Metal fabrication is a process used across multiple industries to manufacture the parts and products we use every day. Metal fabrication is required for virtually all metal products in multiple sectors, from aircraft, vehicles, and appliances to tools.

However, not all processes are created equal when it comes to sheet metal fabrication (and other forms of metal fabrication). Therefore, for companies that require the utmost precision, reliability, and efficiency, laser cutting is the best method to conduct metal fabrication projects of all varieties and volumes.

Exceptional laser cutting services begin with an experienced resource. Laser cutting is a specialized process that demands the best equipment and technicians possible. As a result, outsourcing your metal fabrication projects becomes the most cost-effective, reliable means to ensure a smooth manufacturing process from start to finish.

If your business relies on perfectly cut metal parts to thrive, consider the many benefits of using laser cutting for all your metal fabrication projects.

1. High Precision and Accuracy

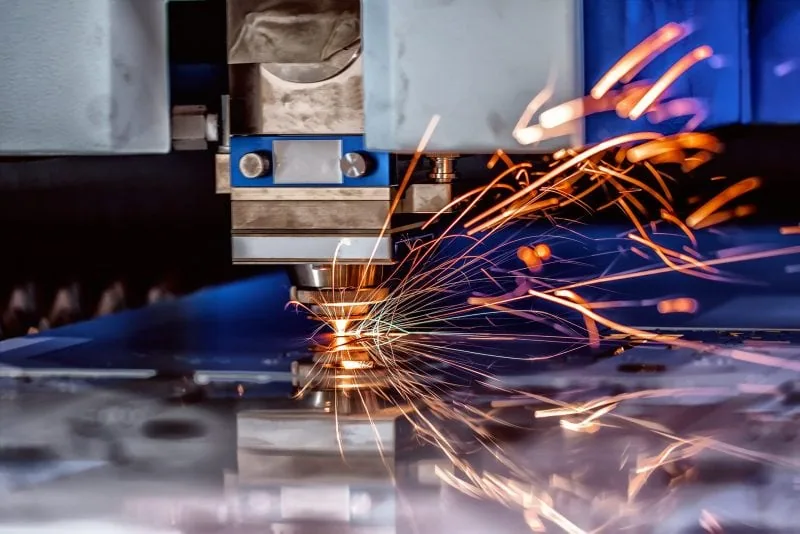

Laser cutting is different than traditional metal fabrication methods. That is because instead of making sharp cuts to an existing piece of sheet metal or other material, a highly focused laser beam melts the material away, leaving behind the desired shape. As a result, manufacturing companies will benefit from the most precise and accurate cuts possible while reducing material waste from older, straightforward cutting methods.

2. Versatility in Material Selection

One of the best aspects of using laser cutting services for metal fabrication is that virtually every metal or other material can be shaped and cut with an exceptional laser cutting machine. This includes tougher materials like copper and bronze. It also includes more delicate metals like aluminum, glass, wood, and everything in between. From stainless steel to brass, a laser cutting service provider can tackle virtually any material that a manufacturing company requires for their products with top-notch precision and details.

3. Speed and Efficiency

One of the best aspects of laser cutting for manufacturing companies that need a fast metal fabrication turnaround time to operate and grow their business is the processes’ inherent speed and efficiency. Laser cutting uses Computer Aided Design (CAD) software to create the specifications. Therefore, the laser beam does the rest once this is fed to the laser cutting machine.

Because the process is automated from start to finish, laser cutting machines can handle large volume projects at a high level of speed, with no missteps or alterations along the way. This means that every part crafted by a laser cutting machine is perfect. Laser cutting can reduce costs on mistakes. It also allows a company to complete a large manufacturing project in the fastest amount of time possible.

4. Complex Design Capabilities

Most manufacturers envision a machine that can cut sheet metals into desired shapes when they think of laser cutting. While this is certainly the most common application of laser cutting service providers, the industry’s most modern and best laser cutting machines can do a lot more. This includes processes such as welding, stamping, bending, punching, and much more. This means that even the most complex designs can be handled with ease. The CAD software helps with the creation of these intricate designs. Furthermore, all metal fabrication instances are based on this initial software, and each complex part is produced to exact specifications.

5. Automation and Customization

One of the reasons why laser cutting is so efficient, without missteps that lead to downtime in the manufacturing process, is because it’s essentially free of human intervention. The cutting process is completely automated once the design has been created with CAD software. As a result, large projects can be tackled 24/7 until the order volume is complete. Additionally, there is no need to pause to maintain equipment, change specifications, or make other adjustments once the process begins.

There is also lots of flexibility when it comes to the design parameters, simply because the laser beam is so precise and can handle manufacturing processes of all varieties. The key is to have an experienced laser cutting partner that intricately knows how to transform complex designs into precisely executed metal parts.

Learn More About Metal Fabrication with Steelway Laser Cutting

A manufacturing company can certainly purchase its own in-house equipment to conduct laser cutting projects. However, when it comes to ensuring the best results in a timely and cost-effective manner, you need a professional partner at your side.

At Steelway Laser Cutting, we utilize the best machines and technology available in order to give our manufacturing clients and partners the attention to detail and quality results they deserve. We also pride ourselves on our fast turnaround time. That means your manufacturing projects can be conducted quickly and shipped back to your organization so all operations can continue uninterrupted and run as smoothly as possible.

Start Your Metal Fabrication Project with our Laser Cutting Experts

Laser cutting is the best option for all varieties of metal fabrication projects. However, when choosing a laser cutting resource, don’t just do an online search for “custom metal cutting near me” and filter through the results. Instead, in order to enjoy the most benefits from the laser cutting process, it’s imperative to find a partner that has a lengthy record of productivity, efficiency, and quality. Our team can ensure that every single one of your projects is perfectly orchestrated, time after time.

Let’s start a conversation about how our laser cutting services can make your organization and manufacturing operations more productive across the board. We’re standing by to discuss your unique needs and requirements for custom metal fabrication and how we can put our advanced equipment, highly specialized technicians and experts to work for you.

With Steelway Laser Cutting at your side and as your resource for metal fabrication, your company can enjoy a new level of efficiency and productivity. This allows your business to thrive and grow in the future, regardless of your manufacturing needs. Reach out to our team of experts at Steelway Laser Cutting today.