Let’s discover everything you need to know about laser cutting for precision parts production. Using lasers to custom cut metals of all varieties is not a new process. Laser cutting was in the 1960s and utilized in the aerospace industry before laser cutting became commercially available in the 1980s. Additionally, metal laser cutting services have grown in the past few decades.

In our modern era, laser cutting metal fabrication has reached new heights. It also can create thousands of custom and intricate parts that are perfectly cut every time. Additionally, modern laser cutters are the preferred vehicle for manufacturing in numerous industries.

So how has technology revolutionized the laser cutting process? How can you find an experienced partner and laser cutting services provider beyond a simple search for “metal laser cutting near me?”

Understanding the new technology begins with a basic review of the laser cutting process, from start to finish.

Laser Cutting Technology in Precision Manufacturing

On the surface, the laser cutting process is deceptively simple.

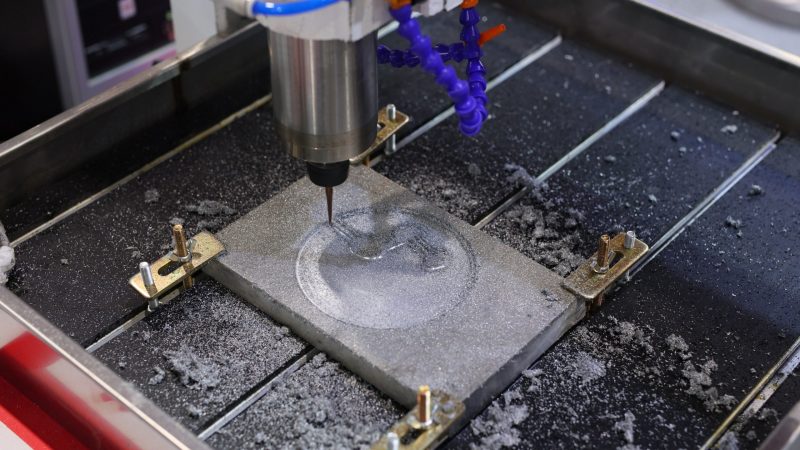

Specifications for the cuts, bends, and other adjustments required for any piece of metal or other material are outlined in a software-generated design. These schematics and instructions are then fed to a laser cutting machine. Then, it automatically follows the directions to the letter. Instead of punching or cutting, a high powered-laser beam vaporizes the metal or material to create these intricate cuts, allowing for incredible accuracy.

Unlike basic cutting machines, which can be subject to human error, the laser cutting process is amazingly precise. It can be repeated as many times as needed to complete a project.

Why is Laser Cutting so Accurate?

There is a wide range of reasons why modern laser cutters are considered the best option for accuracy. These reasons include the following:

- Automated process: Because a laser machine uses a computer aided design, there is no human involvement. Therefore, precise cuts can be identical in every part, and manufacturing projects can be completed at a fast rate of speed.

- Less material damage: Unlike other cutting methods, laser cutting results in less damage to the base material simply because there is no direct contact or cuts. Instead, the laser uses heat to create the cut parts, and less material damage means more consistent results.

- Fiber optic precision: Modern laser cutters use fiber optic lenses to guide and control the laser beam, which helps to ensure a direct point of precision.

- Less maintenance: Unlike traditional cutting methods, laser cutters require little maintenance. This means they can be used consistently, and for multiple projects without mechanical issues along the way.

What is a CNC laser Cutting Machine? How Does it Work?

When industry professionals talk about modern laser cutting machines, they generally refer to CNC Laser Cutting machines. They are on the cutting edge of manufacturing technology.

A Computer Numeric Control laser cutter, or CNC laser cutting machine, uses optics, an air assist gas, and software-generated guidance to direct and focus the laser beam into a material.

At Steelway Laser Cutting, we use a TruLaser 1030 fiber CNC Cutting Machine and other tools from the TruLaser 1000 series that cut a wide array of distinctive shapes. However, it also has multiple functions enabling bends, welding, and other manufacturing processes.

As a general outline, in modern laser cutting machines, a 3D-printer- style design is created instead of a straightforward blueprint. It can then feed into the machine to provide detailed instructions.

Once this computerized design has been finalized and shared with the laser cutter, the laser is directed to the material and repeats the process as many times as necessary.

When it comes to modern laser cutters, there are generally two distinctive types:

- The CO2 laser cutting machine functions by running electricity through a tube that is filled with a mixture of carbon dioxide, hydrogen, nitrogen, and helium. This laser cutting machine is ideal for thin metal sheets. Also, there are similar materials and that can also be used for wood, glass, and other materials outside the metal realm.

- A fiber laser cutting machine uses special glass fibers to amplify the laser beam and create precise cuts every time. Fiber laser cutting machines are especially versatile and can cut several materials, including sheet metal, stainless steel, wood, plastic, glass, and even thicker materials like copper and bronze.

Keep in mind that there are other types of laser cutting machines on the market. However, CO2 and fiber cutting machines are two of the most utilized by companies across all sectors.

What is Precision Laser Cutting Capabilities?

The exact specifications of the cuts will depend on the material and the laser cutting machine itself.

As an example, our TruLaser 1030, which runs on CNC programming and nesting software, can handle a wide array of materials with max sheet metal sizes of 120” x 60” as a starting point. Click here to see our individual material capabilities, and know that this is just a sample of the types of projects we can orchestrate.

Start Utilizing Innovative Technology for Manufacturing with Steelway Laser Cutting Services

Ensuring the most accurate projects possible starts by partnering with the best laser cutting services provider.

Our expert team has decades of experience, and our facilities, machines, and expertise have grown with the onset of new advancements in laser cutting technology.

As a result, we can handle projects of all volumes and specifications with complete accuracy every time. Our on-site team of experts includes two certified laser operators. Our experts are always attuned to new advancements in the laser cutting industry and how they can benefit our clients and partners.

Revolutionize Your Laser Cutting Projects with Our Experts

Ready to revolutionize your manufacturing processes? Then it’s time to reach out to our Steelway team.

Obtaining an in-house and advanced laser cutting machine is a costly process. However, most companies and businesses do not have the resources to handle these intricate projects on their own. However, with a partner like Steelway laser Cutting, you can ensure reliable cutting services for every project, regardless of the material or the volume. Also, you can enjoy a new level of productivity and precision for all your manufacturing needs.