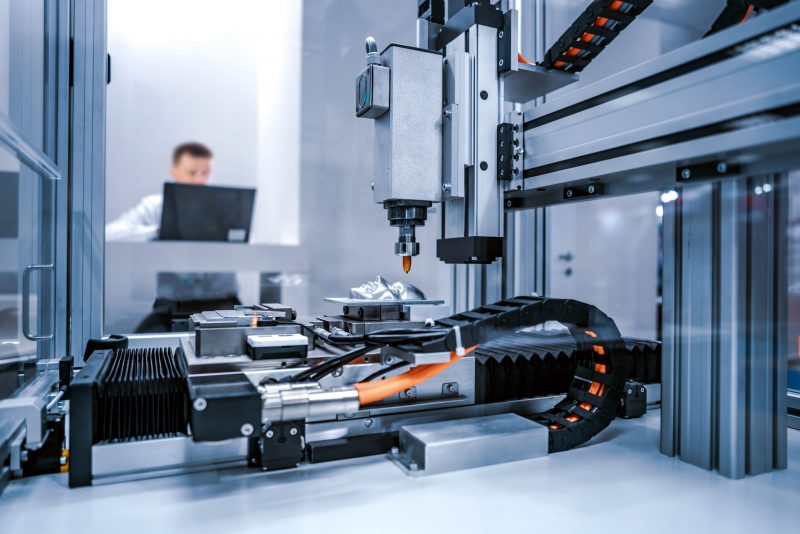

However, this is where CNC laser cutting makes the difference. A modern laser cutting machine (like a CO2 laser cutting machine) saves time, money, and errors and is better for the environment in a myriad of ways. From laser cutting materials used in the everyday production of products to engraving and bending parts to precise specifications, here are the top reasons why laser cutting is a solid alternative to traditional cutting options for manufacturing businesses.

Understanding the Laser Cutting Process

Laser cutting is the process of cutting, bending, laser engraving, or shaping raw materials like sheet metal to precise specifications in order to form a complete product or part. Laser cutting isn’t necessarily new – the first laser cutting machines were introduced in the 1960s and 1970s in the aerospace industry. However, modern tools and techniques have evolved astronomically over the past few decades.

In today’s laser cutting process, Computer Aided Design / Computer Aided Manufacture software (or CAD/CAM) is utilized to spell out the detailed instructions for each piece of sheet metal or other material that needs to be cut. Once these details are fed to a CO2 laser cutter, fiber laser cutter, or other high-tech laser cutter, the machine does the rest. The process is repeated as many times as necessary until all units are complete, with no delays due to human involvement, repairs or maintenance, or other interruptions that can slow down a more traditional cutting process.

The Environmental Benefits of Laser Cutting

The inherent nature of the laser cutting process means that there is a realm of environmental benefits that are simply part of using laser cutters for manufacturing purposes.

Let’s explore the following elements of the environmental benefits of laser cutting.

Reduces Energy Consumption

Modern laser cutting machines inherently use less power than traditional types of cutting machines. This leads to less energy consumption throughout the cutting process. For example, a fiber marking laser has been shown to use 70% less power than typical machines that conduct a similar process. The trick is to partner with a laser cutting services provider that uses the most modern machines in the industry to reduce time and energy on every specified manufacturing or cutting project.

Reduces Waste in the Manufacturing Process

Laser cutting machines operate differently than older styles of cutting machines. Instead of cutting bits of material from a larger piece of sheet metal or other material, the laser simply uses heat to remove excess material, resulting in the desired shape. As a result, this leads to less scrap or excess material, which is not only good for the environment but also for manufacturers who want to cut down costs on raw materials across the board.

Reduces Excess Materials and Processes for Manufacturing Products

Depending on the industry, manufacturers often have to use extra materials and processes to affix necessary additions to a part or product. Some examples include adding barcode or serial stickers, logos, and/or safety information. However, modern laser cutters and laser engravers can eliminate this part of the manufacturing process entirely by using detailed engraving to add these tiny but essential details. As a result, manufacturers will use fewer materials, saving both money and resources like paper, stickers, ink, etc.

Reduces Production Time

One of the simplest ways for a manufacturer to reduce energy consumption is to simply reduce production time, and laser cutting machines are renowned for their exceptional speed. Once a laser cutting machine is fed the specific directions for a project via CAD software, the machine does the rest and can work 24/7 without interruptions.

Laser cutting machines require little maintenance and no human involvement or interaction to finish a project of 1,000 units or more, so the entire process can run seamlessly until complete. This method allows manufacturers to avoid shift work and interruptions for repairs or adjustments. As a result, projects can be completed swiftly and efficiently, reducing operational and energy expenses.

Laser Cutting Machines are Sustainable

As stated, a laser cutting machine requires very little maintenance compared to older cutting machines, as no replacement parts, upgrades, or maintenance is required. This saves money on upkeep for existing machines, but it’s also better for the environment. Laser cutters can handle all types of projects – and materials – without costly replacements.

Partnering with a Laser Cutting Services Provider for a Greener Approach to Business Operations

Using laser cutting machines to conduct your manufacturing processes is not just a time and cost-saving strategy –also has deep-rooted environmental benefits. By utilizing laser cutting technology, your company can reduce its daily consumption of raw materials and save money and energy in the production of each part or product. This modern and innovative approach to manufacturing allows you to operate more eco-friendly while increasing your profits.

The key to launching a successful laser cutting project is to start with a trusted and experienced partner, and that’s where Steelway Laser Cutting can step in and take the reins. At Steelway Laser Cutting, we have assisted businesses across all industries to find a cleaner, faster, and better way to tackle their manufacturing projects. Additionally, we are ready to help you find a new way to increase efficiency across the board.

Reach out to us today to tell us about your cutting, welding, and other needs. Let’s work together to naturally add a more environmentally friendly way to improve your manufacturing operations from the inside out.