When a metal fabrication project demands a precise cut that only laser cutting can accomplish, a do-it-yourself approach may be the first idea that comes to mind. Buying your own laser cutting equipment and handling the process on-site may sound like a good option. However, it’s not as easy as it seems.

What gets overlooked many times are the realities of what on-site laser cutting involves. For example, expensive investments in equipment, thorough training, and inconvenient maintenance. So, for your next job think about the time and money you can save by outsourcing your project with our company.

Steelway has provided custom fabrication services since 1963. Our first-time clients turn into lifetime clients once they see how our industrial CNC laser cutting services benefit their operations. Learn more about why many businesses choose to outsource their fabrication needs with Steelway Laser Cutting.

What is CNC Laser Cutting?

A laser seems like an easy enough concept to understand, but what is CNC laser cutting?

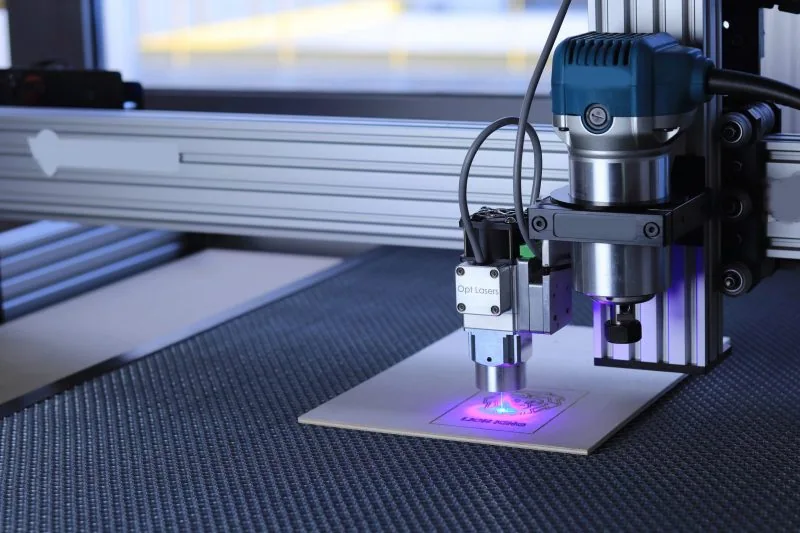

CNC stands for Computer Numeric Control. CNC is a way of combining computer software with laser technology. With CNC laser cutting, an expert creates a design based on what the customer needs using a software program like CorelDRAW or AutoCAD. Then, a piece of metal or some other material is placed on the cutting surface. The computer then sends a signal to the CNC machine, which interprets the design and outlines the shape with a laser beam. The laser moves back and forth as well as side-to-side along the axes to create the shape of the design.

5 Benefits of Outsourcing Your Laser Cutting Needs

Businesses of all sizes choose to outsource parts fabrication for one reason or another. Some can’t afford high-priced equipment. Others may not want to spend in-house time and money on volume production. Still, others don’t want to bother with material, machining, or specialized employee training needed to run their own fabrication production.

Are you debating whether or not to outsource your next project? Check out these 5 ways you can benefit from using our professional and specialized services for your laser cutting needs.

1. Speed

Time is a critical factor in any project, but the overall turnaround of laser cutting projects is very fast. When you outsource the laser cutting process, your components will be delivered pre-cut and ready to use. This allows your employees to focus on the other parts of manufacturing and production. This, in turn, will help your business improve efficiency, sell more products, and raise your business’s overall profits.

2. Capacity

Even if you can successfully manufacture a part here or there, what happens when the demand for that product increases? You will need to increase the volume of parts ordered and see that those manufacturing demands are fulfilled on time. Will you have the space, resources, and materials to get the job done consistently, efficiently, and effectively? Large companies can easily absorb the demand for mass production because they have the machinery and tools readily available.

3. Costs

Equipment

Laser cutting equipment is expensive, plain and simple. Spending money on expensive laser cutting equipment isn’t practical for most companies. Especially if your business won’t use it often. This can directly make your products more expensive and less marketable. Some larger machining companies might be able to justify the costs because they frequently use the machines. However, if you only need certain items or products to get laser cut, it’s best to outsource.

Maintenance

CNC laser cutting equipment has complicated parts that require constant maintenance. Paying for this maintenance can be very expensive, but it’s necessary because failure to do so can be dangerous for the equipment and employees. This is one shortcut you don’t want to take.

4. Quality

If metal laser cutting is not your focus, it is extremely challenging to maintain the same quality standards that professional metal bending companies can offer. It’s wise to outsource to a specialized metal cutting company that uses the best equipment and cutting-edge technology. This will guarantee superior value and quality in the products you receive, ensuring the best outcome for your projects.

5. Expertise

Skills

When it comes to custom metal fabrication, the skills of the metal fabricator are very important. The entire process of metal cutting and bending fabrication requires vast knowledge to perform every step with caution. While laser cutting is a popular and highly-regarded technique, many people do not know how to handle laser cutting equipment. There is a significant learning curve to navigate.

Design Help

If you’re new to laser cutting, it may be challenging to picture what the end product will look like. It’s likely that veteran CNC laser cutting operators have developed comprehensive knowledge from creating custom parts for customers of different industries. They can help you co-design and develop the customized parts and products you need. You are more likely to get help in optimally designing parts of your manufacturing needs with the help of qualified professionals.

Materials

The outcome of a project depends on what type of metal is being used. Professional laser cutter operators are experts in all metal materials and can suggest what type of metal will be best for your project. When outsourced, you can also save time researching what materials you’ll need and can rely on laser cutting professionals. We can find, purchase, and use the most appropriate material for your design.

Laser Cutting Outsourcing with Steelway

Businesses love laser cutting for many reasons. It’s precise and effective and can be used on a wide variety of materials. However, you can maximize these benefits by having your laser cutting outsourced by a team of experts.

Let Steelway Laser Cutting partner with you and see how our laser cutting services can benefit your organization.

We are confident that our advanced technology and collaborative staff will help your business achieve the best results possible.

To learn more about how you can add value to your business while cutting costs by choosing outsourced laser cutting, contact Steelway Laser Cutting today.

Article reviewed and approved by Director of Product Design – Derek McAvoy.