Finding laser cutting services for your custom project is essential. There are many benefits to using a laser cutting company for your projects.

Some important benefits of laser cutting are:

- physical contact during the cutting process is limited

- non-handheld cutting methods to improve safety

- suitable for most metals

- one laser machine can cut through various types of materials

- laser cutter has better precision than other methods, such as plasma cutting

However, there are additional advantages that make it effective. Let’s discover the many benefits you can receive when you find a laser cutting company for your manufacturing projects.

What is Laser Cutting and How Does It Work?

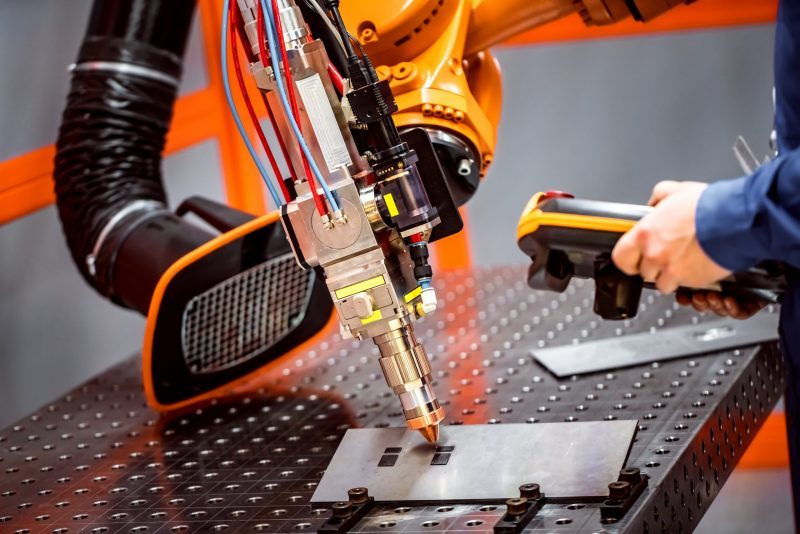

Laser cutting companies use CNC laser cutting machines to cut through various metal types using the focus and energy of a laser beam.

Laser cutting machines are extremely precise. A laser machine uses a thermal process and tight tolerances. Laser cutting companies output precise cutouts and the tiniest holes. They are often smaller than the metal’s thickness, giving you exact and extreme accuracy.

It works by feeding the machine your initial CAD file. The device then utilizes the laser to cut the metal through burning, melting, or vaporizing.

There are three standard processes. Laser cutting companies use machines that work with:

- Carbon Dioxide (CO2)

- Fiber

- Or Neodymium-doped yttrium aluminum garnet (YAG) lasers

Laser cutting machines are high-tech, but what are the main advantages in the industrial and manufacturing sectors?

The Benefits of Laser Cutting Services

The benefits of outsourcing laser cutting projects go beyond efficiency and extreme preciseness. Although those are great benefits, let’s consider what you can gain from custom laser cutting.

Custom Laser Cutting Offers Versatility

Laser cutting is a preferred method for cutting metals because it can be used in different ways. Although it does a fantastic job cutting shapes, you can also engrave, drill, and mark without additional tools or machines.

CNC laser cutters are easy to use and are highly versatile. You can also use a laser cutter for materials other than metals.

Some materials include:

- copper

- brass

- aluminum

- wood

- composites materials and metals

- plastic

- fabric

Your next project will have a range of possibilities if you decide to outsource laser cutting services.

A Laser Cutting Company Provides Accuracy

It’s common knowledge that lasers are highly precise. Therefore, a laser cutting machine is no different.

The accuracy of the laser cutter is due to its size and power. It works by melting the material with a laser, resulting in tolerances of between 0.003 inches and 0.006 inches.

Laser cutting is an ideal solution if you want accuracy and precision.

A CNC Laser Machine Can Add In-depth Details and Personalization

You can expect precise and accurate results for all your projects with the required details. After the machine cuts your shape, you can continue to engrave and cut patterns, pictures, or words to personalize your product.

There’s Less Chance of Warping with Non-contact Laser Cutting

One of the many benefits of laser cutting is how the laser uses heat.

Since the laser doesn’t come into contact with the metal, there is no risk of warping or discoloration. The quickness of the laser also helps keep the materials from warping as the heat-affected zone is small.

Since it’s contactless, there’s less wear and tear from the laser cutter. This saves manufacturers money on waste and repairs.

Laser Cutting Offers Cost-effective Solutions

Time is money, which is why laser cutting companies have capitalized on the quickness of CNC laser cutting machines. Laser cutters are fast. With one machine doing all the work, your product is created quicker than expected.

A custom design requires your choice of material, the CAD design, and the laser cutter. This streamlined process shortens the time and reduces costs. Your ROI has now increased due to the speed and cost-effective production methods.

Our CNC Laser Cutting Services in Pennsylvania Provides Immeasurable Safety

While using a laser to vaporize material with heat may initially appear hazardous, it is a safer alternative to other cutting techniques.

Even though wearing protective gear is recommended, it is not mandatory. Conversely, other cutting methods that use sharp objects to slice through materials pose a greater risk than laser cutters.

Utilizing a Laser Cutter Consumes Less Power

Laser cutting machines require a significant amount of energy to cut through materials. However, it uses less energy than other alternatives.

A turret punch uses over 30kW of energy when comparing energy consumption. A laser cutting machine only requires approximately 10 kW, even when cutting thicker materials.

Creates Less Waste & More Environmentally Friendly

Using more surface area (or nesting efficiently) of your metal sheets means you create minimal waste and pay less due primarily to using less material. In short, a laser cutting company optimizes the surface area of your sheet metals.

It makes your product more sustainable while reducing overall costs and waste.

Custom Laser Cutting Offers Your Designs Creativity and Freedom

Laser cutting gives you more creative freedom than other manufacturing processes. Your project manager can use CAD drawings to conceptualize your ideas without limitations. A laser cutting company can create your drawing and turn it into reality.

Which Industries Benefit the Most from Laser Cutting Services?

Although there are a lot of benefits to using a laser cutting company, some industries benefit more than others.

Laser cutting services directly affect your bottom line by utilizing efficiency, quickness, time management, creative freedom, and all of those mentioned above to work in your favor.

Nevertheless, the industries that benefit the most from laser cutting include (but are not limited to):

- construction

- freight and railroad

- agriculture

- contract manufacturing

- automotive

- aerospace

- military

- household appliances

However, if your company uses a lot of metal, consider using a laser cutting company.

Benefit From CNC Laser Cutting Services in Pennsylvania with Steelway Laser Cutting

Steelway Laser cutting is the go-to source for all your laser cutting needs. Our excellent customer service and fast, reliable process makes us the absolute best choice for even the most complex cutting requirements.

Our team of experts provides a hassle-free experience from start to finish to ensure that every order is handled with care and efficiency.

Additionally, here are other factors to consider:

- short programming time and energy-efficient nesting

- create minimal waste

- different methods to save you time and money

Contact us today to learn more about how we can help with your unique laser cutting project.